CATEGORIES

CONTACT US

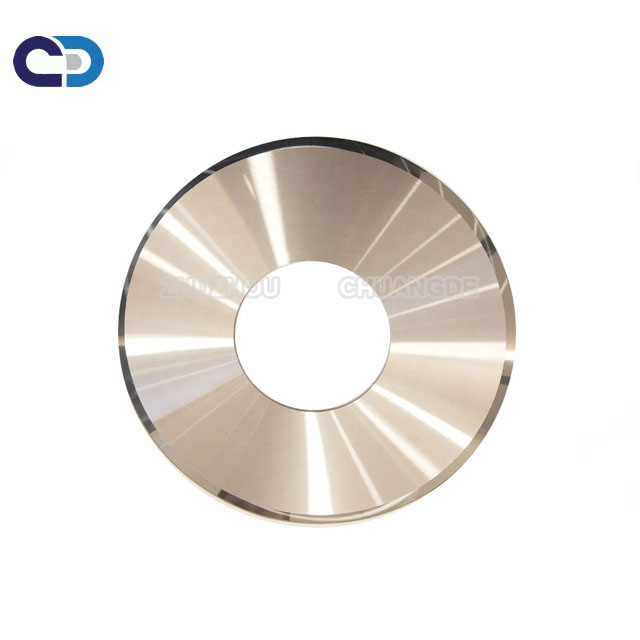

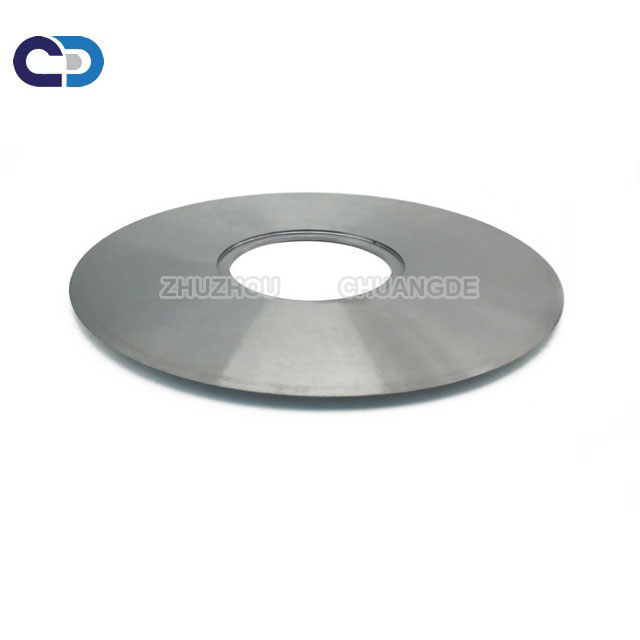

tungsten carbide slitting slitter knife circular blade for corrugated paper cutting

Email:

Email:

tungsten carbide slitting slitter knife circular blade for corrugated paper cutting

Tungsten carbide slitting slitter knife circular blade for corrugated paper cutting

Our blades are used for corrugated carton slitter scorer machine,cardboard slotting machine,carton printing machine etc.They can be made by tungsten carbide with long life working time.We have all standard size and also can customized as customers' requirements.

In addition,we can provide the grinding wheel for the blade,slotting blade and others blade used for carton ,tobacco machinery.

| Materials | Tungsten Carbide CD020, CD030, OEM | |||

| Thickness | 0.2-6mm or customized | |||

| Flatness | 0.003mm | |||

| Type of edge | single edge, double edge | |||

| HRA | 85-93 | |||

| Straightness | <0.1 | |||

| Surface roughness | Ra0.2 | |||

| Laser engraving | Done as requirement | |||

| Package | 10pcs/set,Simple packing/Plastic box packing/Blister packing | |||

| Main Size | OD(mm) | ID(mm) | Thickness(mm) | Cutting Edge |

| 300 | 112 | 1.4 | double | |

| 280 | 168 | 1.4 | double | |

| 265 | 112 | 1.3 | double | |

| 260 | 168 | 1.4 | double | |

| 260 | 140 | 1.4 | double | |

| 240 | 132 | 1.2 | double | |

| 230 | 110 | 1.3 | double | |

| 200 | 122 | 1.2 | double | |

| 140 | 46 | 1.2 | single | |

| 100 | 16 | 0.3 | single | |

| 85 | 16 | 0.25 | single | |

| 60 | 19 | 0.27 | single | |

| Size | Can be customized according to customer requirements | |||

| Advantages | 1, High quality raw materials. | |||

| 2. Durable & Long service life. | ||||

| 3. High precision. | ||||

| 4. Nice and solid packaging. | ||||

| 5. Excellent weather resistance and waterproof. | ||||

| Application | For paperboard/paper/cardboard/carton/Tobacco machine to cut. | |||

Grade of Tungsten Carbide Disc Blanks/Slitting Knife Carbide Circular Cutter Blade

we can provide many different grade raw material for all customers:

Grade | Properties & Applications | |||

Density | T.R.S | Hardness | ||

g/cm3 | MPα | HRA | ||

CD020 | 14.50 | 3000 | 91.8 | Sub-micron grain, apply to cutting corrugated board, chemical fiber, plastics, leather, battery pole pieces, all kinds of milling cutters and hole-machining tools. |

CD021 | 14.53 | 2800 | 90.5 | Fine grain, mainly used for woodworking blade and tobacco machine cutter. |

CD022 | 14.55 | 2700 | 89.5 | Mainly used for regular sealing ring, die, wear parts, mining tools and machining of non-ferrous cutting blades. |

CD025 | 14.10 | 3500 | 92.5 | Ultra-fine grain, apply to cutting corrugated board, paperboard, leather, composite, materials, machining of gray cast iron and heat-resisting alloy. |

CD030 | 14.10 | 3200 | 90.5 |

Sub-micron grain, superb abrasive resistance and toughness, apply to woodworking cutters, cutting corrugated board, battery pole pieces, etc. |

Application of Warranty Tungsten Carbide Disc Blanks/Slitting Knife Carbide Circular Cutter Blade

The carbide circular blades for Slitting Corrugated Board, carbide rotary blade for rubbers cutting, carbide blade for battery industry, carbide blades for Tobacco Machines, carbide circuit board cutting knife, carbide blades for metal cutting, carbide knife for Rewinder machines, carbide blades for chemical fiber cutting, carbide blades for printing industry, carbide milling cutter for paper industry, and carbide blades for other special range.

TUNGSTEN CARBIDE ROUND BLADES HAS DIFFERENT APPLICATION AND DIMENSION

Production Process of Warranty Tungsten Carbide Disc Blanks/Slitting Knife Carbide Circular Cutter Blade

To ensure the quality and the requirements of the drawings can be met before mass production

1st , Start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine

2nd, Before mass production, do a trial pressing and sintering using mould,

3rd, Check the appearances and the sizes of the samples with micrometer, projectors etc.

Testing process of Warranty Tungsten Carbide Disc Blanks/Slitting Knife Carbide Circular Cutter Blade

1st,Mass production press the raw materials to shape blanks,

Notes: all carbide blades blanks must be passed by semi finished inspection

2nd,Sinter blanks to finish (HIP) and finished products inspection,

Notes:10 sets of vacuum sintering furnace and 2set of HIP in the factory ensure the best quality and production capacity.

3rd,Cleaning/tumbling to make the carbide blades clean and nice surface.

Packing and Delivery of Warranty Tungsten Carbide Disc Blanks/Slitting Knife Carbide Circular Cutter Blade

step 1, wrapped carbide blades in paper to avoid carbide blade be broken

step 2, put the carbide blade in inner small carton box

step 3, put the inner box into outer carton and fill the carton with foamed plastic

step 4, wrap the carton with packaging tape

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy