CATEGORIES

CONTACT US

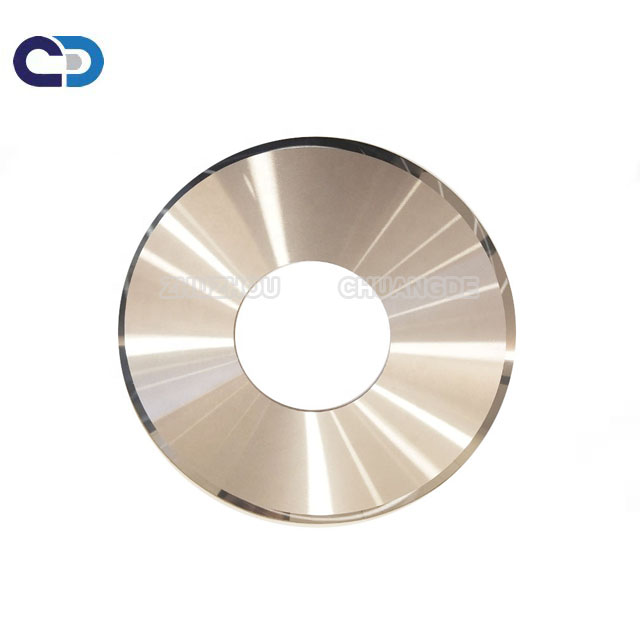

Tungsten Carbide Slitting Blade Circular Knives BHS for Cutting Paper

Email:

Email:

Tungsten Carbide Slitting Blade Circular Knives BHS for Cutting Paper

Product description of carbide disc cutting blade

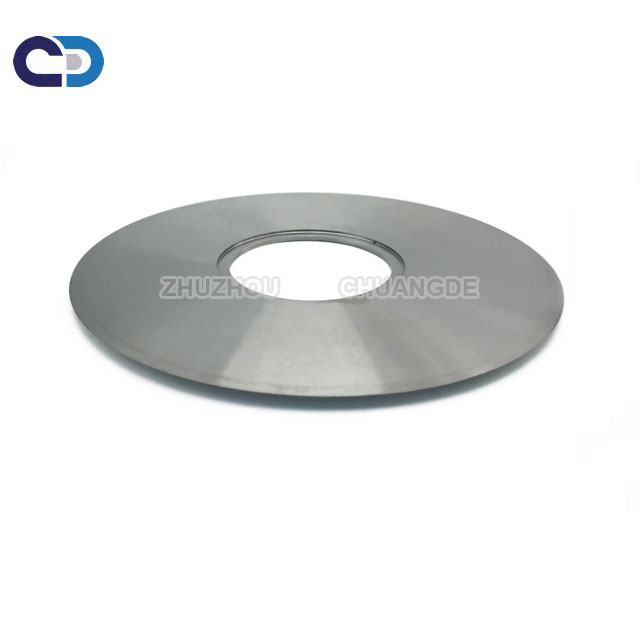

1, Our every carbide disc cutting blade can cut 6~7 million meter corrugated board.

2, This size is specially for BHS machine to cut corrugated sheet

3, All properties and size and tolerance, face treatment please see below details for you reference, also we can produce according to customers' requirement.

Grade | Grain size | Density | T.R.S | Hardness | Suitable for cutting |

g/cm3 | ≥ N/mm2 | HRA | |||

CD020 | ultrafine grain | 14.5 | 3300 | 91.5±0.5 | domestic machine to cut corrugated board, chemical fiber,leather,sheet metal,battery |

CD030 | ultrafine grain | 14.1 | 3500 | 90.5±0.5 | foreign machine to cut corrugated board |

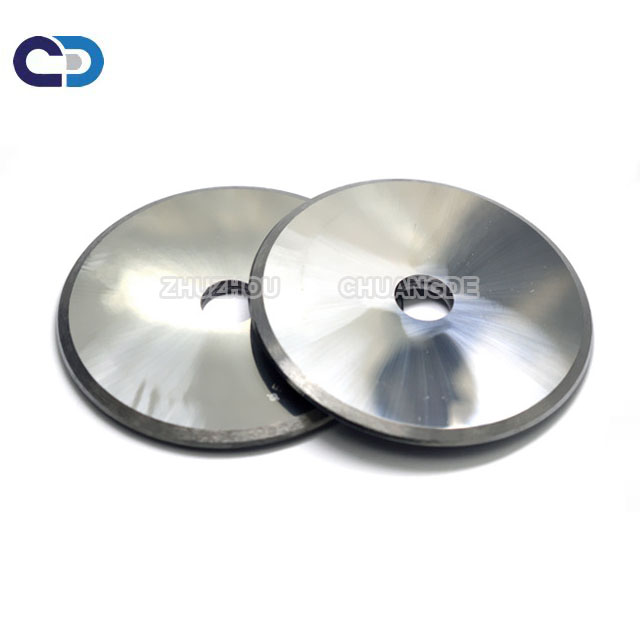

Product process of carbide disc cutting blade

1, after the order is confirmed, carbide disc cutting blade products will start to predouce a sample to test quality,if quality is not ok, we will analyze it untill we have confident that quality is good,ensure our customers will receive our best quality carbide disc cutting blade.

2, after testing sample is ok, we will start to produce bulk,first make raw material powder to ball grinding,then press to shape.

3, after pressing, we will add a semi-finished inspection,if semi-finished products are ok, then go to sinter, through sintering, every production process of carbide disc cutting blade have finished.

4, after sintering, we start to grind,inculding rough grinding, accurate grinding,surface flatness grinding, angel cutting grind ect

4, finished Inspection, including surface,tolerance, chemical and physical inspection ect

Application for Wholesale Factory Direct Tungsten Carbide Knives for Slitter Corrugated Board

Production and Inspection

1. WC powder

2. Ball grinding mill

3. Press

4. HIP sintering

5. Electric discharge machining(EDM)

6.Carving machine

All raw material are tested in terms of density ,hardness and T.R.S before using

Packing and Shipping

1. our worker will make sure your carbide circular blade clean before package.

2. rubber strip wrap sharp cutting edge to avoid edge broken.

3. put into plastic bag and styrofoam box to keep carbide circular blade steady when express deliver

4. add plastic foam into inner box for the whole carbide circular blade for sweet protection.

5. we will make export standard strong cartonn or plywood case package according to your needs.

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy