CATEGORIES

CONTACT US

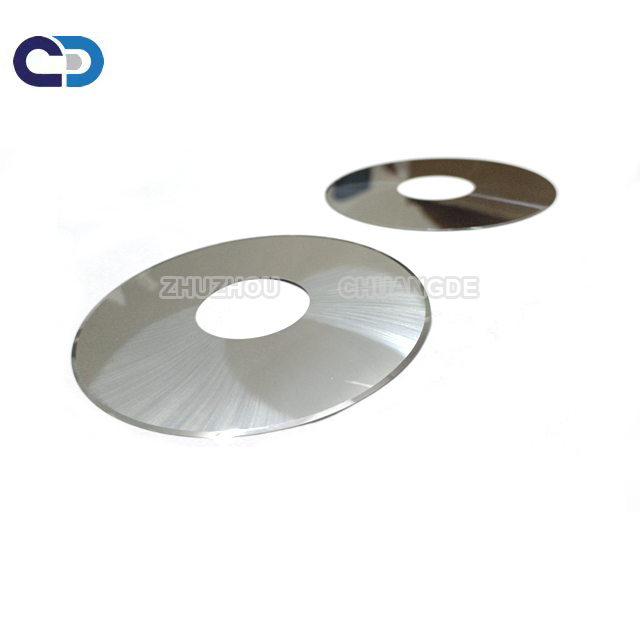

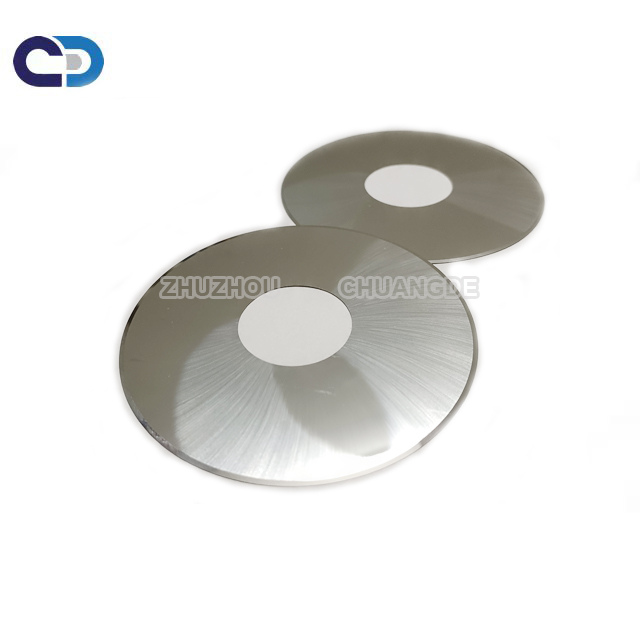

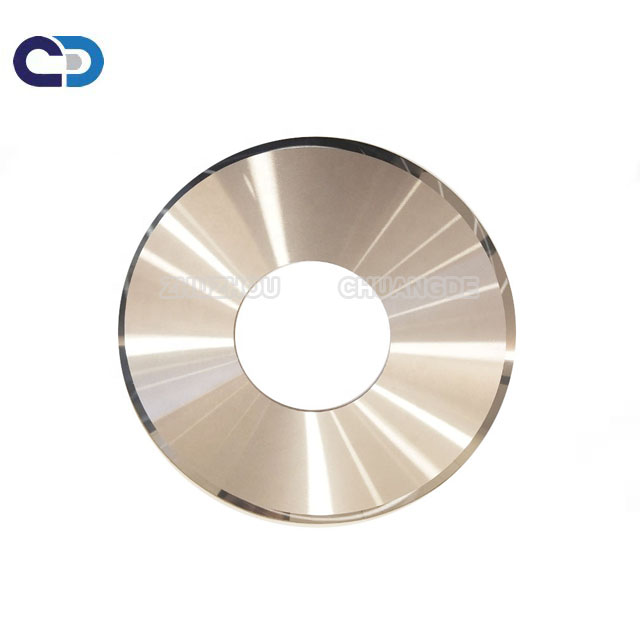

Manufacturer Wear-resistant Tungsten Carbide Disc Knives Round Blade For Tobacco Cutters

Email:

Email:

Manufacturer Wear-resistant Tungsten Carbide Disc Knives Round Blade For Tobacco Cutters

Product description

Material | 100% virgin raw material |

Grade | CD030 |

Size | Φ76.2*Φ25.4*0.25 |

Application | For tobacco cutters |

Place of origin | Zhuzhou,Hunan,China |

Package | 10pcs/box |

Basic characteristics of cemented carbide round blades

1. Hardness

Generally, the better the material, the higher the hardness obtained by quenching. If a common material is quenched to a very high hardness, the toughness of the round blade will be destroyed and the blade edge will crack. Therefore, the quench hardness of round inserts must depend on the material. The hardness of the round blade should be much greater than the hardness of the cutting material. Typically, the quench interval for heat treatment is HRC 55-64.

2. Wear resistance

The wear resistance of the blade is proportional to the hardness. The better the material used for round inserts, the higher the hardness and the better the wear resistance.

3. Heat resistance

Heat resistance refers to the hardness, toughness, strength and wear resistance of steel. They stay in a high temperature environment generated at high speed. Generally, the quality of a round blade is measured by the red hardness of the steel. The higher the red hardness, the higher the cutting speed the material can withstand.

4. Stability

Stability refers to the degree of crystallinity change of the slitting blade material after the blade is heat-treated. At present, the heat treatment methods of slitting machine blades include vacuum quenching, salt bath quenching, electric furnace quenching, etc. Different quenching methods have a great influence on the stability of the blade material.

Production and Inspection

1. WC powder

2. Ball grinding mill

3. Press

4. HIP sintering

5. Electric discharge machining(EDM)

6.Carving machine

All raw material are tested in terms of density ,hardness and T.R.S before using

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy