CATEGORIES

CONTACT US

tungsten carbide burr with all cut type and tooth shapes for machining surface profile

Email:

Email:

tungsten carbide burr with all cut type and tooth shapes for machining surface profile

Product description:

Tungsten carbide burr is used widely in the shipping construction, auto engine porting and foundry fabrication. With its high rotating speed and hardness, it can machine a lot of different materials like cast iron, carbon steel, alloy steel and nonferrous material. The high life service of the product is warranted for virgin and excellent raw material which is one of the most critical factors to the tools' life.

Our advantages:

1.Good tungsten carbide raw materials powder;

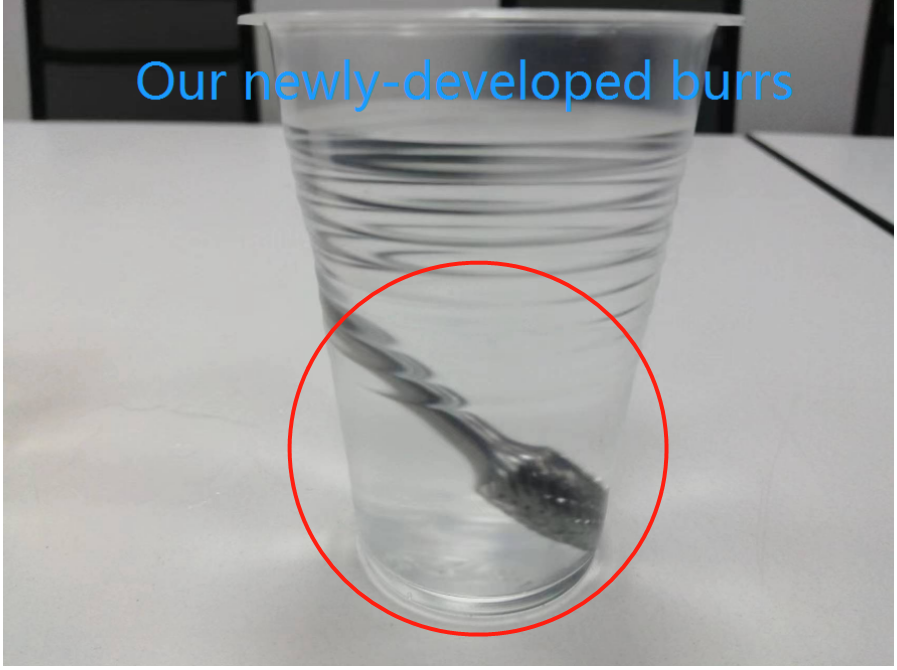

2. High performace of steel shank (GN steel) and good rust-proof property of whole burr;

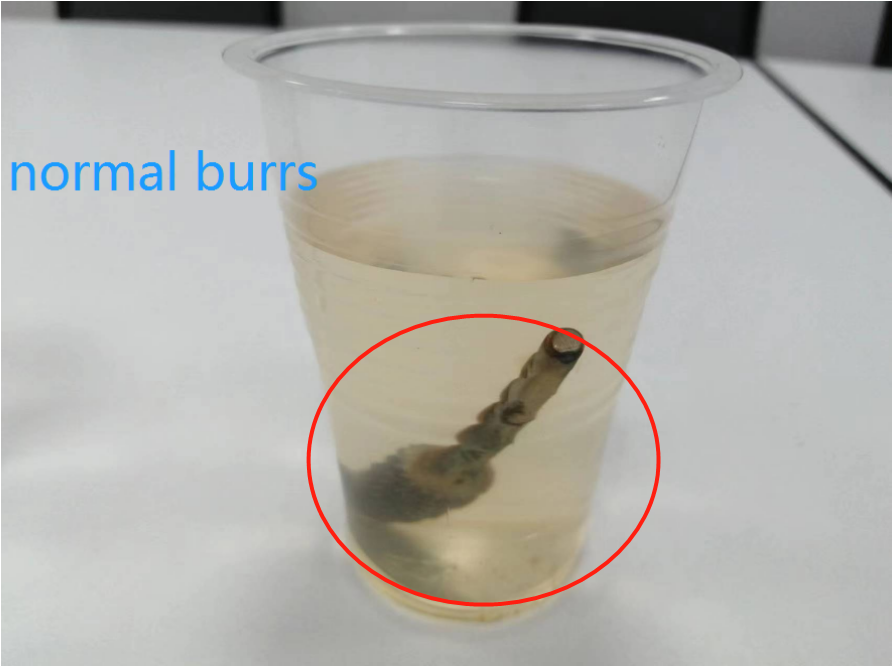

Our case testing of our new burrs compared with normal burrs keep in water for same long time,

testing results as belowing:

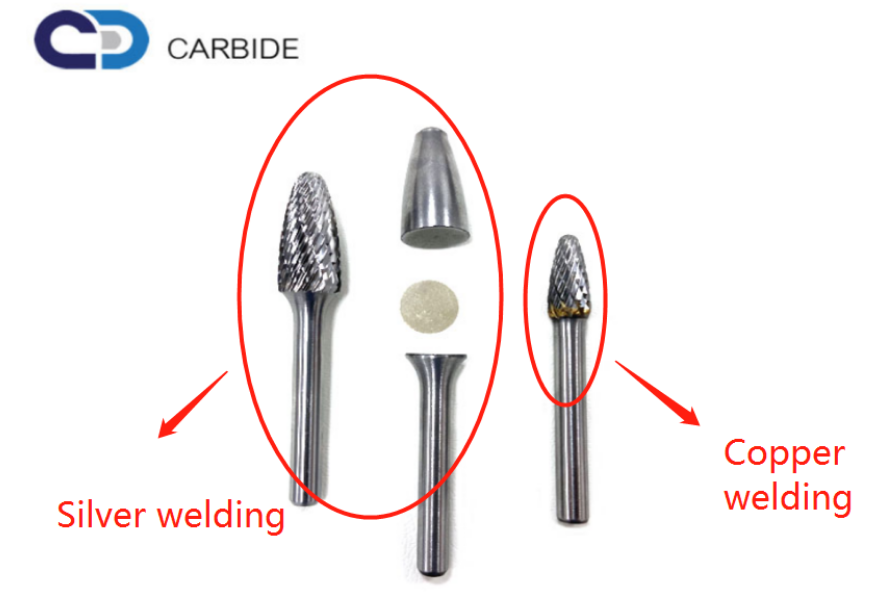

3. Silver welding making stable quality and good wear resistance, long life time.

why use silver welding not cooper welding and what are the advantages of our silver welding :

Reason: copper welding should process at a temperature which is at least 1200 degree centigrades, but tungsten carbide which composited of WC and Cobalt often sinter at 800-1000 degree centigrades, if temperature is too high, the cobalt will turn on liquid phase which will affect the performance of carbide. then burrs will easily break and worn out.

but silver welding not only can avoid those problems, also it can improve the concentricity when welding the carbide burr with steel shank.

Our types and sizes:

Applications:

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy