CATEGORIES

CONTACT US

Composite Welding Tungsten Carbide Rod Bar For Hard Facing Gold Copper bar

Email:

Email:

Composite Welding Tungsten Carbide Rod Bar For Hard Facing Gold Copper bar

Tungsten carbide welding rod bar for hard facing/ driling use golden color

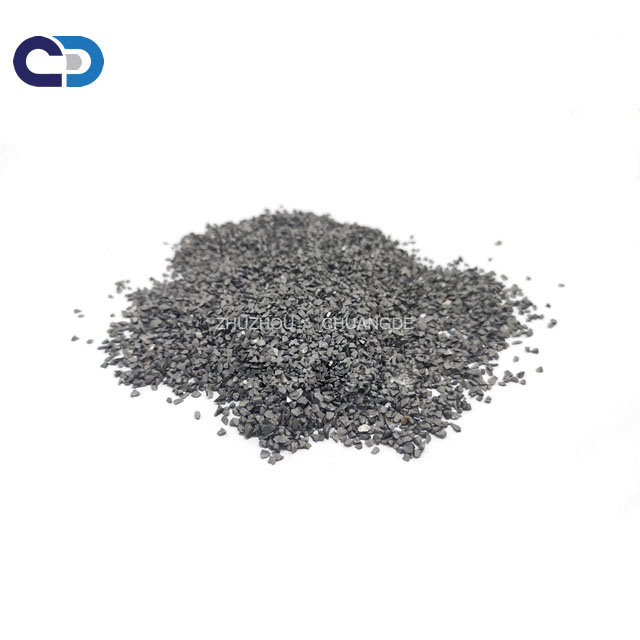

Copper carbide composite rods made of by sintering tungsten carbide scrap and elastic matrix alloy .Outer layer of the special flux and coloring is marking scrap grade,the composition of sintering tungsten carbide scrap is mainly CO and WC,The hardness is HRA 89~91,tire body matal is Ni and copper alloy,strength can up to 690MPa, hardness HB≥160.

Composition: NCu, tungsten carbide grits

Hardness: >160 HB

TRS: >690MPa

Tungsten Carbide Composite Rod Features:

Top-quality tungsten carbide;

Eight grades are available;

Excellent wear, corrosion, and abrasion resistance;

Consistent quality;

Competitive price;

Customization service.

| grade | size | scrap size (mm) | color |

| YD-9.5 | 9.5 | 9.5~6.5 | dark green |

| YD-8 | 8.0 | 8.0~6.5 | dark blue |

| YD-6.5 | 6.5 | 6.5~5.0 | red |

| YD-5 | 5.0 | 5.0~3.0 | yellow |

| YD-3 | 3.0 | 3.0~2.0 | pink |

| YD-10 nesh | 10 mesh | 10~18 mesh | light green |

| YD-18 mesh | 18 mesh | 18~30 mesh | light green |

| YD-30 mesh | 30 mesh | 30-50 mesh | light yellow |

Production of Copper Or Nickel Tungsten Carbide Rod Cemented Carbide Composite Welding Rods

The oxyacetylene butt, the operating process is as follows:

(1) clean up the workpiece, make the welding workpieces surface with metallic luster.

(2) the flat position of welding, therefore can use the appropriate clamping fixture for control of surfacing layer thickness, thick piece of available.

(3) with a neutral flame preheating, flame core not contact surface, the distance to 25 mm is advisable.

(4) carbide surfacing welding layer.With YD type electrode surfacing, the use of neutral flame (can be slightly carbonizing flame) tip is steady on the workpiece surface movement, the flame of the alloy electrode heating (be careful not to make flame cone tip contact alloy particles), tire body in the electrode alloy melt, carbide particles are also falling.Before the tire body of molten metal solidification, the particles arrange, can use left hand of the alloy electrode fingers, or another person holding a base electrode or pull rod on graphite rod in a quick stir particles, making them evenly aligned neatly.Surfacing layer thickness control according to the requirements of design.

(5) after the workpiece welding, where no ventilation, slow cooling, cannot quench, conditional usable asbestos blanket cover.

(6) the workpiece after cooling to room temperature, if necessary, grinding surface surfacing to required size and shape.

(7) clean up the workpiece, remove all splash, slag, etc.

Applications

Carbide composite welding rod is mainly used for surfacing welding the oil, mining, coal mining, geology, construction and other industries in some serious wear and tear or artifacts of both cutting.Such as: milling shoes, grinding, centralizer, reamer, drill pipe joints, hydraulic cutter, scraper, plough planer knives, core bit, piling drill, twist drill, etc.

Packing

step 1, wrapped carbide thread boring rods in paper to avoid carbide thread boring rods to broke

step 2, put the carbide thread boring rods in inner small carton box

step 3, put the inner box into outter carton and fill the carton with foamed plastic

step 4, wrap the carton with packaging tape

step 5, you can choose any delivery way such as DHL,TNT,UPS ect.

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy