CATEGORIES

CONTACT US

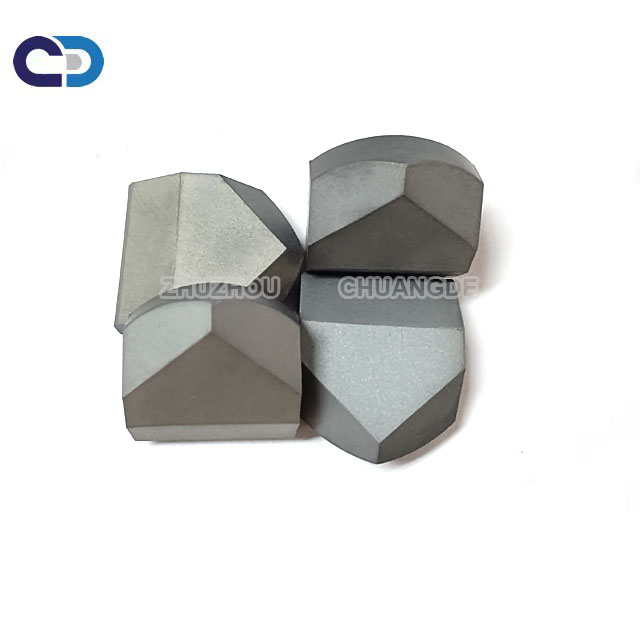

Tungsten carbide widia TBM shield cutter teeth tunnel boring machine

Email:

Email:

Tungsten carbide widia TBM shield cutter teeth tunnel boring machine

Tungsten carbide widia TBM shield cutter teeth tunnel boring machine

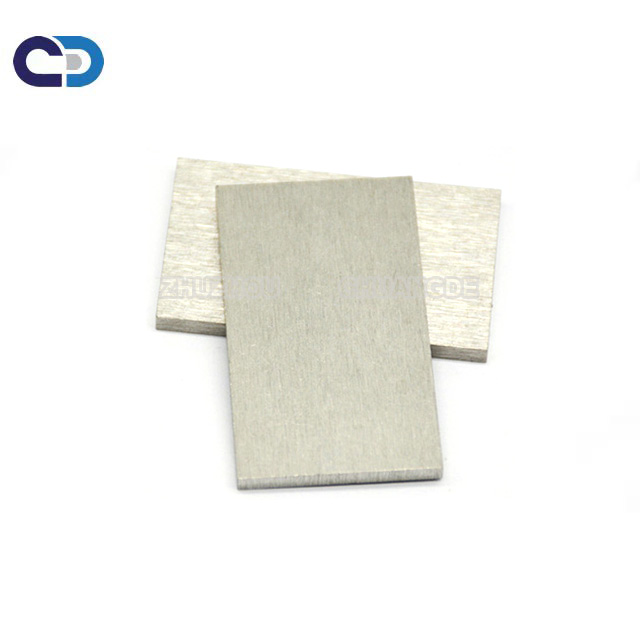

Item | Tungsten carbide TBM Shield cutter |

Grade | YG6, YG8, YK05,YG8C, YG9C, YG10C, YG11C, YG13C |

Sizes | customized or standard |

Brand | CD |

Country of Origin | Zhuzhou, China |

Usage | Tunnel Boring Machine |

Product advantages:

1. Wildly used in shield machine.

2. The specification based on the different part of cutters.

3. Easy to install and remove.

4. With high impact toughness, high abrasion resistance.

5. Stable physical ability, wide application field.

6. Top quality and long life time.

7. The appearance of fine workmanship etc.

Application of carbide shield cutter teeth

carbide shield cutter teeth are normally used for coring softer rock formations, overburden drilling, and cleaning of drill holes

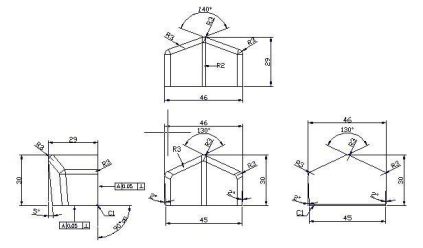

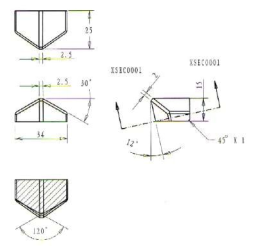

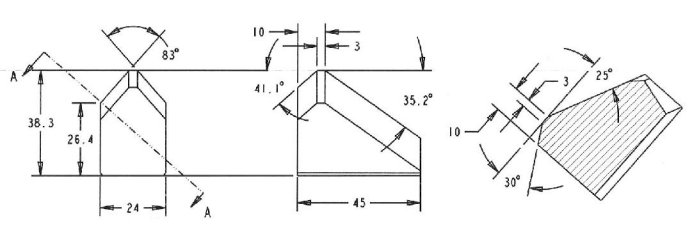

Drawing of tungsten carbide widia TBM shield cutter teeth tunnel boring machine

Density | T.R.S | Hardness | Performance & application recommended | |

g/cm3 | MPα | HRA | ||

CK10 | 14.7 | 2450 | 88.5 | Mostly used as the buttons of small and mediumsized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

CK15 | 14.7 | 2450 | 87.8 | Suitable to strips, conical buttons for rotary,percussion-resistant, geological prospecting,buttons, cut soft and medium hard formations. |

CK20 | 14.4 | 2550 | 87 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

CK25 | 14.5 | 2600 | 87.5 | Primarily for the buttons and inserts of rotary percussion bits to cut medium hard and very hard formations. |

CK30 | 14.4 | 2600 | 87 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

CK40 | 14.2 | 2650 | 86.5 | Predominatly for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and vey hard formations. |

CK50 | 14 | 2700 | 86.5 | For oil cone drill bits, for medium soft and medium -hard rocks. |

Our advantages:

1. Professional manufacture for tungsten carbide with more than 15 years’ experience. All products have passed the ISO9001 certifications.2. We have our own factory to produce the molds and products, so the delivery is fast. Also we have the professional sales teams to satisfy you well.

3. All products go through in-process and final inspection. Strictly and complete quality control system.

4. Made from 100% virgin material, stable and reliable quality.

5. We can accept order of all kinds of special designed products of tungsten carbide.

6. Various payment terms and delivery methods supported.

7. Sample and free online technical service is available.

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy