CATEGORIES

CONTACT US

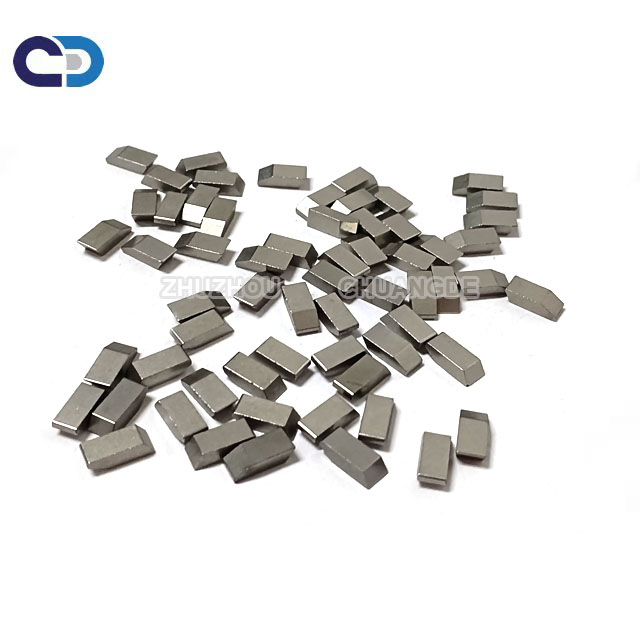

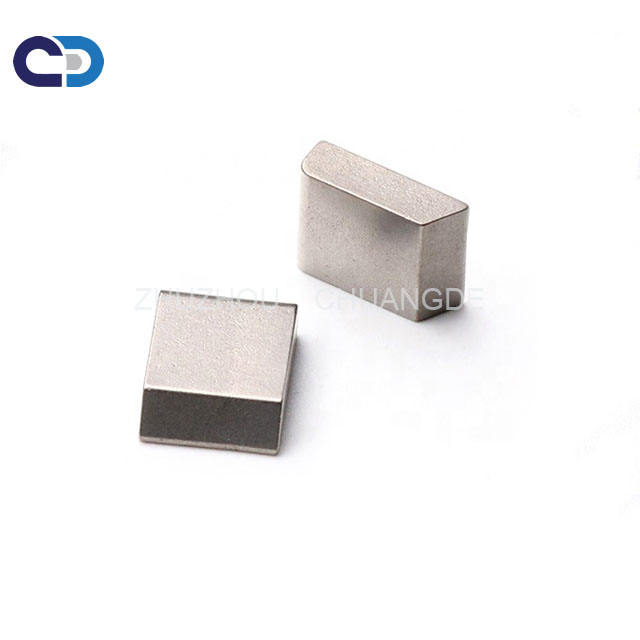

P40 Tungsten carbide Saw Tips teeth for steel cutting saw blade

Email:

Email:

P40 Tungsten carbide Saw Tips teeth for steel cutting saw blade

Characteristic

The main composition of tungsten Carbide Saw tips is tungsten carbide powders and cobalt powders or Nickel powders. With its wear resistant and corrosion resistant ability, tungsten carbide nowadays is widely used in many areas such as:cutting tools, moulds,oil and automobile industry

Advantage

1. 100% virgin raw material

2. Excellent wear-resistance

3. High impact resistance

4. Stable chemical properties

5. Careful surface treatment and perfect appearance

6. Easier to braze, and long service time

7. Made by precision moulds, better diemsional accuracy and uniform

8. Various types and grades available

Application of Tungsten carbide tips/carbide saw tips/circular saw tips

Tungsten carbide saw tip is used as the tips for the TCT saw blade for cutting all kinds of steel . It can give much more excellent performance than HSS.We have grade to gain the tenacity of the saw tips that will not break soon and can extend lifetime of the products .

Grade and application

| Grade | Density g/cm³ | T.R.S N/m㎡ | Hardness HRA | Application | ISO |

| CYTD15 | 11.0-11.7 | 1150 | 91 | Suitable for carbon steel and alloy steel processing, rough turning, semi-finish turning and finish turning in continuous cutting, small section finish turning in intermittent cutting, semi-finish milling and finish milling of continuous surface, coarse and fine hole enlargement. | CP10 |

| CYTD14 | 11.2-12.0 | 1200 | 90.0 | Suitable for rough machining in carbon steel, alloy steel processing, rough machining in uneven section and continuous cutting, semi-finish turning and finish turning in intermittent cutting, rough milling in continuous section, and drilling and rough enlargement of casting hole. | CP20 |

| CYTD5 | 12.5-13.2 | 1400 | 89.5 | Suitable for rough turning, rough planing, semi-finish planing, rough milling and drilling of discontinuous surfaces when carbon steel and alloy steel (including steel forgings, stamping parts and casting skins) are machined with uneven sections and discontinuous cutting. | CP30 |

| CYSD30 | 12.45 | 1800 | 91.0 | Belong to ultra-fine grain alloy, which is suitable for milling all kinds of steel, especially alloy steel, with high efficiency. | CP25/CP30 |

| CYSD25 | 12.8-13.2 | 2000 | 91.0 | Suitable for rough turning, milling and planing of carbon steel, cast steel, high manganese steel, high strength steel and alloy steel. | CP40/CM20/CM30 |

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy