CATEGORIES

CONTACT US

K10 YG6 YG6X tungsten cemented carbide saw blade teeth tips

Email:

Email:

K10 YG6 YG6X tungsten cemented carbide saw blade teeth tips

Product

Tungsten Carbide Woodworking Saw Blade Tips

Cemented Carbide Saw Teeth/ Tungsten Carbide Saw tips For Rip Saw

Plywood Sawing Blade Anti-Nail Cemented Carbide Saw Teeth/ Carbide Sawing Tips

Easy to Brazed by Manual brazing or Automatic Welding Cemented Carbide Saw Tip

Tungsten carbide saw tip is used as the tips for the TCT saw blade for cutting all kinds of original wood, hard wood, HDF, MDF, plywood, particle board, laminated board, composite material, grass, aluminum and metals. It can give much more excellent performance than HSS .

Grade and application

Grade | ISO | Density g/cm3 | Hardness HRA | T.R.S N/mm2 | Application |

YM3A | K01 | 15.1 | 94.0 | ≥1700 | Shaving board, laminated board and HDF etc. |

YM3X | K05 | 15.2 | 92.0 | ≥1800 | |

YM6A | K10 | 14.85 | 92.5 | 2200 | Hardwood, MDF, HDF, copper and aluminum. |

YM6X | K10 | 14.9 | 91.5 | 2300 | Ordinary wood, PVC, copper and aluminum. |

YM8X | K20 | 14.65 | 91.5 | 2900 | Carbon steel, copper and aluminum. |

YM10X | K30 | 14.45 | 90.5 | 3000 | Cork and building templates. |

YM10T |

K30 |

14.4 |

91.8 |

3400 | All kinds of wood, copper, aluminum and other non-ferrous metals, highly optimized for general use. |

YM2T | K30 | 14.3 | 92.2 | 2500 | Stainless steel, color steel plate, etc. |

YM6 |

K10 |

14.9 |

90.5 |

2400 | Hard wood, original wood, aluminum section bar, brass rod and cast iron. |

YM8 |

K20 |

14.7 |

89.8 |

2800 | Dry wood, soft wood, aluminum and brass, graphite and grass. |

YM8C |

K20 |

14.7 |

88.5 |

2600 | Soft and dry wood, general wood with loose knot, man-made marble. Ceramics and grass. |

YM9C | K20- K30 |

14.6 |

88.0 |

2700 | For debarking and cutting of frozen wood, soft wood and original wood. |

YM11C | K30- K40 |

14.4 |

87.0 |

2700 | Hard wood, non-ferrous metal, granite and marble. |

YM15C |

K40 |

14.0 |

86.0 |

3100 | For debarking and cutting of frozen wood, soft wood and original wood. |

CD501 | P30 | 12.5 | 92.5 | ≥2000 | Steel tile, steel angle, sheet iron. |

CD503 | P30 | 12.3 | 92.0 | ≥1900 | Steel tile, steel angle, sheet iron. |

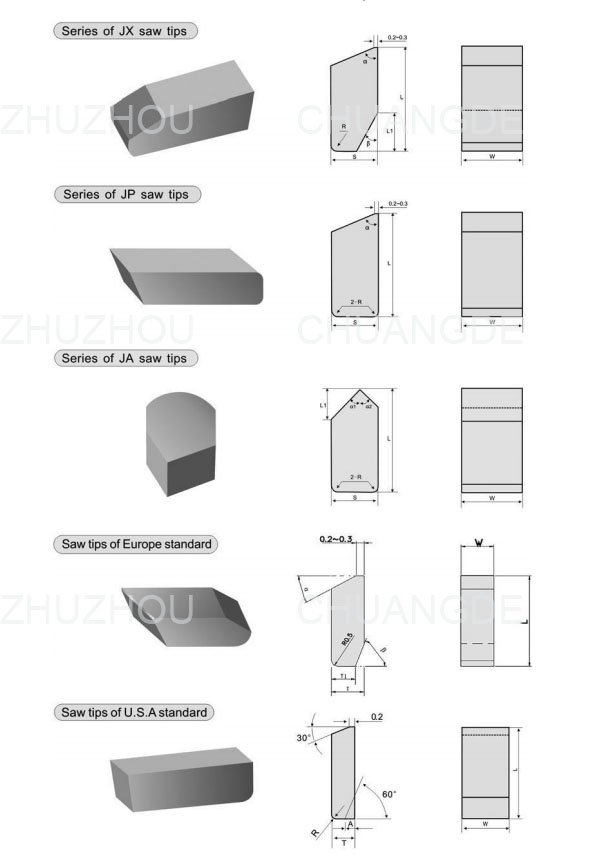

DIMENSION (MM) (Please send us drawing to confirm )

Tolerance control standard request

(Length)(mm) | (Width)(mm) | (Thickness)(mm) | ||

L | Width ranges | TOL | TOL | TOL |

≤5 | W≤2 | ±0.05 | +0.06 -0.04 |

±0.05 |

2 | ±0.06 | |||

3.5≤W≤5 | ±0.07 | |||

5~7 | W≤2 | ±0.06 | +0.08 -0.04 |

±0.05 |

2 | ±0.07 | |||

4≤W≤6 | ±0.08 | |||

7~9 | W≤3 | ±0.08 | +0.08 -0.04 |

±0.06 |

3 | ±0.10 | |||

5≤W≤8 | ±0.12 | |||

9~13 | W≤3.5 | ±0.10 | +0.08 -0.04 |

±0.06 |

3.5 | ±0.12 | |||

6≤W≤10 | ±0.15 | |||

13~17 | W≤4 | ±0.12 | +0.10 -0.05 |

±0.07 |

4 | ±0.15 | |||

7≤W≤14 | ±0.18 | |||

17~20 | W≤4.5 | ±0.12 |

+0.12 -0.06 |

±0.08 |

4.5 | ±0.18 | |||

7≤W≤15 | ±0.20 | |||

Advantage

1.Strong production capacity. We own mature production technology, process, various TPA press, large tonnage of hydraulic press and HIP furnace from Germany , ensuring pressing(TPA ) quality and sintering capacity achieving 1 ton per time. We can guarantee uniformity and stability of mass production.

2.Strong R&D team. Professional engineers serve for clients, recommending product and grades as per your applications. They also offer best after-sale service.

3.Strong Mould R&D team. They support customization of products as per requirements, and ensure high working efficiency and product quality.

4.Successful cooperate case: We cooperate with clients in domestic and abroad, and get good feedback from them.

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy