CATEGORIES

CONTACT US

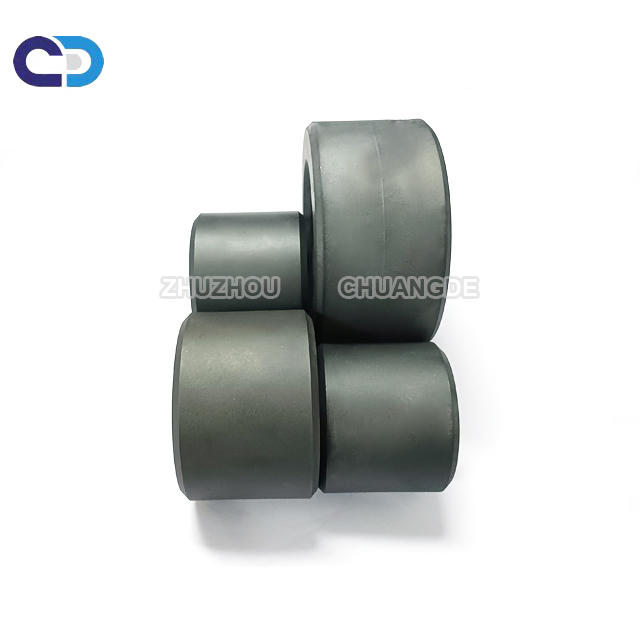

Hard metal widia cemented carbide ring rolls tungsten roller rings

Email:

Email:

Hard metal widia cemented carbide ring rolls tungsten roller rings

Hard metal widia cemented carbide rolls tungsten roller rings

Product Description

Tungsten carbide RO/RT/CA rollers, used to produce smooth or ribbed wire for the construction field. YG15 and YGH30 is the most common material grade for cold rolling.

| Item Name : | Best Price for Tungsten Carbide Rolling Mill 150*90*20 PR5 |

| Grade : | YG15 YG20 YGR45 |

| Hardness : | wire size from 4.0mm-16mm |

| Cobalt % : | +/-0.1mm |

| Grain Size : | coarse, fine, ultra |

| Usage : | cold rolling mills, hot rolling mills |

| Logo : | cold rolling mills, hot rolling mills |

| Package : | as per your requirement. |

The cemented carbide roll ring, also known as the tungsten carbide alloy roll ring, is an important component for the consumption of steel bars and wire rods, and is closely related to the apparent quality, dimensional accuracy and cost of the rolled steel.

Carbide roller rings have good turnability, no need for special lathes, and existing common lathes can be used for groove turning of roll rings. For turning, the cutter head can be made of high hardness carbide tool.

Tungsten carbide is a kind of hard alloy, the main components is tungsten carbide and cobalt, the hardness can reach 89~95HRA, with a series of excellent properties such as high hardness, high wear resistance, high strength, high toughness, high heat resistance and high corrosion resistance.

Advantages

1. good toughness

2. resistant wearing

3. high thermal conductivity

4. a comprehensive range of types

2.Grade and Size

Grade & Mechaical Properities

Nickel Grade Chart

Grade | Binder(Wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

YN6 | 6 | 14.7 | 89.5 | 1460 |

YN6X | 6 | 14.8 | 90.5 | 1400 |

YN6A | 6 | 14.8 | 91.0 | 1480 |

YN8 | 8 | 14.6 | 88.5 | 1710 |

Cobolt Grade Chart

Grade | Binder(Wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

YG6 | 6 | 14.8 | 90 | 2400 |

YG6X | 6 | 14.9 | 91 | 2300 |

YG6A | 6 | 14.9 | 92 | 2000 |

YG8 | 8 | 14.7 | 89.5 | 2800 |

YG12 | 12 | 14.2 | 88 | 2900 |

YG15 | 15 | 14.0 | 87 | 3000 |

YG20 | 20 | 13.5 | 85.5 | 2850 |

| No. | Outer diameter (mm) | Inner diameter (mm) | Height (mm) |

| 1 | 70 | 60 | 12 |

| 2 | 80 | 70 | 12 |

| 3 | 90 | 82 | 12 |

| 4 | 90 | 85 | 8 |

| 5 | 95 | 90 | 5.5 |

| 6 | 100 | 90 | 12 |

| 7 | 110 | 100 | 12 |

| 8 | 120 | 110 | 12 |

| 9 | 130 | 120 | 12 |

| 10 | 135 | 130 | 5.5 |

| 11 | 165 | 155 | 16 |

| 12 | 150 | 140 | 15 |

| 13 | Other customized size is also available | ||

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy