CATEGORIES

CONTACT US

Chinese OEM&ODE High Quality wear-resistance corrosion-resistance tungsten carbide valves seats

Email:

Email:

Chinese OEM&ODE High Quality wear-resistance corrosion-resistance tungsten carbide valves seats

Product Description

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer's application.

3. we have professional advanced production line and inspeciton equipments to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

Material Grade List

| ZHUZHOU CHUANGDE GRADE PERFORMANCE | |||||

| Grade | Density | Hardness | TRS | 矫顽磁力Coercive force | 钴磁 CO Magnet |

| g/cm3 | HV3(HRA) | MPa | KA/m | % | |

| CD6 | 14.85~15.05 | ≥89.50 | ≥2400 | 12.0~15.9 | 4.9~5.9 |

| CD6X | 14.85~15.05 | ≥91.00 | ≥2300 | 19.2~25.7 | 4.9~5.9 |

| CD8 | 14.65~14.85 | ≥89.00 | ≥2750 | 10.2~15.0 | 6.5~7.7 |

| CD8C | 14.55~14.75 | ≥87.50 | ≥2000 | 7.6~9.6 | 7.1~8.2 |

| CD8.2 | 14.50~14.80 | ≥89.00 | ≥2800 | 9.5~13.0 | 7.0~7.8 |

| YU08 | 14.56~14.65 | ≥1900 | ≥4000 | 34.0~43.0 | 6.3~7.7 |

| YT5 | 12.90~13.10 | ≥89.50 | ≥1560 | 8.5~13.5 | 8.0~9.2 |

| YT14 | 11.35~11.55 | ≥90.50 | ≥1400 | 10.5~15.4 | 7.3~8.1 |

| YT15 | 11.15~11.35 | ≥91.00 | ≥1300 | 11.0~15.5 | 5.0~6.2 |

| YW1 | 13.15~13.35 | ≥91.50 | ≥1290 | 16.0~22.5 | 5.5~6.2 |

| YW2 | 13.05~13.25 | ≥90.50 | ≥1460 | 13.0~20.0 | 7.4~8.2 |

| YW3 | 12.90~13.10 | ≥92.00 | ≥1390 | 16.5~21.8 | 5.5~6.1 |

| CD11 | 14.30~14.50 | ≥87.00 | ≥2400 | 8.0~13.0 | 9.5~11.4 |

| CD11C | 14.20~14.40 | ≥86.50 | ≥2700 | 6.0~8.0 | 9.5~11.4 |

| CD11C-N | 14.35~14.55 | 87.50~89.00 | 2600~2760 | 7.2~11.0 | 8.6~10.4 |

| CD15 | 13.95~14.15 | ≥86.50 | ≥2900 | 7.6~10.8 | 12.5~14.6 |

| CD16C | 13.75~13.95 | ≥84.00 | ≥3000 | 4.8~6.4 | 14.1~16.4 |

| CD20 | 13.45~13.65 | ≥83.50 | ≥2800 | 7.0~8.9 | 18.0~19.8 |

| CD20C | 13.40~13.60 | ≥82.00 | ≥2900 | 3.2~4.8 | 16.7~19.8 |

| CD25 | 12.90~13.10 | ≥82.00 | ≥3200 | 4.5~5.5 | 19.5~22.5 |

| CD2T | 14.35~14.55 | ≥91.50 | ≥2500 | 23.0~30.0 | 8.2~9.5 |

| YK20 | 14.40~14.60 | ≥86.00 | ≥2460 | 5.5~8.3 | 8.8~9.8 |

| YK25 | 14.40~14.60 | ≥86.50 | ≥2550 | 6.0~8.3 | 8.8~9.8 |

| YK15.1 | 14.65~14.85 | ≥87.50 | ≥2310 | 8.0~12.9 | 7.0~7.9 |

| YK40 | 14.10~14.30 | ≥85.50 | ≥2400 | 5.5~7.2 | 11.0~12.4 |

| YK50 | 13.90~14.10 | ≥85.00 | ≥2350 | 5.5~6.5 | 12.8~14.3 |

| YL10.2 | 14.40~14.60 | 1550~1650 | ≥3000 | 20.0~26.0 | 6.3~7.1 |

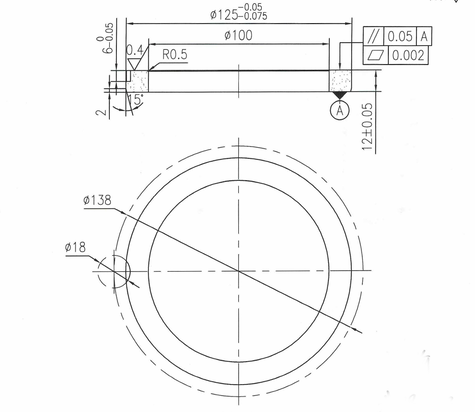

Drawing

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy