類別

聯絡我們

G40 G50 G5 YG25 Tungsten carbide round die for manufacturing steel bars

電子郵件:

電子郵件:

G40 G50 G5 YG25 Tungsten carbide round die for manufacturing steel bars

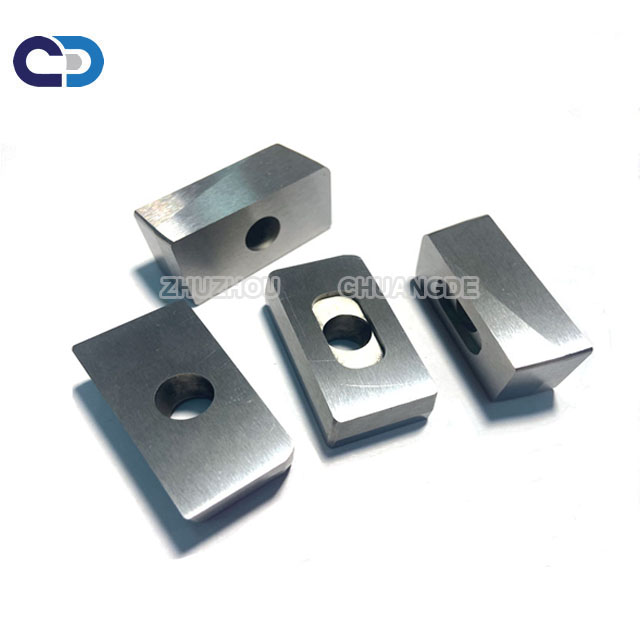

Description of product of G40 G50 G5 YG25 Tungsten carbide round die for manufacturing steel bars

1.Corrosion cemented carbide: cemented carbide electric corrosion layer is thinner, the micro defect of machined surface is reduced, and the surface quality of cemented carbide is improved.

2. Grain structure: tungsten carbide is more uniform, more rounded corners, more uniform stress distribution, improve cemented carbide

Features of G40 G50 G5 YG25 Tungsten carbide round die for manufacturing steel bars

1) Extension of die life and stability of life

By controlling the particle size distribution of WC, can make the plastic deformation and reduce the load of thecemented carbide to improve the compressive strength and fracture toughness, delaying the occurrence and propagation of cracks of the mould process, long service life, and has a very high consistency .

2) Bite and adhesion decreased considerably

High temperature single crystal WC was used to strengthen the binding of crystalline structure and effectively strengthen the cobalt phase, thus effectively inhibiting the cracking of the material .

3) The corrosion resistance and electrical resistance of the cemented carbide are improved

Because of the strengthening of the cobalt phase, the corrosion resistance of the cemented carbide is greatly improved, so that the cemented carbide is suitable for discharge machining.

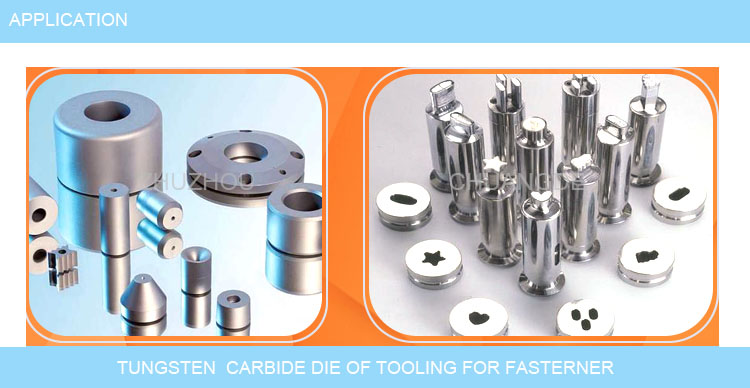

Applications :

Tungsten carbide pellets dies are widely used in cold heading,forging,stamping and punching dies for maufacturing round nuts, screw caps, bolts, cans and it can be used for manufacturing steel rods .

| Grade | Density g/cm3 | Hardness HRA | T.R.S Mpa | Performance&application recommended |

| YG20 | 13.5 | 85.5 | 2800 | It is suitable for manufacturing punching dies for watch parts,leaf spring of musical instrument,battery jars,small sized steel balls,screws,screw caps,etc |

| YG18C | 13.7 | 84 | 2800 | It is suitable for impact-resistant forging dies,hot-forging dies and finishing rollers |

| YG20C | 13.5 | 83 | 2850 | It is suitable for wear resistant or impact resistant dies |

| YG22C | 13.3 | 82 | 2900 | It is suitable for nut forming dies and high impact-resistant dies |

| YG25C | 13.1 | 81.5 | 3000 | It is suitable for stainless screw dies and semifinishing rollers |

| Other grades and sizes can be offered as per customers' requirement | ||||

Our Advantages :

1.Strong Mould R&D team. We support product customization as per specific requirements, ensure high working efficiency with good product quality .

2.Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

3.Strong R&D team. Professional engineers serve for clients, recommend products and grades as per your applications. We also offer after-sale service .

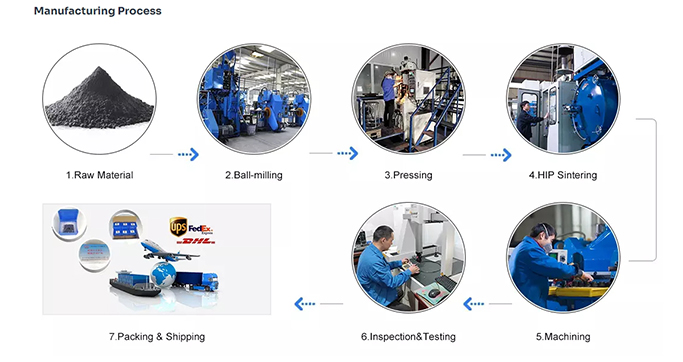

4.100% raw material for production.6. Hip sintered, reliable hardness, durable wear resistance

5. Various sizes, carbide grade and full types available

6. Competitive price with on-time delivery

7. Customized product as per drawing and small order accepted,professional and in-time technical support .

常問問題:

Q1: 你們是工廠還是貿易公司?

我們是一家擁有 12 年生產經驗的工廠。

Q2: 你們的工廠位於哪裡?

我們位於湖南省株洲市,那裡是碳化鎢基地。

Q3: 價格有競爭力嗎?

我們有自己的工廠。憑藉強大的生產和分銷系統,我們承諾為客戶提供最具競爭力的價格。

Q4: 產品品質好嗎?

是的。所有產品在批量生產前都會進行測試,我們將在發貨前檢查物理性能、形狀和公差,以確保產品合格。

請隨時與我聯絡:

艾米

銷售經理

株洲創德硬質合金有限公司

215, building 1, International Students Pioneer Park,

株洲市天元區泰山路。

電子郵件:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/微信/Skype : 0086 13786352688

相關產品

給我們發郵件