類別

聯絡我們

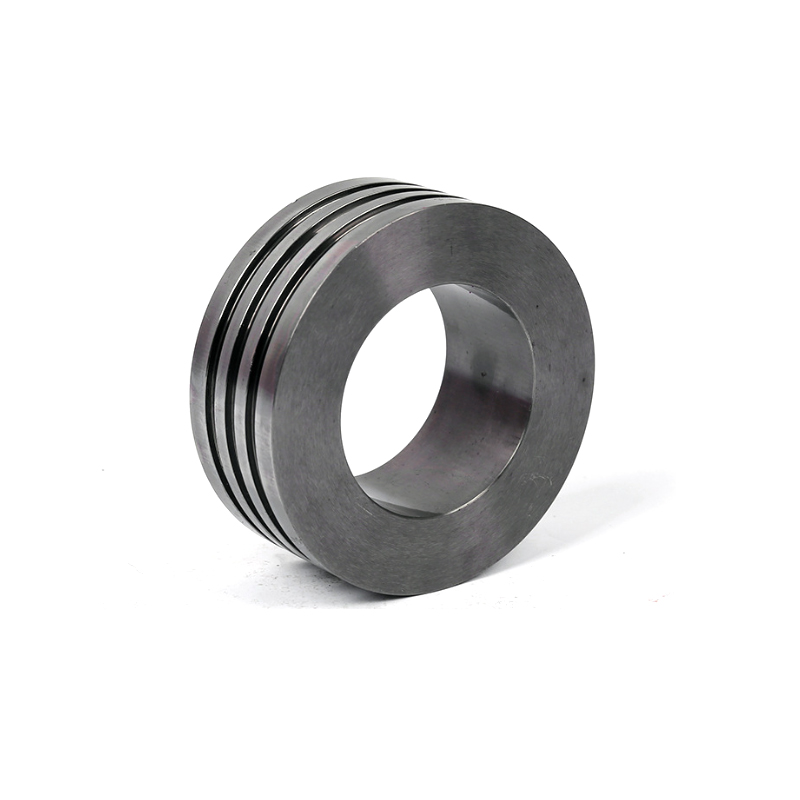

Good wear resistance customized cemented carbide rolls tungsten roller rings

電子郵件:

電子郵件:

Good wear resistance customized cemented carbide rolls tungsten roller rings

Good wear resistance customized cemented carbide rolls tungsten roller rings

1.Our rolls include oval reducing(RO),round reducing(RT),forming(FO)profiling(PR),sizing(CA).Other types are also available as per your requirements.

2.The rolling volume reaches 800-1500 tons one time, which is 20-50times higher than that of ordinary tool steel.

3.It can be used repeatedly by grinding, which greatly reduces the cost and significantly improves the benefit and efficiency.

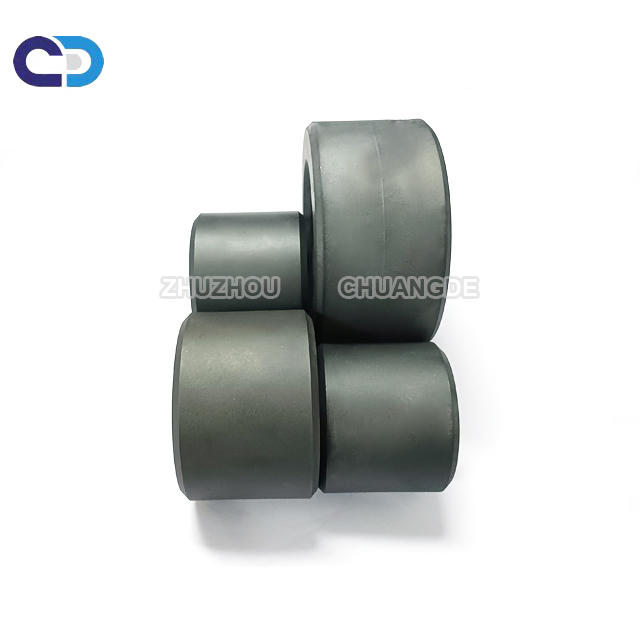

Name: Tungsten carbide wire rolls

Material : Tungsten carbide, hard metal, hard alloy,tungsten steel

Composition :Tungsten carbide – TC: 80-92%, Binder – Ni+Co+Cr: 8-20%

Density: 14.0-14.8g/cm3

Hardness: HRA87-92

Features,Advantages: Wear resistant, corrosion resistant, impact resistant

Size Ranges: Outter Dia:800mm, Inner Dia≤700mm, Thickness≤400mm

Roll Types : FO,RO,RT,CA,PR

Applications(Hot Roll) Aluminium and copper wire rod reduction rollers

Applications(Cold Roll )Sizing, Forming reducing and profiling rolls are made of tungsten carbide or steel and are used to produce smooth or ribbed wire for the construction reinforcement field.

Tungsten carbide is a kind of hard alloy, the main components is tungsten carbide and cobalt, the hardness can reach 89~95HRA, with a series of excellent properties such as high hardness, high wear resistance, high strength, high toughness, high heat resistance and high corrosion resistance.

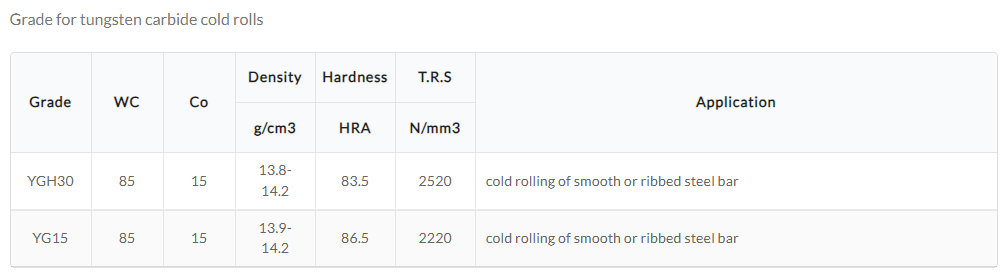

Grade and Size

Grade & Mechaical Properities

Nickel Grade Chart

Grade | Binder(Wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

YN6 | 6 | 14.7 | 89.5 | 1460 |

YN6X | 6 | 14.8 | 90.5 | 1400 |

YN6A | 6 | 14.8 | 91.0 | 1480 |

YN8 | 8 | 14.6 | 88.5 | 1710 |

Cobolt Grade Chart

Grade | Binder(Wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

YG6 | 6 | 14.8 | 90 | 2400 |

YG6X | 6 | 14.9 | 91 | 2300 |

YG6A | 6 | 14.9 | 92 | 2000 |

YG8 | 8 | 14.7 | 89.5 | 2800 |

YG12 | 12 | 14.2 | 88 | 2900 |

YG15 | 15 | 14.0 | 87 | 3000 |

YG20 | 20 | 13.5 | 85.5 | 2850 |

| No. | Outer diameter (mm) | Inner diameter (mm) | Height (mm) |

| 1 | 70 | 60 | 12 |

| 2 | 80 | 70 | 12 |

| 3 | 90 | 82 | 12 |

| 4 | 90 | 85 | 8 |

| 5 | 95 | 90 | 5.5 |

| 6 | 100 | 90 | 12 |

| 7 | 110 | 100 | 12 |

| 8 | 120 | 110 | 12 |

| 9 | 130 | 120 | 12 |

| 10 | 135 | 130 | 5.5 |

| 11 | 165 | 155 | 16 |

| 12 | 150 | 140 | 15 |

| 13 | Other customized size is also available | ||

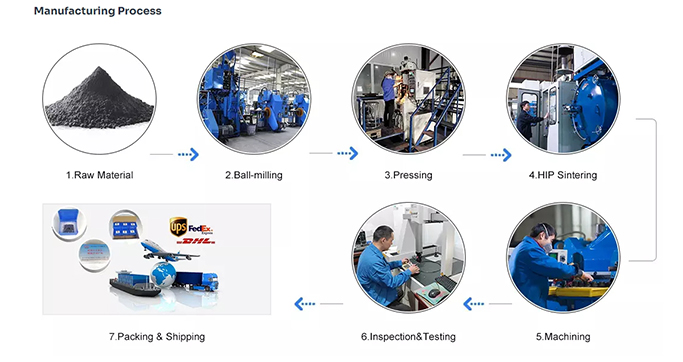

How to make tungsten carbide rolls

powder milling → formula according to grade→ wet grinding → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain a mixture → granulating → pressing → forming → Sintering →preforms→rough machining by flat grinding→non-destructive ultrasonic flaw detection →finishing machining by flat grinding→internal grinding →external grinding→chamfering→notching machining→laser marking→inspection →packing → Storage

常問問題:

Q1: 你們是工廠還是貿易公司?

我們是一家擁有 12 年生產經驗的工廠。

Q2: 你們的工廠位於哪裡?

我們位於湖南省株洲市,那裡是碳化鎢基地。

Q3: 價格有競爭力嗎?

我們有自己的工廠。憑藉強大的生產和分銷系統,我們承諾為客戶提供最具競爭力的價格。

Q4: 產品品質好嗎?

是的。所有產品在批量生產前都會進行測試,我們將在發貨前檢查物理性能、形狀和公差,以確保產品合格。

請隨時與我聯絡:

艾米

銷售經理

株洲創德硬質合金有限公司

215, building 1, International Students Pioneer Park,

株洲市天元區泰山路。

電子郵件:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/微信/Skype : 0086 13786352688

相關產品

給我們發郵件