ẸSORI

PE WA

Factory Custom yg6 yg8 Wear Resistance Hard Alloy Sandblasting Nozzles Tungsten Carbide Nozzle Manufacturer

Imeeli:

Imeeli:

Factory Custom yg6 yg8 Wear Resistance Hard Alloy Sandblasting Nozzles Tungsten Carbide Nozzle Manufacturer

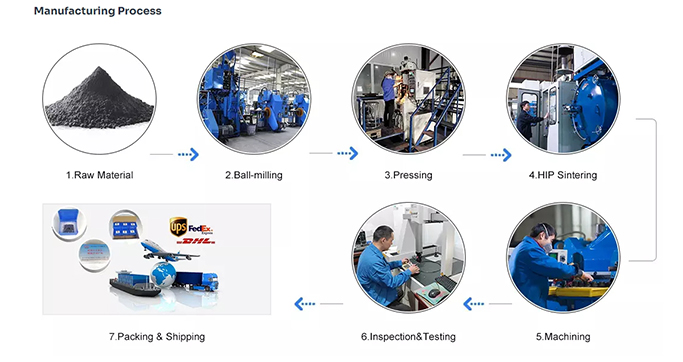

The cemented carbide nozzle is made of precision machinery and cemented carbide material (superhard alloy). Carbide nozzle is formed by hot pressing sintering of hot straight hole and mound hole. Due to its hardness, low density and excellent wear and corrosion resistance, cemented carbide nozzles have been widely used in sand blasting and shot blasting equipment, ensuring that the products can be used in the best air and abrasive for a long time

.

2. Various kinds of grades are available based on customer's application.

3. we have professional advanced production line and inspection equipment to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

Grade : YG6/YG8/YG6X/G10/K10

Standard Dimension

| NO. | OD(mm) | ID(mm) can be adjusted | Length(mm) can be adjusted |

| 1 | 4 | 0.3-2 | 4.0-12 |

| 2 | 5 | 0.3-2 | 4.0-12 |

| 3 | 6 | 0.3-2 | 6.0-20 |

| 4 | 8 | 2.0-3.0 | 10-85 |

| 5 | 10 | 1.0-3.0 | 10-85 |

| 6 | 12 | 2.0-4.0 | 10-85 |

| 7 | 14 | 2.0-5.0 | 25-85 |

| 8 | 15 | 2.0-6.0 | 25-85 |

| 9 | 18 | 3.0-7.0 | 25-85 |

| 10 | 20 | 5.0-10.0 | 25-100 |

| 11 | 21 | 5.0-10.0 | 25-100 |

| 12 | 22 | 5.0-12.0 | 25-100 |

| 13 | 24 | 5.0-14.0 | 25-100 |

| 14 | 26 | 5.0-14.0 | 25-100 |

| 15 | 28 | 5.0-14.0 | 25-100 |

| 16 | 29 | 8.0-20.0 | 25-100 |

| 17 | 30 | 12-20.0 | 25-100 |

Why Choose Tungsten Carbide Nozzle

When Inevitable to rough handling and media used for cutting abrasives (glass beads, steel shots, minerals, or cinder), carbide nozzles have the advantages of being more economical and longer service life. Traditionally, tungsten carbide is the best choice for the material of the nozzles.

They are widely used in surface treatment, sandblasting, painting, electronics, chemical processes and other industries with different applications such as wire straightening, wire guides, and other aspects.

FAQ:

Q1: Ṣe o jẹ Ile-iṣẹ tabi ile-iṣẹ iṣowo?

A jẹ Factory pẹlu awọn ọdun 12 ti iriri iṣelọpọ.

Q2: Nibo ni ile-iṣẹ rẹ wa?

A wa ni ilu Zhuzhou, agbegbe Hunan nibiti ipilẹ ti tungsten carbide wa.

Q3: Ṣe idiyele Idije?

A ni ile-iṣẹ ti ara wa. Ṣeun si iṣelọpọ agbara ati eto pinpin, a ṣe ileri lati fun awọn alabara wa ni idiyele ifigagbaga julọ.

Q4: Ṣe awọn ọja jẹ Didara to gaju?

Bẹẹni. Gbogbo awọn ọja yoo ni idanwo ṣaaju iṣelọpọ olopobobo, ati pe a yoo ṣayẹwo awọn ohun-ini ti ara, apẹrẹ ati ifarada fun aridaju awọn ọja ti o pe ṣaaju gbigbe.

Lero lati kan si mi:

Aimee

Alabojuto nkan tita

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Agbegbe, Zhuzhou Ilu.

Imeeli:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688

Awọn ọja ti o jọmọ

FI mail ranṣẹ si wa

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Fi kun215, ile 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

FI mail ranṣẹ si wa

Ẹ̀TỌ́ Àwòkọ́ṣe :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy