IINDIDI

QHAGAMSHELANA NATHI

YG15 G30 Tungsten carbide plates blocks non standard for diaper electrics molds

I-imeyile:

I-imeyile:

YG15 G30 Tungsten carbide plates blocks non standard for diaper electrics molds

Product Description

Tungsten Carbide Plates YG11 YG15 YG18 Hip sintering Features

1. 100% virgin tungsten carbide materials.

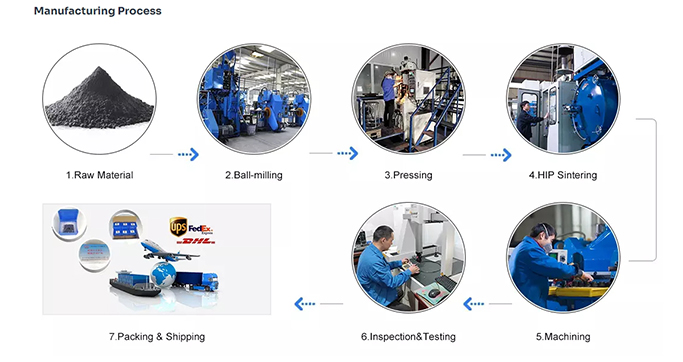

2. HIP Sintering and ground surface.

3. Composition: WC+Co, WC+TiC+TaC+Co.

4. ISO9001:2015 vertified professional manufacturer over 12 years.

5. OEM and ODM are accepted as well.

Tungsten carbide plates that are especially suitable for protecting surfaces against abrasive and erosive wear. The plates are made of tungsten carbide and can be adjusted with different chemical compositions to the requirements of each specific application

1. To make punching dies: It can be applied to the production of high-speed die and multi-station progressive die for punching copper, aluminum, stainless steel, cold-rolled sheet, hardware, standard parts, upper and lower punches, etc.

2. To make wear-resistant tools.

3. To make high temperature resistant parts, wear parts and anti-shielding parts. such as the guide rail of the machine tool and the anti-theft reinforcement board of the ATM.

4. To make corrosion-resistant parts for the chemical industry.

5. To used as radiation and corrosion resistant materials for medical equipment.

Carbide plate is a highly efficient and green material, which features qualities of stainless steel: Corrosion resistance,oxidation resistance, wear resistance, bonding proof and acid-base resistance; And ensures its good strength, toughness, bending and stretching, impact resistance.

Grade of Wear parts hard alloy widia cemented tungsten carbide board block bar plates

Grade | Properties & Applications | Approx Grades in China | |||

Density | T.R.S | Hardness | |||

g/cm3 | MPα | HRA | |||

CD6A | 14.9 | 2000 | 92.5 | Fine grain alloy, good wear resistance. It is suitable for manufacturing forming cutter, wear-resistant parts etc. | YG6A |

CD8 | 14.7 | 2800 | 89.8 | High bending strength, wear resistance lower than YM6A, suitable for manufacturing forming cutter, wear-resistant parts etc. | YG8 |

CD11 | 14.4 | 2900 | 88.5 | High bending strength, wear resistance lower than YM6A, suitable for manufacturing forming cutter, wear-resistant parts etc. | YG11 |

CD15 | 14 | 3000 | 87 | Suitable for manufacturing punching dies, wear-resistant parts. | YG15 |

CD20 | 13.5 | 2800 | 85.5 | High bending strength, suitable for manufacturing progressive dies and other punching dies. | YG20 |

CD13X | 14.2 | 3200 | 90.0 | High bending strength, suitable for manufacturing progressive dies and other punching dies. | YG13X |

CD2T | 14.25 | 2500 | 92.0 | Fine grain alloy, with high wear resistance, bending strength, bonding resistance and thermal strength. It is suitable for machining refractory alloys, stainless steel, high manganese steel, etc. | YS2T |

Application of Wear parts hard alloy widia cemented tungsten carbide board block bar plates

1.Applied on heat-resistant parts, wear-resistance parts, anti-shielding parts, anti-corrosion parts.

2.For making progressive press tools and progressive dies of high velocity ram machine.

3.For making connectors in electron industry, IC industry and semiconductor.

4.Used for armature, stator, LED lead frame, EI silicon steel sheet and punching mould for hardware and standard parts.

Dimension (mm) and shape

Length (100-500mm) *Width (100-500mm)*Thickness(1-20mm) , we will produce blanks (HIP sintering )

Tolerance : blank (L:+-1 , W:+-0.5, T :+-0.1/+/0.5 ) ,Ground :L/W/T : +/0.01, Ra 0.1

This shape is nonstandard ,we can produce according to your drawings .

FAQ:

Q1: Ngaba uyiFactory okanye inkampani yokurhweba?

SiyiFactory kunye neminyaka eyi-12 yamava emveliso.

Q2: Uphi umzi-mveliso wakho?

Sifumaneka kwisixeko saseZhuzhou, kwiphondo laseHunan apho isiseko se- tungsten carbide .

I-Q3: Ngaba ixabiso liyakhuphisana?

SineFactory eyethu. Siyabulela kwimveliso eyomeleleyo kunye nenkqubo yokuhambisa, sithembisa ukunika abathengi bethu elona xabiso likhuphisanayo.

I-Q4: Ngaba iimveliso zikumgangatho ophezulu?

Ewe. Zonke iimveliso ziya kuvavanywa phambi kokuveliswa kobuninzi, kwaye siya kujonga iipropati ezibonakalayo, imilo kunye nokunyamezela ukuqinisekisa iimveliso ezifanelekileyo ngaphambi kokuthunyelwa.

Nceda uqhagamshelane nam:

Aimee

Umlawuli wentengiso

Zhuzhou Chuangde Cemented Carbide Co

215, building 1, International Students Pioneer Park,

I-TaishanRoad, iSithili se-Tianyuan, iSixeko sase-Zhuzhou .

I-imeyile:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

IIMVELISO EZINXULUMENEYO

SITHUMELE imeyile

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Yongeza215, isakhiwo 1, Abafundi beZizwe ngezizwe Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SITHUMELE imeyile

ILUNGELO LOBUKHUNI :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy