13

2024

-

11

Likheo tsa Carbide Rotary Burr: Sesebelisoa se Felletseng sa ho sebetsa ka tšepe

Likheo tsa Carbide rotary burr ke lisebelisoa tsa bohlokoa ts'ebetsong ea tšepe, tse sebelisoang haholo ho pholletsa le tlhahiso ea mechini, sefofane, tlhahiso ea likoloi, le tse ling. Sengoliloeng sena se shebisisa litšobotsi, mefuta, lits'ebetso tsa tlhahiso, le ts'ebeliso ea indasteri ea likheo tsa carbide rotary burr.

I. Litšobotsi tsa Carbide Rotary Burr Blanks

Likheo tsa Carbide rotary burr li tumme ka boima ba tsona bo phahameng le ho se mamelle. Haholo-holo li na le liphofo tsa boholo ba micron tsa li-carbide tsa tšepe tse refractory (joalo ka tungsten carbide WC le titanium carbide TiC), e kopantsoeng le cobalt (Co) kapa nickel (Ni), molybdenum (Mo) ka libopi tsa vacuum kapa libopi tsa phokotso ea hydrogen. Lihlahisoa tsena tsa metallurgical tsa phofo li ka khaola litšepe tse fapa-fapaneng (ho kenyeletsoa le tšepe e thata) le lisebelisoa tse sa kang tsa tšepe (joaloka 'mabole le jade) ka tlase ho HRC70, hangata li nkela mabili a manyenyane a silang a kenngoa ka shank ntle le tšilafalo ea lerōle.

II. Mefuta ea Carbide Rotary Burr Blanks

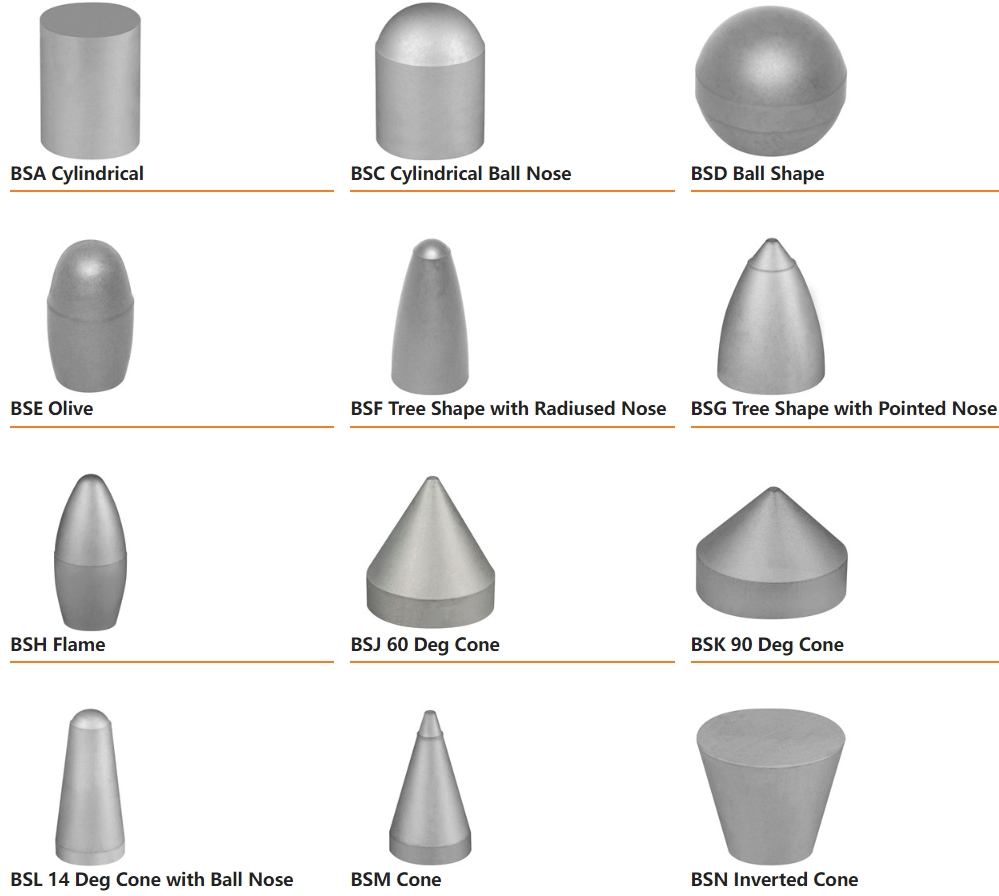

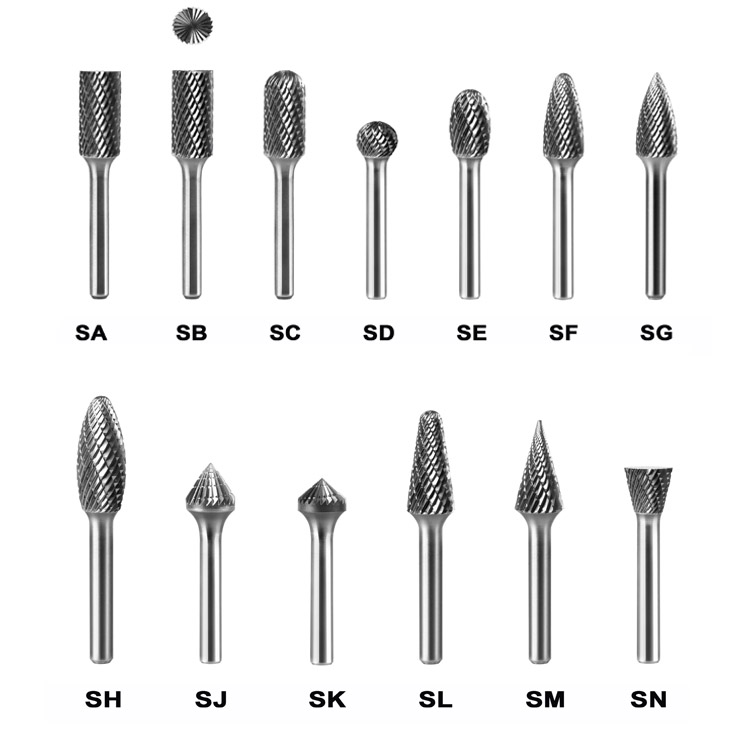

Likheo tsa Carbide rotary burr li tla ka libopeho tse fapaneng ho fana ka litlhoko tse fapaneng tsa ts'ebetso. Libopeho tse tloaelehileng haholo li kenyelletsa cylindrical, spherical, le sebopeho sa lelakabe, hangata li hlalosoa ka litlhaku tse kang A, B, C ka lapeng, le khutsufatso e kang ZYA, KUD, RBF machabeng. Ntle le moo, ho ipapisitsoe le ts'ebeliso, likheo tsa carbide rotary burr li arotsoe ka mefuta e thata le ea ho qeta, ka lisebelisoa ho tloha ho tšepe ea lebelo le holimo, tšepe ea alloy, ho ea ho carbide.

III. Mokhoa oa ho hlahisa Carbide Rotary Burr Blanks

Ho hlahisa likheo tsa carbide rotary burr ho kenyelletsa ts'ebetso e rarahaneng, ho kenyelletsa:

Ho Sila ka Metsi: Ho kopanya lisebelisoa tse tala tsa alloy ho latela diresepe le ho li sila ka thepa ea ho sila e metsi. Linako tsa ho sila li fapana ho tloha ho lihora tse 24 ho isa ho tse 96 ho latela recipe.

Tlhahlobo ea Sampling: Nakong ea ho sila ka metsi, lisebelisoa tse tala li hlahlojoa ka lisampole. Ka mor'a ho omisa, ho kopanya sekhomaretsi, ho omisa hape, ho hlahloba, ho hatella, ho sintering, le liteko tse ngata tse kang boima ba 'mele, boima, matla a ho phunyeha, matla a qobelloang, boikemisetso ba carbon, magnetic saturation le microscopic cross-sectional observation, carbide e tiisetsoa hore e kopane. matšoao a ts'ebetso e hlokoang ke mophato oa eona.

Ho omisa: Ka mor'a ho sila le ho na pula, lisebelisoa tse tala li kena ka se omisang mouoane bakeng sa ho omisoa, hangata se nka lihora tse 2 ho isa ho tse 5.

IV. Likopo tsa Carbide Rotary Burr Blanks

Likheo tsa Carbide rotary burr li na le ts'ebeliso e pharaletseng ea ho sebetsa ka tšepe. Li sebelisetsoa ho etsa machining a nepahetseng a liphaephe tsa hlobo ea tšepe, ho phethela likarolo tse kaholimo, le lits'ebetso tse ling tse fapaneng, ho kenyeletsoa ho hloekisa liphaephe. Ka lebaka la boima ba bona bo phahameng le ho hanyetsa ho apara, likheo tsa carbide rotary burr li ka finyella litlhoko tsa ho sebetsana le litšepe tse sa tšoaneng tse kang tšepe e entsoeng ka tšepe, tšepe e entsoeng ka tšepe, koporo, boronse, li-alloys tse thehiloeng ho nickel le tse se nang tšepe tse kang marble.

V. Tšebeliso le Tlhokomelo

Ha u sebelisa likheo tsa carbide rotary burr, nahana ka tse latelang:

Polokeho: Apara likhalase tse sireletsang le liatlana ho thibela litšepe tsa tšepe le mokelikeli o sehang hore o se ke oa qhoma ka mahlong le matsohong. Boloka sebaka sa mosebetsi se hloekile ebile se le makhethe ho qoba likotsi.

Tshebetso e nepahetseng: Khetha lebelo le nepahetseng la ho potoloha le sekhahla sa phepelo ho netefatsa hore rotary burr e sebetsa hantle. Kenya sebaka sa li-rotary burrs hang-hang ho qoba ho eketsa boima ba mochini le litšenyehelo.

Tlhokomelo: Hloekisa li-chips tsa tšepe khafetsa le mokelikeli o sehang ho lelefatsa bophelo ba rotary burr.

VI. Mekhoa ea 'Maraka le Tsoelo-pele

Lilemong tsa morao tjena, indasteri ea carbide ea Chaena e hotse ka potlako, ka boholo ba mmaraka bo ntseng bo hola. E le karolo ea bohlokoa ea lihlahisoa tsa carbide, tlhoko ea likheo tsa carbide rotary burr le eona ea eketseha. Ka khothaletso e matla ea naha ea ts'ireletso ea tikoloho le matla a hloekileng, indasteri ea carbide e mocheng oa menyetla e mecha ea ntlafatso. Nakong e tlang, likheo tsa carbide rotary burr li tla fumana lits'ebetso libakeng tse ngata, tse fanang ka tšehetso e betere bakeng sa tlhahiso ea indasteri.

Ka kakaretso, likheo tsa carbide rotary burr li phetha karolo ea bohlokoa indastering ea tšepe ka lebaka la litšobotsi tsa tsona tse ikhethang le mefuta e mengata ea likopo. Khetho e nepahetseng le tšebeliso e ka ntlafatsa haholo boleng le katleho ea ts'ebetso ea tšepe, e fana ka tšehetso e ntle bakeng sa tlhahiso ea indasteri.

TS'OANELO LITABA

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Eketsa215, mohaho oa 1, Phaka ea Bopula-maliboho ba Liithuti tsa Machaba, Tsela ea Taishan, Setereke sa Tianyuan, Motse oa Zhuzhou

RE THUSOE MOSE

MOPIRI :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy