13

2024

-

11

Carbide Rotary Burr Bannaanka: Qalabka Waxkabadan ee Biraha

Carbide rotary burr maran waa aaladaha lagama maarmaanka u ah shaqada birta, oo si weyn looga faa'iidaysto soo saarista mishiinada, hawada hawada, wax soo saarka baabuurta, iyo in ka badan. Maqaalkani waxa uu si qoto dheer u galay sifooyinka, noocyada, hababka wax soo saarka, iyo codsiyada warshadaha ee carbide rotary burr bannaan.

I. Tilmaamaha Carbide Rotary Burr Bannanka

Carbide rotary burr maran waxay caan ku yihiin adayggooda sare iyo xidhashada caabbinta. Waxay ugu horrayn ka kooban yihiin budo cabbirkoodu yar yahay oo kaarbide bir ah oo refractory ah (sida tungsten carbide WC iyo titanium carbide TiC), oo ku xidhan cobalt (Co) ama nikkel (Ni), molybdenum (Mo) foornooyinka faakuumka ama foornooyinka hydrogen dhimista. Badeecadahan budada ah ee birta ah waxay gooyn karaan biraha kala duwan (ay ku jiraan birta adag) iyo walxaha aan birta ahayn (sida marmar iyo jaad) ee ka hooseeya HRC70, inta badan waxay beddelaan giraangiraha yaryar ee shiida ee shank ku rakiban iyada oo aan wasakhayn boodhka.

II. Noocyada Carbide Rotary Burr Bannaanka

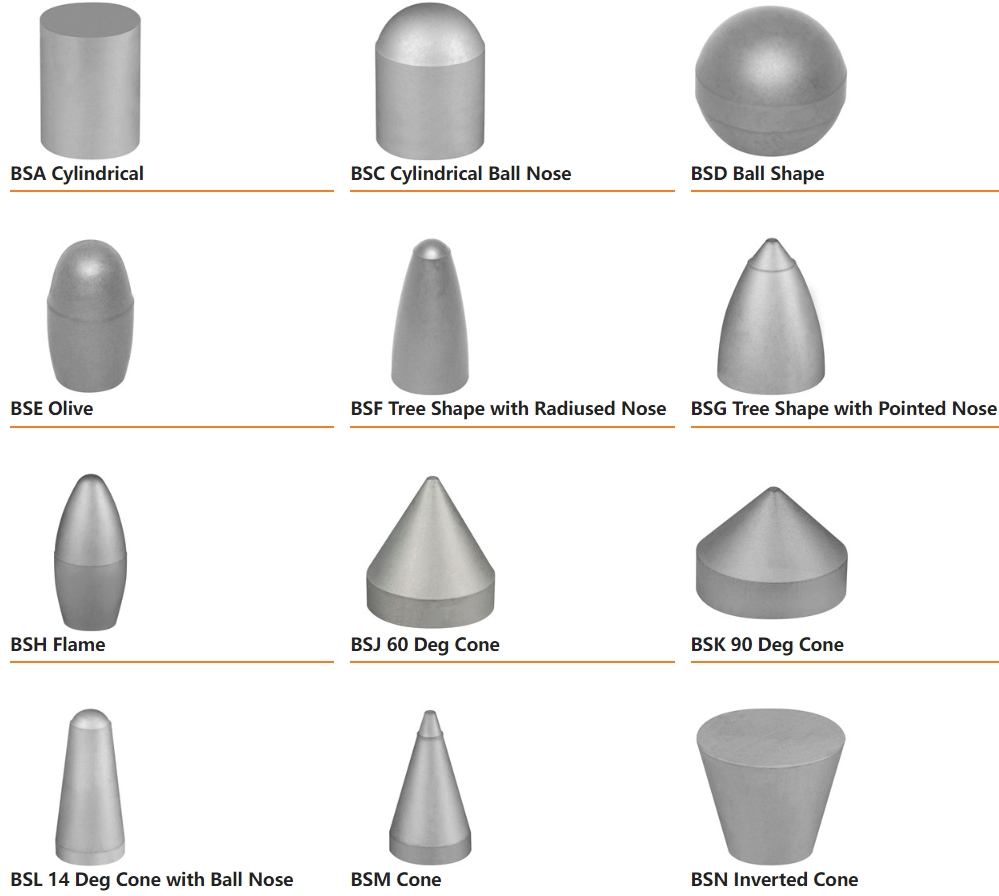

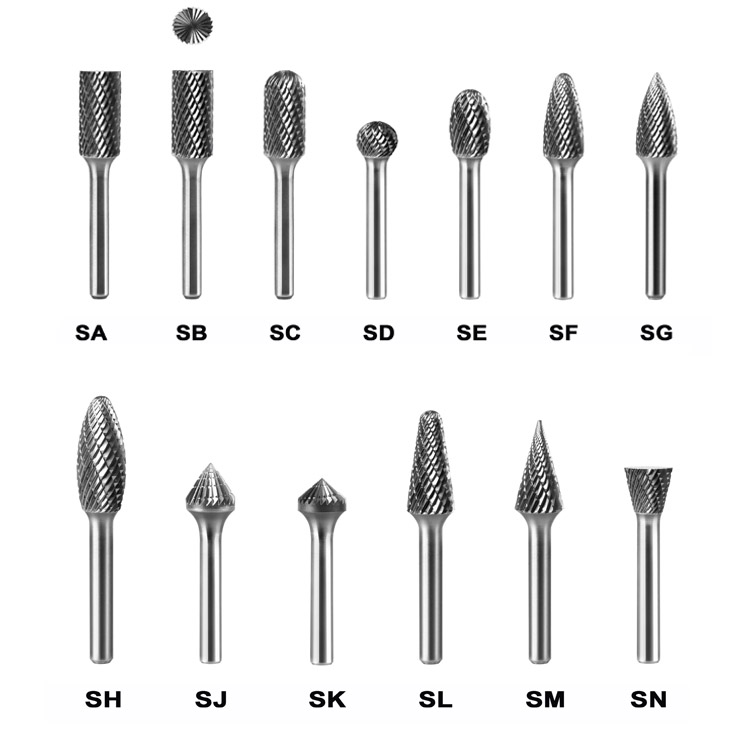

Carbide rotary burr maran waxay ku yimaadaan qaabab kala duwan si ay u daboolaan baahiyaha habaynta ee kala duwan. Qaababka ugu caansan waxaa ka mid ah cylindrical, spherical, iyo flame, oo badanaa lagu tilmaamo xarfaha A, B, C gudaha, iyo soo gaabinta sida ZYA, KUD, RBF caalami ahaan. Intaa waxaa dheer, iyadoo lagu saleynayo isticmaalka, carbide rotary burr maran waxaa loo kala saaray noocyo qallafsan iyo dhammayn, oo leh agabyo u dhexeeya birta-xawaaraha sare leh, birta alloy, iyo karbide.

III. Habka Soo saarida ee Carbide Rotary Burr Bannanka

Soo saarista carbide rotary burr bannaan waxay ku lug leedahay hannaan adag, oo ay ku jiraan:

Shiidi qoyanIsku qas walxaha cayriin ee daawaha sida waafaqsan cuntada iyo ku shiidi qalabka wax lagu shiido qoyan. Waqtiyada wax la shiidi karo way kala duwan yihiin 24 ilaa 96 saacadood iyadoo ku xidhan habka loo kariyo.

Kormeerka Muunada: Inta lagu jiro shiididda qoyan, alaabta ceeriin waxay maraan baaritaan muunad. Ka dib marka la qalajiyo, isku darka xabagta, qalajinta mar kale, baadhista, riixida, sintering, iyo tijaabooyin badan sida cufnaanta, adkaanta, xoogga dillaaca transverse, xoogga qasabka, go'aaminta kaarboonka, saturation magnetka, iyo indho-indheynta iskutallaabyada microscopic, carbide waa la hubiyaa inuu la kulmo tilmaamayaasha waxqabadka looga baahan yahay darajadiisa.

Qalajinta: Ka dib marka la shiido qoyan iyo roobab, alaabta ceeriin waxay galaan qalajiyaha uumiga si ay u engejiyaan, caadi ahaan soconaya 2 ilaa 5 saacadood.

IV. Codsiyada Carbide Rotary Burr Bannanka

Carbide rotary burr maran waxay leeyihiin codsiyo badan xagga biraha. Waxaa loo isticmaalaa mashiinada saxda ah ee godadka caaryada birta ah, dhamaystirka qaybaha dusha sare, iyo hawlo kale oo kala duwan, oo ay ku jiraan nadiifinta dhuumaha. Sababo la xiriira adkeysigooda sare iyo xirashada iska caabin, carbide rotary burr banaan buuxin kartaa shuruudaha processing ee biraha kala duwan sida bir tuuray, birta shubay, birta sita, naxaas, bronze, Alloys ku salaysan nikkel, iyo non-birta sida marmar.

V. Isticmaalka iyo Dayactirka

Markaad isticmaalayso carbide rotary burr maran, tixgeli kuwan soo socda:

BadbaadadaXiro muraayadaha difaaca iyo galoofyada si aad uga hortagto jajabyada birta ah iyo jarista dareeraha inay ku firdhiyaan indhaha iyo gacmaha. Goobta shaqada ka dhig mid nadiif ah oo nadiif ah si aad uga fogaato shilalka.

Hawlgalka saxda ah: Dooro xawaaraha wareega saxda ah iyo heerka quudinta si aad u hubiso in burka wareega uu si sax ah u shaqeeyo. Si degdeg ah u beddel burooyinka wareega ee caajiska ah si aad uga fogaato korodhka culeyska iyo kharashyada mashiinka.

Dayactirka: Si joogto ah u nadiifi jajabyada birta ah iyo jarista dareeraha si loo kordhiyo cimriga burka wareega

VI. Isbeddellada Suuqa iyo Horumarka

Sanadihii la soo dhaafay, warshadaha karbidhida ee Shiinaha ayaa si xawli ah u koray, iyada oo baaxadda suuqa ay sii korodhay. Iyada oo ah qayb muhiim ah oo ka mid ah alaabada karbidhida, baahida loo qabo carbide rotary burr meelaha banaan ayaa sidoo kale sii kordhaya. Iyada oo waddanku si xoog leh kor ugu qaaday ilaalinta deegaanka iyo tamarta nadiifka ah, warshadaha carbide waxay diyaar u yihiin fursado horumarineed oo cusub. Mustaqbalka, carbide rotary burr burr bannaan waxay ka heli doontaa codsiyada meelo badan, siinta taageero wanaagsan oo wax soo saarka warshadaha.

Marka la soo koobo, meelaha bannaan ee carbide rotary burr waxay door muhiim ah ka ciyaaraan warshadaha birta ee birta sababtoo ah sifooyinkooda gaarka ah iyo codsiyo badan oo kala duwan. Xulashada saxda ah iyo isticmaalka ayaa si weyn u wanaajin kara tayada iyo hufnaanta farsamaynta birta, iyagoo siinaya taageero wanaagsan oo wax soo saarka warshadaha.

WARAR LA XIRIIRA

Hal qayb oo ka mid ah Zhuzhou Chuangde Cemented Carbide Co., Ltd

Ku dar215, dhismaha 1, Ardayda Caalamiga ah ee Pioneer Park, Taishan Road, Degmada Tianyuan, Magaalada Zhuzhou

NOO SOO DIR

Xuquuqda daabacaada :Hal qayb oo ka mid ah Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy