VAEGA

FAAFESOOTAI MATOU

Factory Custom yg6 yg8 Wear Resistance Hard Alloy Sandblasting Nozzles Tungsten Carbide Nozzle Manufacturer - 副本

imeli:

imeli:

Factory Custom yg6 yg8 Wear Resistance Hard Alloy Sandblasting Nozzles Tungsten Carbide Nozzle Manufacturer - 副本

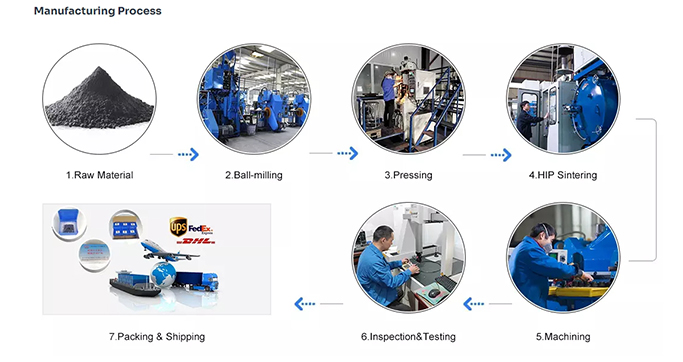

The cemented carbide nozzle is made of precision machinery and cemented carbide material (superhard alloy). Carbide nozzle is formed by hot pressing sintering of hot straight hole and mound hole. Due to its hardness, low density and excellent wear and corrosion resistance, cemented carbide nozzles have been widely used in sand blasting and shot blasting equipment, ensuring that the products can be used in the best air and abrasive for a long time

.

1. 100% virgin raw materials.

2. Various kinds of grades are available based on customer's application.

3. we have professional advanced production line and inspection equipment to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

Grade : YG6/YG8/YG6X/G10/K10

Standard Dimension

| NO. | OD(mm) | ID(mm) can be adjusted | Length(mm) can be adjusted |

| 1 | 4 | 0.3-2 | 4.0-12 |

| 2 | 5 | 0.3-2 | 4.0-12 |

| 3 | 6 | 0.3-2 | 6.0-20 |

| 4 | 8 | 2.0-3.0 | 10-85 |

| 5 | 10 | 1.0-3.0 | 10-85 |

| 6 | 12 | 2.0-4.0 | 10-85 |

| 7 | 14 | 2.0-5.0 | 25-85 |

| 8 | 15 | 2.0-6.0 | 25-85 |

| 9 | 18 | 3.0-7.0 | 25-85 |

| 10 | 20 | 5.0-10.0 | 25-100 |

| 11 | 21 | 5.0-10.0 | 25-100 |

| 12 | 22 | 5.0-12.0 | 25-100 |

| 13 | 24 | 5.0-14.0 | 25-100 |

| 14 | 26 | 5.0-14.0 | 25-100 |

| 15 | 28 | 5.0-14.0 | 25-100 |

| 16 | 29 | 8.0-20.0 | 25-100 |

| 17 | 30 | 12-20.0 | 25-100 |

Why Choose Tungsten Carbide Nozzle

When Inevitable to rough handling and media used for cutting abrasives (glass beads, steel shots, minerals, or cinder), carbide nozzles have the advantages of being more economical and longer service life. Traditionally, tungsten carbide is the best choice for the material of the nozzles.

They are widely used in surface treatment, sandblasting, painting, electronics, chemical processes and other industries with different applications such as wire straightening, wire guides, and other aspects.

FAQ:

Q1: O oe Falegaosi po'o kamupani fefa'ataua'iga?

O matou o Factory ma 12 tausaga o le gaosiga o le poto masani.

Q2: O fea oi ai lau falegaosimea?

O loʻo matou i totonu o le taulaga o Zhuzhou, le itumalo o Hunan o loʻo i ai le faʻavae o le tungsten carbide.

Q3: E fa'atauva le tau?

E iai a matou lava Falegaosimea. Faʻafetai i le gaosiga malosi ma le tufatufaina atu o faiga, matou te folafola atu e ofoina atu ia matou tagata faʻatau le tau sili ona tauva.

Q4: O oloa maualuga maualuga?

Ioe. O oloa uma o le a faʻataʻitaʻiina aʻo leʻi faia le tele o gaosiga, ma o le a matou siakiina meatotino faʻapitoa, foliga ma le faʻapalepale mo le faʻamautinoaina o oloa faʻamaonia aʻo leʻi lafoina.

Lagona le saoloto e fa'afeso'ota'i a'u:

Aimee

Pule fa'atau

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

imeli:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

O MEA E FAI AI

AUMAI MAI IA TE MILI

Zhuzhou Chuangde Sima Carbide Co., Ltd

Faaopoopo215, fale 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

AUMAI MAI IA TE MILI

PULE :Zhuzhou Chuangde Sima Carbide Co., Ltd

Sitemap

XML

Privacy policy