KATEGÓRIE

KONTAKTUJ NÁS

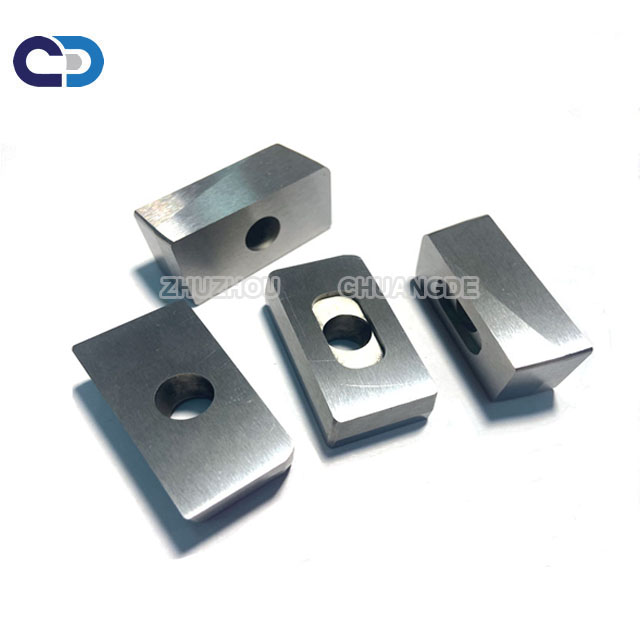

G20 K20 K30 YG20 cemented carbide dies molds nonstandard as wear risistance parts

Email:

Email:

G20 K20 K30 YG20 cemented carbide dies molds nonstandard as wear risistance parts

Description of G20 K20 K30 YG20 cemented carbide dies molds nonstandard as wear risistance parts

1) Extension of die life and stability of life

By controlling the particle size distribution of WC, can make the plastic deformation and reduce the load of thecemented carbide to improve the compressive strength and fracture toughness, delaying the occurrence and propagation of cracks of the mould process, long service life, and has a very high consistency.

2)Bite and adhesion decreased considerably

High temperature single crystal WC was used to strengthen the binding of crystalline structure and effectively strengthen the cobalt phase, thus effectively inhibiting the cracking of the material.

3)The corrosion resistance and electrical resistance of the cemented carbide are improved

Because of the strengthening of the cobalt phase, the corrosion resistance of the cemented carbide is greatly improved, so that the cemented carbide is suitable for discharge machining.

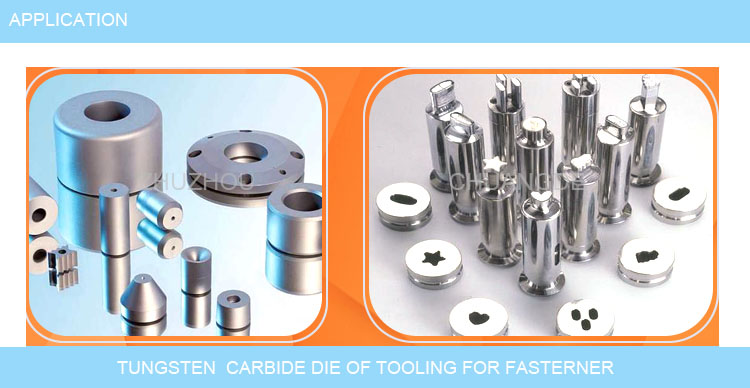

Applications of G20 K20 K30 YG20 cemented carbide dies molds nonstandard as wear risistance parts

Suitable working industry regarding as your reference :

1. The oil industry

2. Industrial equipment

3. Precision instruments

4. Chemical equipment

The service life of the cemented carbide mold is more than ten times or even dozens of times that of the steel mold. The cemented carbide mold has high hardness, high strength, corrosion resistance, high temperature resistance and small expansion coefficient. Common cemented carbide molds: cold heading die, cold stamping die, wire drawing die, hexagonal die, spiral die, etc

| Grade | Density g/cm3 | Hardness HRA | T.R.S Mpa | Performance&application recommended |

| YG11 | 14.4 | 88.5 | 2420 | Forming or stamping dies for metal powders and nonmetal powders |

| YG15 | 14 | 87 | 3000 | It is suitable for drawing steel tubes and rods under high compression ratio,manufacturing upsetting,punching and stamping tools under large stress |

| YG20 | 13.5 | 85.5 | 2800 | It is suitable for manufacturing punching dies for watch parts,leaf spring of musical instrument,battery jars,small sized steel balls,screws,screw caps,etc |

| YG16C | 13.9 | 85 | 2750 | It is suitable for impact-resistant forging dies |

| YG18C | 13.7 | 84 | 2800 | It is suitable for impact-resistant forging dies,hot-forging dies and finishing rollers |

| YG20C | 13.5 | 83 | 2850 | It is suitable for wear resistant or impact resistant dies |

| YG22C | 13.3 | 82 | 2900 | It is suitable for nut forming dies and high impact-resistant dies |

| YG25C | 13.1 | 81.5 | 3000 | It is suitable for stainless screw dies and semifinishing rollers |

| Other grades and sizes can be offered as per customers' requirement | ||||

Our Advantages :

1.Strong Mould R&D team. We support product customization as per specific requirements, ensure high working efficiency with good product quality.

2.Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

3.Strong R&D team. Professional engineers serve for clients, recommend products and grades as per your applications. We also offer after-sale service.

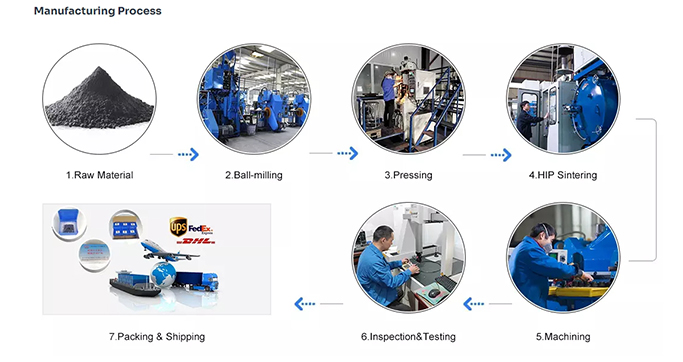

4.100% raw material for production.6. Hip sintered, reliable hardness, durable wear resistance

5. Various sizes, carbide grade and full types available

6. Competitive price with on-time delivery

7. Customized product as per drawing and small order accepted,professional and in-time technical support .

FAQ:

Q1: Ste továreň alebo obchodná spoločnosť?

Sme továreň s 12-ročnými výrobnými skúsenosťami.

Q2: Kde sa nachádza vaša továreň?

Nachádzame sa v meste Zhuzhou, provincia Hunan, kde je základňa karbidu volfrámu .

Q3: Je cena konkurencieschopná?

Máme vlastnú továreň. Vďaka silnému výrobnému a distribučnému systému sľubujeme, že našim zákazníkom ponúkneme najkonkurencieschopnejšiu cenu.

Q4: Sú produkty vysokej kvality?

áno. Všetky produkty budú testované pred hromadnou výrobou a pred odoslaním skontrolujeme fyzikálne vlastnosti, tvar a toleranciu na zabezpečenie kvalifikovaných produktov.

Neváhajte ma kontaktovať:

Aimee

Manažér predaja

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Obvod Tianyuan, Mesto Zhuzhou.

Email:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688

SÚVISIACE PRODUKTY

POŠLITE NÁM POŠTU

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Pridať215, budova 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

POŠLITE NÁM POŠTU

AUTORSKÉ PRÁVA :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy