CATEGORIES

CONTACT US

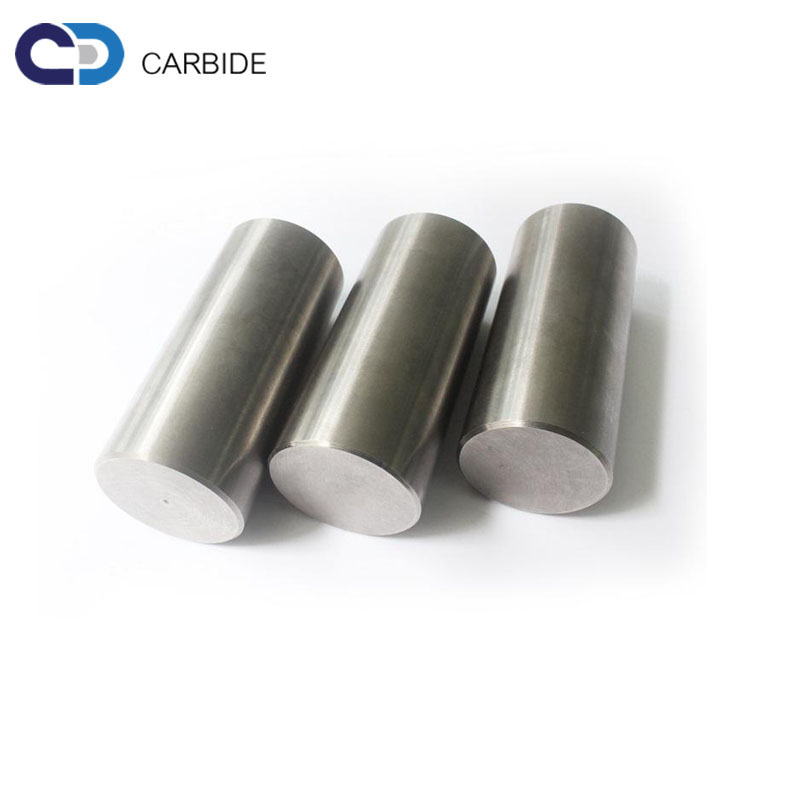

Cemented carbide Tungsten Heavy alloy rod product with high density and good performance

Email:

Email:

Cemented carbide Tungsten Heavy alloy rod product with high density and good performance

Cemented carbide Tungsten Heavy alloy rod product with high density and good performance

Product Description:

High-density tungsten alloy is an alloy material composed of tungsten as the base material (with tungsten content of 85%~99%) and a small amount of nickel (Ni), copper (Cu), iron (Fe), cobalt (Co), molybdenum (Mo), chromium (Cr) and other metal binders, also known as high-density tungsten alloy or heavy alloy [1]. The density of high specific gravity tungsten alloy can reach 16.5~19.0g/cm3.

2. Main Applications:

The most commonly used products are W-Ni-Cu and W-Ni-Fe series. This material has significant characteristics in physical properties such as density, strength, hardness, ductility, conductivity/thermal conductivity, and is widely used in defense industry, aerospace industry, medical industry, electrical industry and other industries.

3. Our Grades:

It is mainly divided into two series: W-Ni-Fe (with magnetism) and W-Ni-Cu (without magnetism). It adopts isostatic pressure molding technology and extrusion, molding and injection molding technology to produce tungsten based high specific gravity products of various types and specifications.

Chemical composition and physical and mechanical properties of tungsten based high specific gravity alloy:

| Grade | Nominal tungsten content | Density | Hardness | Tensile strength | Elongation |

|---|---|---|---|---|---|

| W(%) | g/cm3 | Rockwell C | MPa | % | |

| 1 | 90 | 16.85-17.25 | 24-32 | 700-1200(600-800) | 20-33(4-8) |

| 2 | 92.5 | 17.15-17.85 | 25-30 | 700-1400(500-600) | 15-25(3-5) |

| 3 | 95 | 17.75-18.35 | 25-35 | 700-1200 | 8-15 |

| 4 | 97 | 18.25-18.85 | 30-35 | 600-1000 | 8-14 |

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy