CATEGORIES

CONTACT US

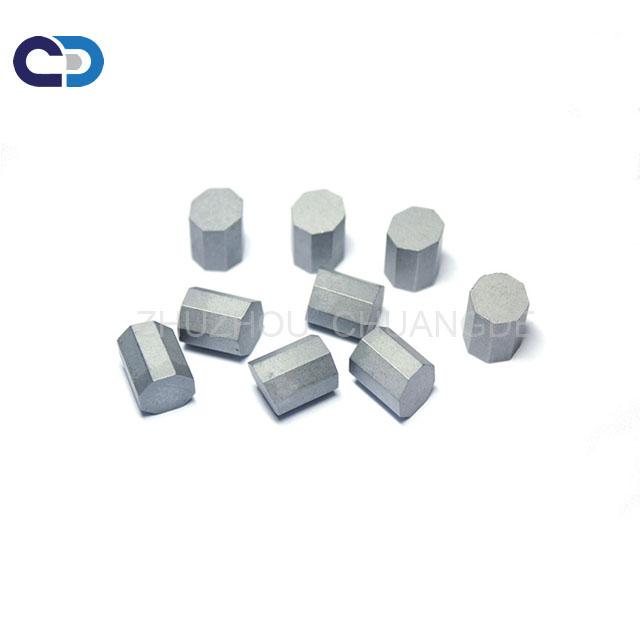

Manufacturer Cemented Carbide Octagons buttons inserts tips

Email:

Email:

Manufacturer Cemented Carbide Octagons buttons inserts tips

Description of Manufacturer Cemented Carbide Octagons buttons inserts tips

Description of Manufacturer Cemented Carbide Octagons buttons inserts tips

Product Name | Carbide Octagonal Tips | Material | 100% Raw Material |

Color | Gray | Shape | Customized |

Size | Customer's Request | Certification | ISO9001 |

Usage | Mining tools for drilling | Type | Tungsten Carbide |

Chemical composition | WC+CO | Tolerance | Customer's Request |

Standard | GB | MOQ | 1 kg |

Lead time | 5-15 days | Price | USD 30-56Per KG |

Working life | Long Work Time | Port | Beijing,Shanghai,Shenzhen |

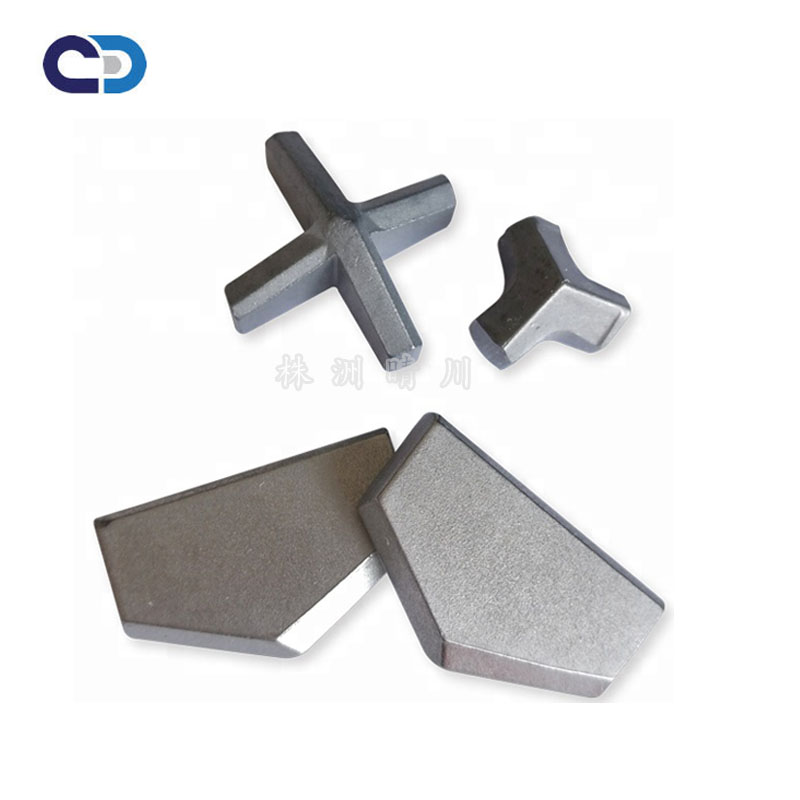

Application of Manufacturer Cemented Carbide Octagons buttons inserts tips

1.Tungsten carbide bits with octagonal tips are normally used for coring in softer rock formations, overburden drilling, and cleaning of drill holes. Octagonal Cemented Carbide Drilling Inserts Mining Tips are normally used for coring in softer rock formations, overburden drilling, and cleaning of drill holes

2.Octagonal cemented carbide is also known as T-type cemented carbide, alloy for water wells, and is also used for formation core drills.

3.Zhuzhou Chuangde Cemented Carbide Co., Ltd. specializes in the production of large octagonal, medium octagonal, and small octagonal .

4.Our grade can meet the needs of various sand and rock formations, continuous toothing during the mining process, and long service life.

Grade of Manufacturer Cemented Carbide Octagons buttons inserts tips

| Grade | Density | T.R.S | Hardness | Performance & application recommended | Approx Grades in China |

| g/cm3 | MPα | HRA | |||

| CD6 | 14.9 | 2100 | 90 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, usd in geological prospecting, coal mining and oil well boring. | YG6 |

| CD6.1 | 14.7 | 2400 | 89.5 | For coring crowns, electric coal drill bits, coal cutting picks, cone drill bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. | YG8 |

| CD06H | 15 | 3000 | 90.5 | Good strength and less wear resistance, for bits of rotary hammer rock drills and heavy rock drills, for hard and very hard rocks. | YK05, KK06H |

| CD15 | 14 | 2500 | 87.5 | Good strength and less wear resistance, for bits of rotary hammer rock drills and heavy rock drills, for hard and very hard rocks. | YG15 |

| CD10 | 14.7 | 2450 | 88.5 | Mostly used as the buttons of small and mediumsized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. | YG8C |

| CD15 | 14.7 | 2450 | 87.8 | Suitable to strips, conical buttons for rotary,percussion-resistant, geological prospecting,buttons, cut soft and medium hard formations. | YK15/YG9C |

| CD20 | 14.4 | 2550 | 87 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. | YK20/YG10C |

| CD25 | 14.5 | 2600 | 87.5 | Primarily for the buttons and inserts of rotary percussion bits to cut medium hard and very hard formations. | YK25 |

| CD30 | 14.4 | 2600 | 87 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. | YG11C |

| CD40 | 14.2 | 2650 | 86.5 | Predominatly for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and vey hard formations. | YK40/YG13C |

| CD50 | 14 | 2700 | 86.5 | For oil cone drill bits, for medium soft and medium -hard rocks. | YG15C |

Other grades may be offered by customers' requirements.

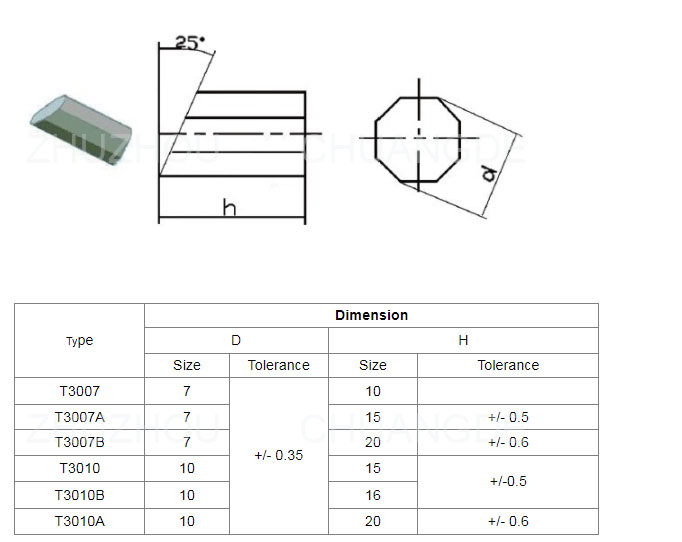

DIMENSION (MM) of Manufacturer Cemented Carbide Octagons buttons inserts tips

Advantage

1.Strong production capacity. We own mature production technology, process, various TPA press, large tonnage of hydraulic press and HIP furnace, ensuring pressing quality and sintering capacity achieving 1 ton per time. We can guarantee uniformity and stability of mass production.

2.Strong R&D team. Professional engineers serve for clients, recommending product and grades as per your applications. They also offer best after-sale service.

3.Strong Mould R&D team. They support customization of products as per requirements, and ensure high working efficiency and product quality.

4.Successful cooperate case: We cooperate with clients in domestic and abroad, and get good feedback from them.

FAQ:

Q1 : Are you Factory or trading company ?

We are Factory with 12 years of production experience.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base of tungsten carbide .

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products High Quality?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Feel free to contact me :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Email: info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy