24

2024

-

10

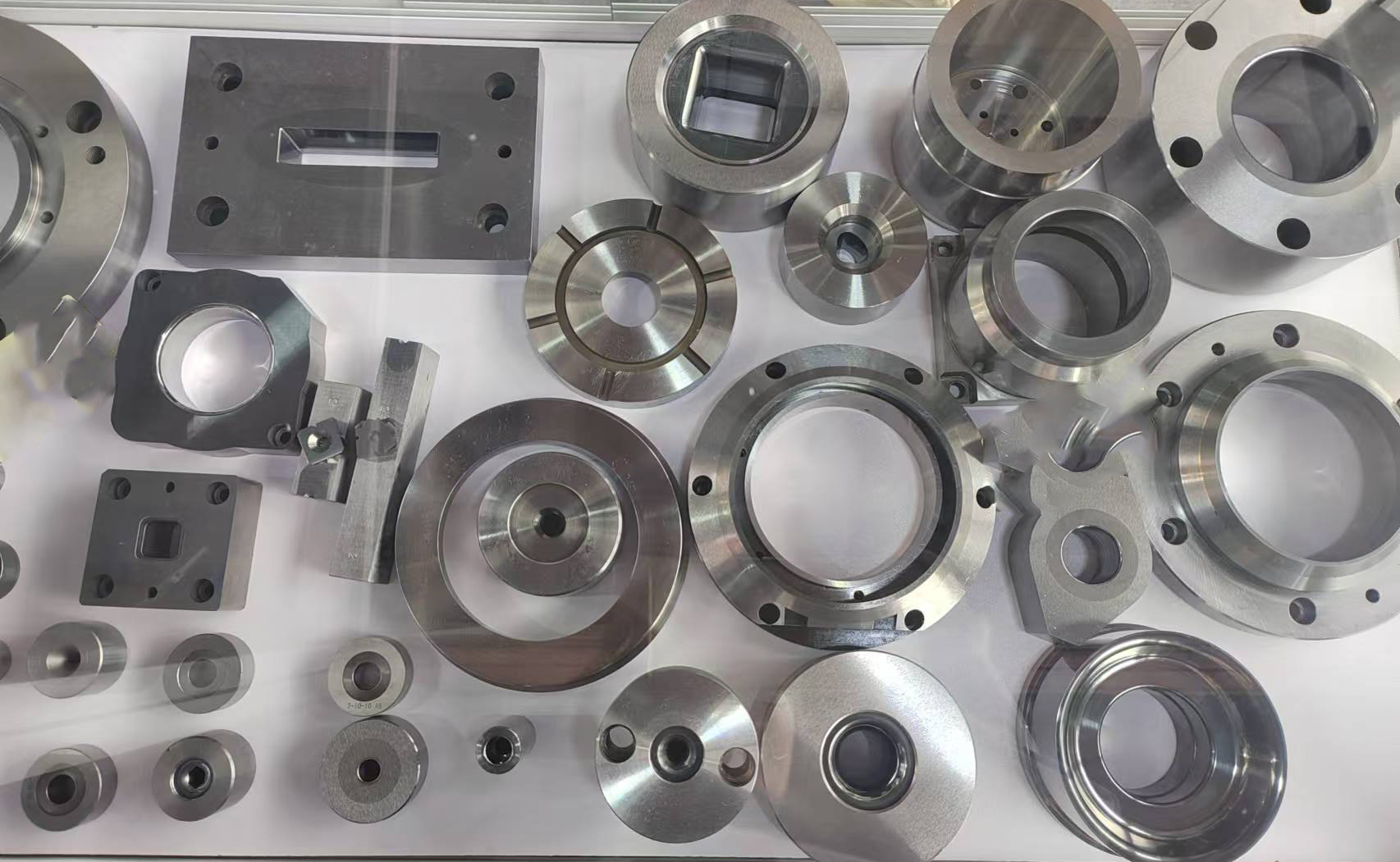

Tungsten Carbide Dies: A Sharp Tool in the Manufacturing Industry

Tungsten carbide dies, as vital tools in modern manufacturing, are widely used across various production sectors due to their high hardness, corrosion resistance, high-temperature resistance, and low coefficient of thermal expansion. This article delves into the characteristics, application fields, manufacturing techniques, and market trends of tungsten carbide dies.

I. Characteristics of Tungsten Carbide Dies

Tungsten carbide dies are typically made from tungsten, cobalt, and other metal powders through high-temperature sintering, possessing a series of excellent properties. Firstly, they have extremely high hardness and can maintain stable hardness even at high temperatures, making the dies resistant to wear during use and thus extending their service life. Secondly, tungsten carbide dies exhibit good corrosion resistance and high-temperature resistance, enabling them to maintain stable mechanical strength and precision in harsh working environments. Furthermore, the low coefficient of thermal expansion of tungsten carbide helps reduce size changes caused by temperature variations, ensuring product quality.

Tungsten carbide dies play a crucial role in the manufacturing industry. Below are the common material grades and their corresponding application fields:

Common Material Grades

YG Series

YG3: Suitable for drawing non-ferrous metals and non-metal materials.

YG6: Commonly used for drawing large-diameter steel wires and steel strands.

YG6X: Compared to YG6, it has higher wear resistance and is suitable for more complex drawing tasks.

YG8: A major grade for drawing dies, suitable for drawing various specifications of steel wires.

YG15, YG20, YG20C, YG25: These grades are typically used for dies requiring high hardness and wear resistance, such as cold heading dies and cold punching dies.

HU Series

HU20, HU222: These grades have specific physical and chemical properties, suitable for specific die manufacturing needs.

HWN1

HWN1 (non-magnetic alloy die): Suitable for dies used in the production of magnetic materials, avoiding magnetization of the die in a magnetic environment, which could affect product quality.

Other Grades

YC20C, CT35, YJT30, MO15: These grades are commonly used for cold heading, cold punching, and shaping dies.

YSN Series (such as YSN20, YSN25, YSN30, etc.): Used for non-magnetic alloy dies in the production of magnetic materials.

TMF: A grade of steel-bonded non-magnetic die, also suitable for the production of magnetic materials.

Application Fields

Drawing Dies

Tungsten carbide drawing dies account for a significant portion of tungsten carbide dies and are widely used in the drawing of metal materials such as steel wires and steel strands.

Cold Heading, Cold Punching, and Shaping Dies

These dies are used in cold heading, cold punching, and shaping processes, such as the manufacture of fasteners like bolts and nuts.

Dies for Magnetic Material Production

Non-magnetic alloy dies are suitable for the production of magnetic materials, avoiding interference from the die on the magnetic materials.

Other Fields

Tungsten carbide dies are also widely used in mechanical processing, metallurgy, oil drilling, mining tools, electronic communications, construction, and other fields for the manufacture of various cutting tools, wear-resistant components, and more.

In summary, there are numerous common material grades of tungsten carbide dies, each with its specific application fields and advantages. When selecting tungsten carbide dies, it is essential to choose the appropriate material grade based on specific usage requirements and working environments to ensure the performance and service life of the die.

RELATED NEWS

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy