02

2024

-

04

What is tungsten carbide

Cemented carbide is an alloy material made through powder metallurgy technology . It is mainly composed of hard compounds of refractory metals and bonding metals.

The main components of cemented carbide include refractory carbide powders such as tungsten carbide and titanium carbide, as well as metal powders used as binders, such as cobalt and nickel. This material is known for its high hardness, wear resistance, strength and toughness, heat resistance and corrosion resistance, especially at high temperatures while maintaining these properties. The hardness and wear resistance of cemented carbide are basically unchanged at 500°C, and it can still maintain a high hardness at 1000°C. Therefore, it is widely used in manufacturing cutting tools, drilling tools, measuring tools, cold work molds and various wear-resistant parts.

The main components of cemented carbide include refractory carbide powders such as tungsten carbide and titanium carbide, as well as metal powders used as binders, such as cobalt and nickel. This material is known for its high hardness, wear resistance, strength and toughness, heat resistance and corrosion resistance, especially at high temperatures while maintaining these properties. The hardness and wear resistance of cemented carbide are basically unchanged at 500°C, and it can still maintain a high hardness at 1000°C. Therefore, it is widely used in manufacturing cutting tools, drilling tools, measuring tools, cold work molds and various wear-resistant parts.

It has the following basic properties:

1. High hardness: The hardness of cemented carbide is usually much higher than that of ordinary metal materials, which makes it effectively resistant to wear and cutting.( Normally between 80HRA-94HRA)

2. High strength: Carbide has high strength, can withstand greater pressure and load, and is not easy to deform or break. (Normally TRS between 2000-3200 Mpa )

3. Wear resistance: Due to its high hardness, carbide has excellent wear resistance and is suitable for applications that require long-term wear resistance.

4. Corrosion resistance: Carbide has good resistance to most corrosive media and can maintain its performance in harsh environments.

5. High temperature stability: It can maintain its physical and chemical properties at higher temperatures and is not easy to soften or deform.

6. Good electrical and thermal conductivity: Some cemented carbide has good electrical and thermal conductivity, making it useful in the fields of electronics and thermal management.

These properties make cemented carbide widely used in tool manufacturing, machining, aerospace, petrochemical and other fields. Different types of carbide can be tailored to meet specific performance needs by adjusting composition and manufacturing processes. However, specific performance characteristics may vary depending on the carbide composition, structure and manufacturing process. In practical applications, appropriate carbide materials need to be selected according to specific usage conditions and requirements.

CD carbide is professional in tungsten carbide products such like wear resistance part,mining tools,cutting tools and so on .

RELATED NEWS

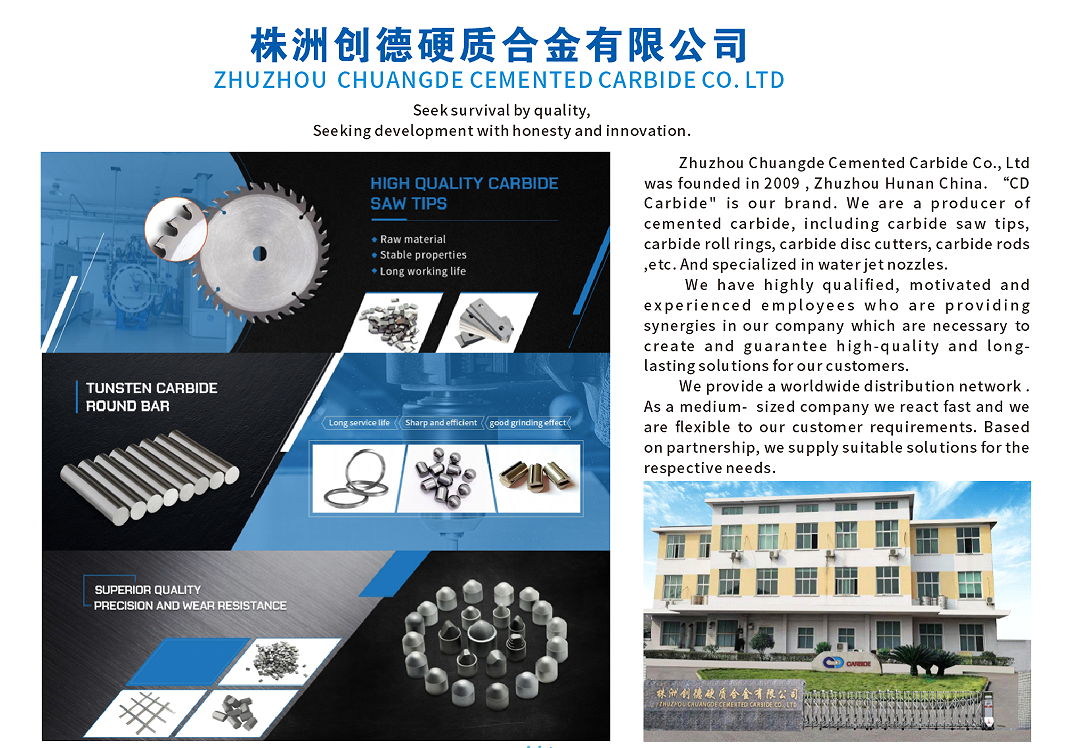

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy