13

2024

-

11

Carbide Rotary Burr Blanks: The Versatile Tool in Metalworking

Carbide rotary burr blanks are essential tools in metalworking, widely utilized across machinery manufacturing, aerospace, automotive production, and more. This article delves into the characteristics, types, production processes, and industrial applications of carbide rotary burr blanks.

I. Characteristics of Carbide Rotary Burr Blanks

Carbide rotary burr blanks are renowned for their high hardness and wear resistance. They primarily consist of micron-sized powders of refractory metal carbides (such as tungsten carbide WC and titanium carbide TiC), bonded with cobalt (Co) or nickel (Ni), molybdenum (Mo) in vacuum furnaces or hydrogen reduction furnaces. These powder metallurgical products can cut through various metals (including hardened steel) and non-metallic materials (like marble and jade) below HRC70, often replacing shank-mounted small grinding wheels without dust pollution.

II. Types of Carbide Rotary Burr Blanks

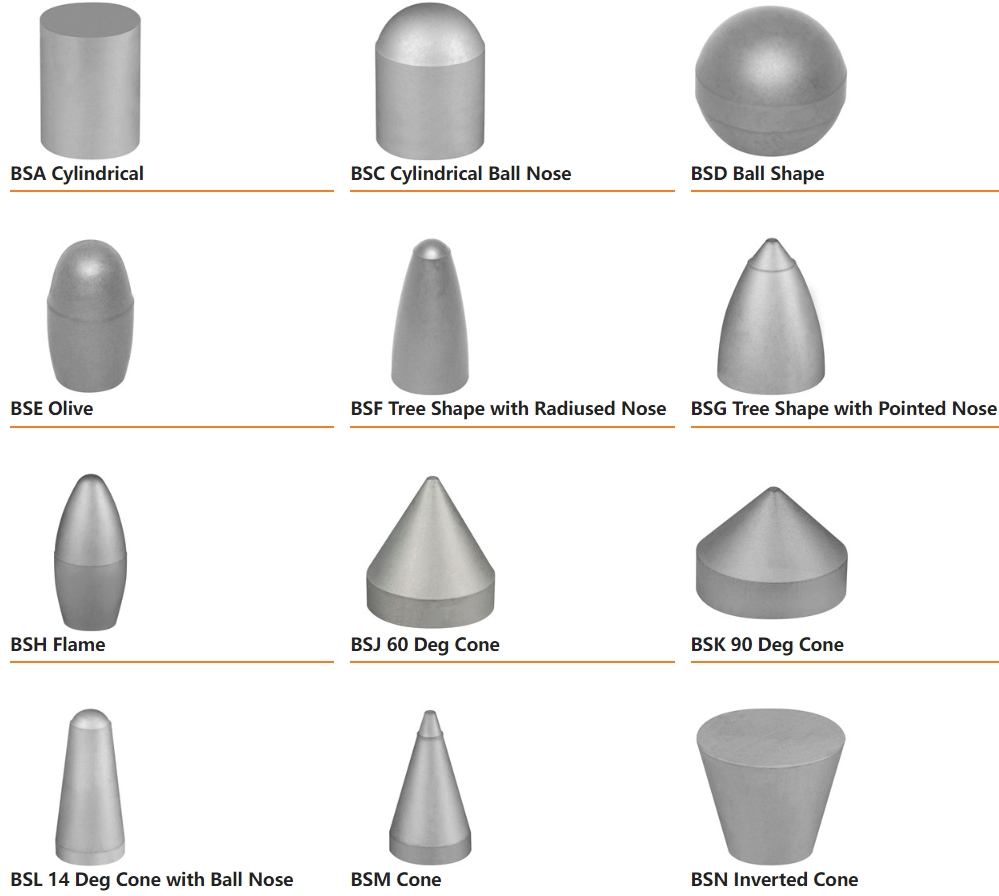

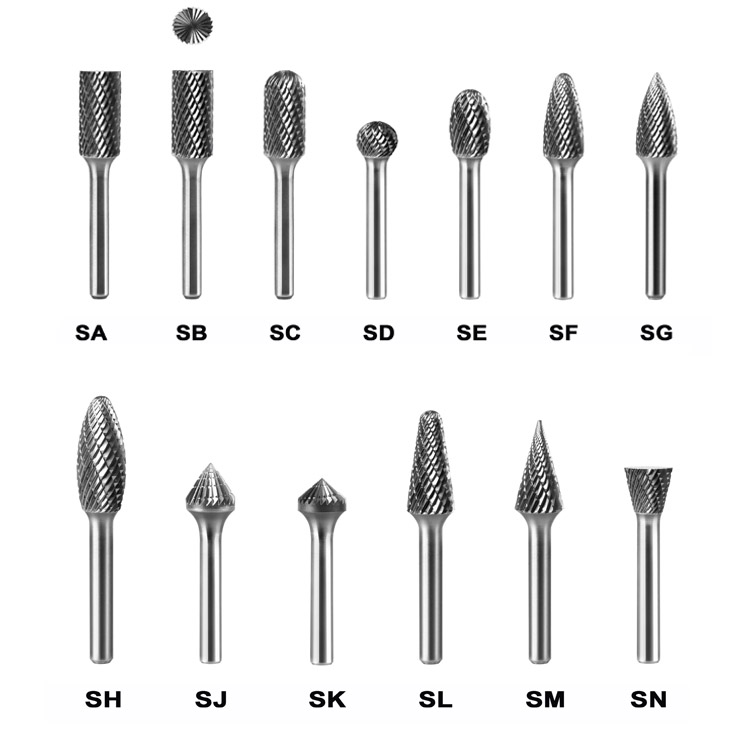

Carbide rotary burr blanks come in various shapes to cater to different processing needs. The most common shapes include cylindrical, spherical, and flame-shaped, often denoted by letters like A, B, C domestically, and abbreviations like ZYA, KUD, RBF internationally. Furthermore, based on usage, carbide rotary burr blanks are categorized into roughing and finishing types, with materials ranging from high-speed steel, alloy steel, to carbide.

III. Production Process of Carbide Rotary Burr Blanks

The production of carbide rotary burr blanks involves a complex process, including:

Wet Grinding: Mixing alloy raw materials according to recipes and grinding them in wet grinding equipment. Grinding times vary from 24 to 96 hours depending on the recipe.

Sampling Inspection: During wet grinding, raw materials undergo sampling inspections. After drying, glue mixing, drying again, screening, pressing, sintering, and multiple tests such as density, hardness, transverse rupture strength, coercive force, carbon determination, magnetic saturation, and microscopic cross-sectional observation, the carbide is ensured to meet the performance indicators required by its grade.

Drying: After wet grinding and precipitation, the raw materials enter a steam dryer for drying, typically lasting from 2 to 5 hours.

IV. Applications of Carbide Rotary Burr Blanks

Carbide rotary burr blanks have extensive applications in metalworking. They are used for precision machining of metal mold cavities, surface finishing of parts, and various other operations, including pipeline cleaning. Due to their high hardness and wear resistance, carbide rotary burr blanks can meet the processing requirements of various metals such as cast iron, cast steel, bearing steel, brass, bronze, nickel-based alloys, and non-metals like marble.

V. Usage and Maintenance

When using carbide rotary burr blanks, consider the following:

Safety: Wear protective glasses and gloves to prevent metal chips and cutting fluid from splashing into eyes and hands. Keep the work area clean and tidy to avoid accidents.

Proper Operation: Select the correct rotational speed and feed rate to ensure the rotary burr functions properly. Replace dull rotary burrs promptly to avoid increasing machine load and costs.

Maintenance: Regularly clean metal chips and cutting fluid to extend the lifespan of the rotary burr.

VI. Market Trends and Development

In recent years, China's carbide industry has grown rapidly, with an expanding market size. As a crucial component of carbide products, the demand for carbide rotary burr blanks is also increasing. With the country's strong promotion of environmental protection and clean energy, the carbide industry is poised for new development opportunities. In the future, carbide rotary burr blanks will find applications in more fields, providing better support for industrial manufacturing.

In summary, carbide rotary burr blanks play a significant role in the metalworking industry due to their unique characteristics and wide range of applications. Proper selection and use can significantly improve the quality and efficiency of metal processing, offering better support for industrial manufacturing.

RELATED NEWS

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy