31

2024

-

10

Carbide Wire Drawing Dies: Precision Guardians in Wire Manufacturing

Carbide Wire Drawing Dies: Precision Guardians in Wire Manufacturing

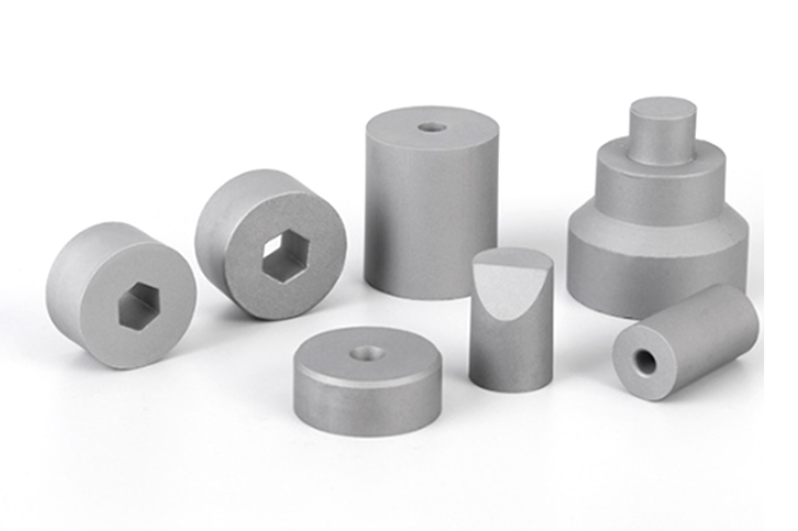

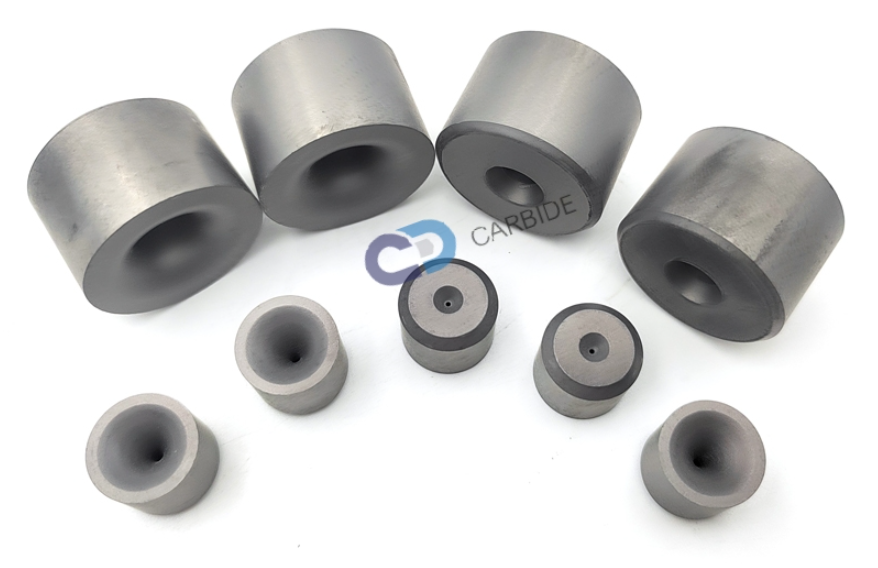

In the wire manufacturing industry, carbide wire drawing dies play a crucial role in enhancing production efficiency and quality, acting as the "precision guardians" on the wire production line, ensuring the smooth and accurate formation of wires.

Features

1. Exceptional Wear Resistance

Carbide wire drawing dies are renowned for their extremely high hardness, which allows them to withstand the intense abrasion that occurs during the wire drawing process. When the wire is pulled through the die, the die's hardness enables it to maintain a smooth inner surface and resist wear for an extended period. This is a significant advantage over traditional die materials, as it not only extends the service life of the die but also reduces the need for frequent replacements due to wear, thereby ensuring the continuous and stable operation of wire production.

2. High Precision Dimensional Control

The precision machining capabilities of carbide materials enable the production of wire drawing dies with extremely high dimensional accuracy. These dies can precisely control the diameter and cross-sectional shape of the wire being drawn, meeting the strict requirements of the modern wire industry for highly accurate wire dimensions. Whether it's for fine wires used in electronics or thicker wires for industrial applications, carbide wire drawing dies can guarantee consistent and precise sizing.

3. Excellent Thermal Conductivity

4. Chemical Stability

In many wire drawing applications, the wire may come into contact with various substances that could potentially cause corrosion or chemical reactions. Carbide wire drawing dies exhibit excellent chemical stability, resisting corrosion and chemical attacks. This ensures that the die remains unaffected by the surrounding environment, maintaining its performance and dimensional accuracy over time. It is particularly beneficial when drawing wires made of special alloys or in environments where chemical contaminants are present.

Grade

YG6X

YG6

Provides a balance of hardness and toughness, versatile for a wide range of wire drawing operations.

YG8

Known for higher toughness, applicable in wire drawing processes with potential impact or more demanding conditions.

YG15

Has increased hardness and strength, ideal for high-quality wire drawing requiring better wear resistance and load-bearing capacity.

YG20

With higher hardness and wear resistance, useful for applications demanding durability and precision, like in electronics or automotive industries.

YG25

Features excellent wear resistance and strength, suitable for more demanding and continuous wire drawing tasks.

YG20C

Has specific properties for particular wire drawing scenarios, perhaps related to chemical composition or performance in specific environments.

YG20D

Similar to YG20C with distinct characteristics optimized for certain applications, such as in wires with specific mechanical properties.

YSN30

Possesses unique properties, applicable in specialized wire drawing operations for meeting specific production requirements or quality standards.

RELATED NEWS

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

SEND US MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy