31

2024

-

10

कार्बाईड वायर रेखांकनाचा मृत्यूः वायर मॅन्युफॅक्चरिंगमधील प्रेसिजन गार्डियन्स

कार्बाईड वायर रेखांकनाचा मृत्यूः वायर मॅन्युफॅक्चरिंगमधील प्रेसिजन गार्डियन्स

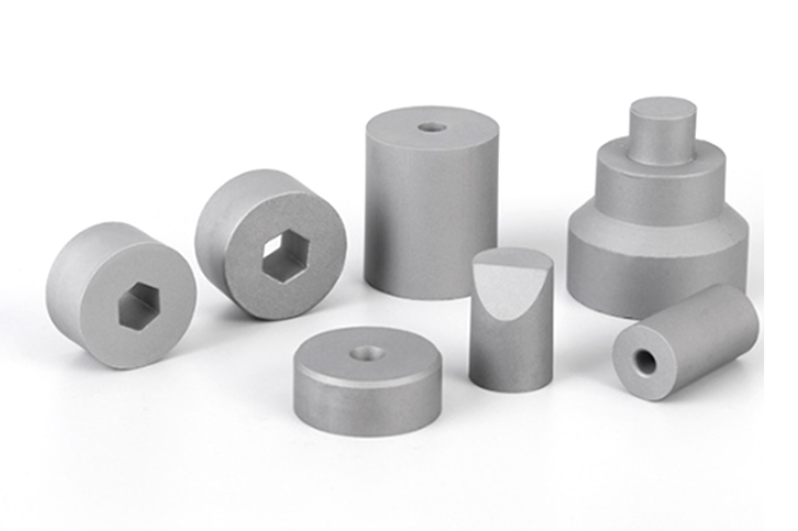

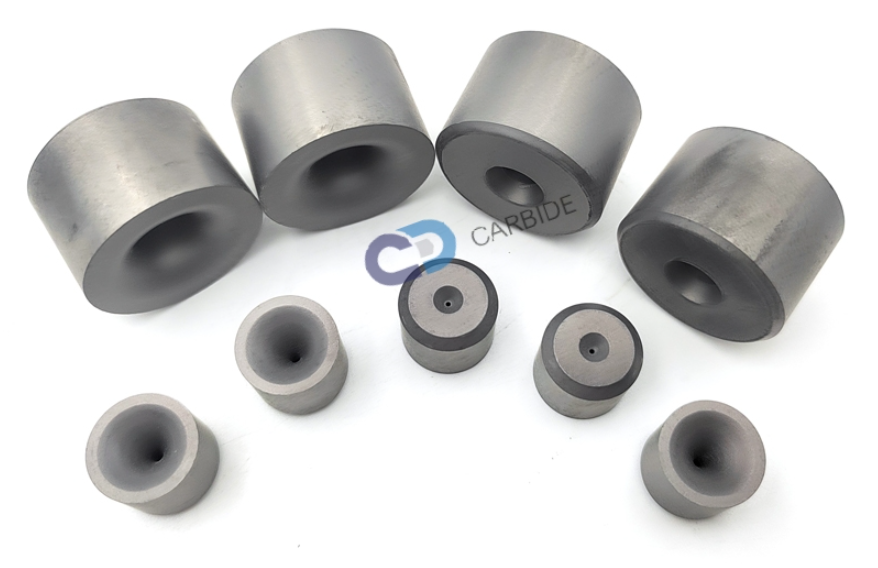

वायर मॅन्युफॅक्चरिंग इंडस्ट्रीमध्ये, कार्बाईड वायर ड्रॉइंग डायज उत्पादन कार्यक्षमता आणि गुणवत्ता वाढविण्यात महत्त्वपूर्ण भूमिका बजावतात, वायर उत्पादन लाइनवर "अचूक संरक्षक" म्हणून काम करतात, वायरची गुळगुळीत आणि अचूक निर्मिती सुनिश्चित करतात.

वैशिष्ट्ये

1. अपवादात्मक पोशाख प्रतिकार

कार्बाईड वायर ड्रॉईंग डायज त्यांच्या अत्यंत कठोरपणासाठी प्रसिद्ध आहेत, ज्यामुळे त्यांना वायर रेखांकन प्रक्रियेदरम्यान होणार्या तीव्र घर्षणाचा प्रतिकार करण्यास अनुमती मिळते. जेव्हा वायर डायमधून खेचले जाते, तेव्हा मरणाची कडकपणा यामुळे एक गुळगुळीत आतील पृष्ठभाग राखण्यास आणि विस्तारित कालावधीसाठी पोशाखांना प्रतिकार करण्यास सक्षम करते. पारंपारिक डाय मटेरियलवर हा एक महत्त्वपूर्ण फायदा आहे, कारण यामुळे केवळ मरच्या सर्व्हिस लाइफचा विस्तार होत नाही तर परिधान केल्यामुळे वारंवार बदलण्याची आवश्यकता देखील कमी होते, ज्यामुळे वायर उत्पादनाचे सतत आणि स्थिर ऑपरेशन सुनिश्चित होते.

2. उच्च सुस्पष्टता आयामी नियंत्रण

कार्बाईड मटेरियलची अचूक मशीनिंग क्षमता वायर रेखांकनाचे उत्पादन अत्यंत उच्च आयामी अचूकतेसह मरणास सक्षम करते. हे मरणास वायरच्या व्यासाचा व क्रॉस-सेक्शनल आकार अचूकपणे नियंत्रित करू शकतो, अत्यंत अचूक वायर परिमाणांसाठी आधुनिक वायर उद्योगाच्या कठोर आवश्यकता पूर्ण करतात. ते इलेक्ट्रॉनिक्समध्ये वापरल्या जाणार्या बारीक तारा किंवा औद्योगिक अनुप्रयोगांसाठी जाड तारा असो, कार्बाइड वायर रेखांकन मरण सुसंगत आणि अचूक आकाराची हमी देऊ शकते.

3. उत्कृष्ट थर्मल चालकता

4. रासायनिक स्थिरता

बर्याच वायर रेखांकन अनुप्रयोगांमध्ये, वायर विविध पदार्थांच्या संपर्कात येऊ शकते ज्यामुळे संभाव्य गंज किंवा रासायनिक प्रतिक्रिया उद्भवू शकतात. कार्बाईड वायर रेखांकन डायस उत्कृष्ट रासायनिक स्थिरता दर्शविते, गंज आणि रासायनिक हल्ल्यांचा प्रतिकार करते. हे सुनिश्चित करते की आसपासच्या वातावरणामुळे मरणे अप्रभावित राहते, कालांतराने त्याची कार्यक्षमता आणि मितीय अचूकता राखते. विशेष मिश्र धातुपासून बनविलेले तारा रेखाटताना किंवा रासायनिक दूषित घटक उपस्थित असलेल्या वातावरणात हे विशेषतः फायदेशीर ठरते.

ग्रेड

YG6X

YG6

वायर रेखांकन ऑपरेशनच्या विस्तृत श्रेणीसाठी अष्टपैलू, कठोरपणा आणि कठोरपणाचे संतुलन प्रदान करते.

YG8

संभाव्य प्रभाव किंवा अधिक मागणी असलेल्या परिस्थितीसह वायर रेखांकन प्रक्रियेमध्ये लागू असलेल्या उच्च खडबडीसाठी ओळखले जाते.

YG15

कडकपणा आणि सामर्थ्य वाढविले आहे, उच्च-गुणवत्तेच्या वायर रेखांकनासाठी आदर्श आहे ज्यासाठी चांगले पोशाख प्रतिकार आणि लोड-बेअरिंग क्षमता आवश्यक आहे.

YG20

इलेक्ट्रॉनिक्स किंवा ऑटोमोटिव्ह उद्योगांप्रमाणेच टिकाऊपणा आणि सुस्पष्टतेची मागणी करणार्या अनुप्रयोगांसाठी उच्च कठोरता आणि पोशाख प्रतिकार सह.

YG25

अधिक मागणी आणि सतत वायर रेखांकन कार्यांसाठी योग्य, उत्कृष्ट पोशाख प्रतिकार आणि सामर्थ्य वैशिष्ट्ये.

YG20C

विशिष्ट वायर रेखांकन परिस्थितीसाठी विशिष्ट गुणधर्म आहेत, कदाचित विशिष्ट वातावरणात रासायनिक रचना किंवा कामगिरीशी संबंधित.

YG20D

विशिष्ट अनुप्रयोगांसाठी ऑप्टिमाइझ केलेल्या वेगळ्या वैशिष्ट्यांसह वायजी 20 सी प्रमाणेच, जसे की विशिष्ट यांत्रिक गुणधर्मांसह तारांमध्ये.

YSN30

विशिष्ट उत्पादन आवश्यकता किंवा दर्जेदार मानकांची पूर्तता करण्यासाठी विशेष वायर ड्रॉईंग ऑपरेशन्समध्ये लागू असलेल्या अद्वितीय गुणधर्म आहेत.

झुझो चुआंगडे सिमेंटेड कार्बाइड कं, लि

जोडा215, बिल्डिंग 1, इंटरनॅशनल स्टुडंट्स पायनियर पार्क, तैशान रोड, टियानयुआन डिस्ट्रिक्ट, झुझू सिटी

आम्हाला मेल पाठवा

कॉपीराइट :झुझो चुआंगडे सिमेंटेड कार्बाइड कं, लि

Sitemap

XML

Privacy policy