KATEGORI

KONTAK KAMI

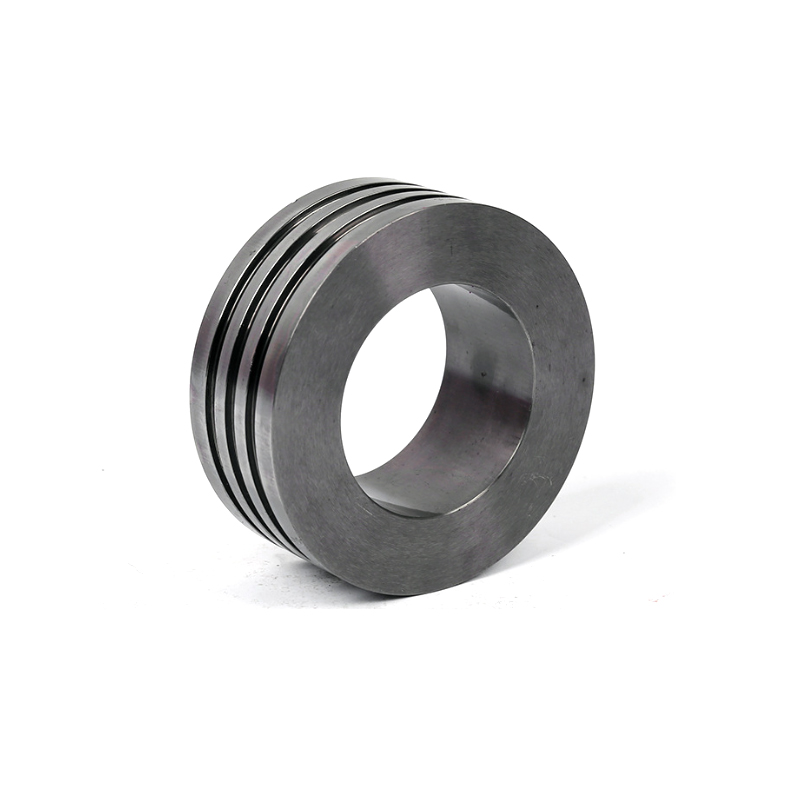

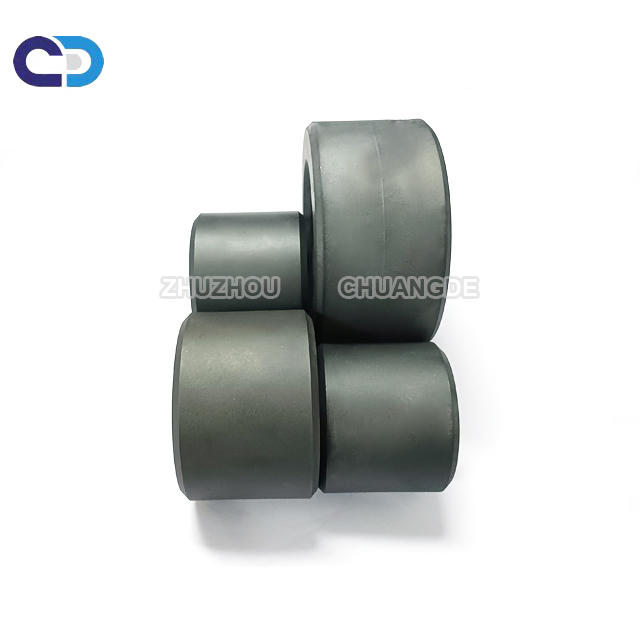

YG15 YGH30 tungsten carbide rolls for rolling mill

Email:

Email:

YG15 YGH30 tungsten carbide rolls for rolling mill

Good wear resistance customized cemented carbide rolls tungsten roller rings

1.Our rolls include oval reducing(RO),round reducing(RT),forming(FO)profiling(PR),sizing(CA).Other types are also available as per your requirements.

2.The rolling volume reaches 800-1500 tons one time, which is 20-50times higher than that of ordinary tool steel.

3.It can be used repeatedly by grinding, which greatly reduces the cost and significantly improves the benefit and efficiency.

Name: Tungsten carbide wire rolls

Material : Tungsten carbide, hard metal, hard alloy,tungsten steel

Composition :Tungsten carbide – TC: 80-92%, Binder – Ni+Co+Cr: 8-20%

Density: 14.0-14.8g/cm3

Hardness: HRA87-92

Features,Advantages: Wear resistant, corrosion resistant, impact resistant

Size Ranges: Outter Dia:800mm, Inner Dia≤700mm, Thickness≤400mm

Roll Types : FO,RO,RT,CA,PR

Applications(Hot Roll) Aluminium and copper wire rod reduction rollers

Applications(Cold Roll )Sizing, Forming reducing and profiling rolls are made of tungsten carbide or steel and are used to produce smooth or ribbed wire for the construction reinforcement field.

Tungsten carbide is a kind of hard alloy, the main components is tungsten carbide and cobalt, the hardness can reach 89~95HRA, with a series of excellent properties such as high hardness, high wear resistance, high strength, high toughness, high heat resistance and high corrosion resistance.

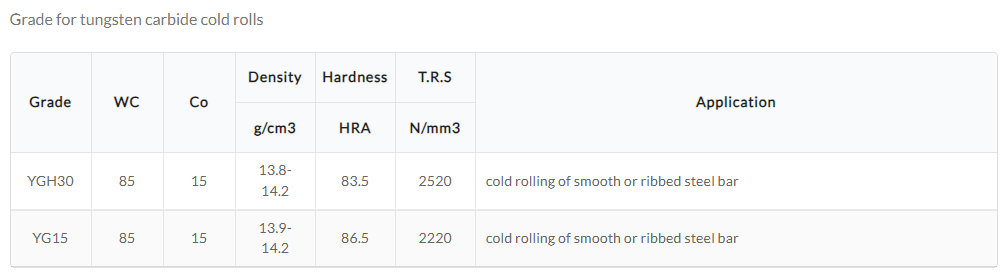

Grade and Size

Grade & Mechaical Properities

Nickel Grade Chart

Grade | Binder(Wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

YN6 | 6 | 14.7 | 89.5 | 1460 |

YN6X | 6 | 14.8 | 90.5 | 1400 |

YN6A | 6 | 14.8 | 91.0 | 1480 |

YN8 | 8 | 14.6 | 88.5 | 1710 |

Cobolt Grade Chart

Grade | Binder(Wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

YG6 | 6 | 14.8 | 90 | 2400 |

YG6X | 6 | 14.9 | 91 | 2300 |

YG6A | 6 | 14.9 | 92 | 2000 |

YG8 | 8 | 14.7 | 89.5 | 2800 |

YG12 | 12 | 14.2 | 88 | 2900 |

YG15 | 15 | 14.0 | 87 | 3000 |

YG20 | 20 | 13.5 | 85.5 | 2850 |

| No. | Outer diameter (mm) | Inner diameter (mm) | Height (mm) |

| 1 | 70 | 60 | 12 |

| 2 | 80 | 70 | 12 |

| 3 | 90 | 82 | 12 |

| 4 | 90 | 85 | 8 |

| 5 | 95 | 90 | 5.5 |

| 6 | 100 | 90 | 12 |

| 7 | 110 | 100 | 12 |

| 8 | 120 | 110 | 12 |

| 9 | 130 | 120 | 12 |

| 10 | 135 | 130 | 5.5 |

| 11 | 165 | 155 | 16 |

| 12 | 150 | 140 | 15 |

| 13 | Other customized size is also available | ||

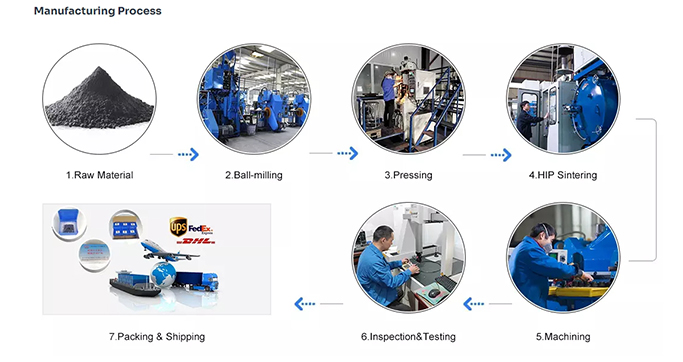

How to make tungsten carbide rolls

powder milling → formula according to grade→ wet grinding → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain a mixture → granulating → pressing → forming → Sintering →preforms→rough machining by flat grinding→non-destructive ultrasonic flaw detection →finishing machining by flat grinding→internal grinding →external grinding→chamfering→notching machining→laser marking→inspection →packing → Storage

FAQ:

Q1: Apa sampeyan Pabrik utawa perusahaan dagang?

Kita Pabrik karo 12 taun pengalaman produksi.

Q2: Where is pabrik Panjenengan?

Kita dumunung ing kutha Zhuzhou, provinsi Hunan sing basis saka tungsten karbida.

Q3: Apa regane Kompetitif?

Kita duwe Pabrik dhewe. Thanks kanggo sistem produksi lan distribusi sing kuwat, kita janji bakal menehi pelanggan rega sing paling kompetitif.

Q4: Apa produk High Quality?

ya wis. Kabeh produk bakal dites sadurunge produksi akeh, lan kita bakal mriksa sifat fisik, wangun lan toleransi kanggo mesthekake produk qualified sadurunge dikirim.

Bebas bae kanggo hubungi kula:

Aimee

Manajer sales

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Distrik Tianyuan, Kutha Zhuzhou.

Email:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

PRODUK RELATED

KIRIM KITA MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Tambah215, gedung 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

KIRIM KITA MAIL

HAK CIPTA :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy