Edemede

KPỌTỤRỤ ANYỊ

Ụlọ ọrụ na-ahụ maka ọrụ na-eme ihe na-eguzogide na-eguzogide heloy Sangey nozzles Tingsten Sanbide Nobide na - emepụta - 副本

Eobi:

Eobi:

Ụlọ ọrụ na-ahụ maka ọrụ na-eme ihe na-eguzogide na-eguzogide heloy Sangey nozzles Tingsten Sanbide Nobide na - emepụta - 副本

A na-eji carbide na-ciment nke eji eme ihe na ihe ciment carbide (superhard alloy). Carbide nozulu sitere na ịmịnye na-ekpo ọkụ na-ekpo ọkụ nke oghere na oghere. N'ihi ihe siri ike ya, njupụta dị ala na-eyi na-eyi na-eguzogide ya na-eguzogide ya na-agbasa na aja ọkụ, na-ejide na ngwaahịa ndị kachasị mma na ndị abrarive

.

1. 100% virgin raw materials.

2. Ụdị akara ule dị iche iche dị na ngwa ahịa.

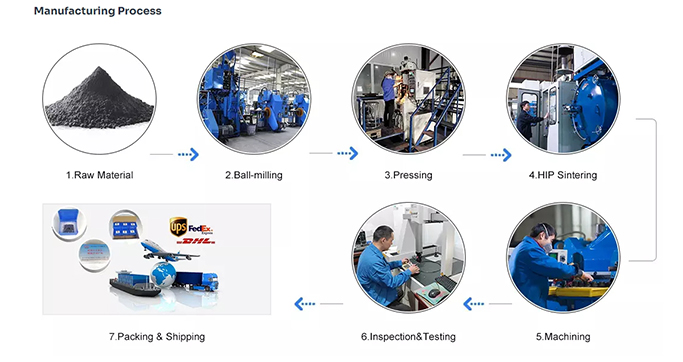

3. Anyị nwere akụrụngwa mmepụta dị elu na akụrụngwa iji hụ na ngwaahịa dị elu.

4

5

6. Teknụzụ dị elu, na-egweri.

Grade: YG6 / YG8 / YG6X / G10 / K10

Ọkọlọtọ akụkụ

| Mba. | OD (mm) | Id (mm) enwere ike idozi ya | Ogologo (mm) enwere ike idozi ya |

| 1 | 4 | 0.3-2 | 4.0-12 |

| 2 | 5 | 0.3-2 | 4.0-12 |

| 3 | 6 | 0.3-2 | 6.0-20 |

| 4 | 8 | 2.0-3.0 | 10-85 |

| 5 | 10 | 1.0-3.0 | 10-85 |

| 6 | 12 | 2.0-4.0 | 10-85 |

| 7 | 14 | 2.0-5.0 | 25-85 |

| 8 | 15 | 2.0-6.0 | 25-85 |

| 9 | 18 | 3.0-7.0 | 25-85 |

| 10 | 20 | 5.0-10.0 | 25-100 |

| 11 | 21 | 5.0-10.0 | 25-100 |

| 12 | 22 | 5.0-12.0 | 25-100 |

| 13 | 24 | 5.0-14.0 | 25-100 |

| 14 | 26 | 5.0-14.0 | 25-100 |

| 15 | 28 | 5.0-14.0 | 25-100 |

| 16 | 29 | 8.0-20.0 | 25-100 |

| 17 | 30 | 12-20.0 | 25-100 |

Kedu ihe kpatara k'ọpụ tungsten Carbide nozulu

Mgbe a na-apụghị izere ime ihe ike na usoro mgbasa ozi eji egbutu Abrasives (iko ígwè, mineral, mineral, carzzage nwere uru akụ na ụba na ndụ ogologo oge. N'oge ọdịnala, Tungsten Carbide bụ nhọrọ kacha mma maka ihe nke nozzles.

A na-eji ha na-eme ihe n'ọtụtụ ebe ọgwụgwọ, na-ese, eserese, elektrọniki, usoro kemịkal na ngwa ndị ọzọ dị ka waya na-eme ka ọ dị na ngalaba ndị ọzọ.

Ajụjụ:

Q1: Ị bụ Factory ma ọ bụ trading ụlọ ọrụ?

Anyị bụ Factory na 12 afọ nke mmepụta ahụmahụ.

Q2: Ebee ka ụlọ ọrụ gị dị?

Anyị nọ n'obodo Zhuzhou, mpaghara Hunan ebe isi tungsten carbide dị.

Q3: Ọnụ ahịa a na-asọmpi?

Anyị nwere Factory nke anyị. Ekele maka mmepụta na usoro nkesa siri ike, anyị na-ekwe nkwa ịnye ndị ahịa anyị ọnụahịa kachasị asọmpi.

Q4: Ngwaahịa ndị a hà dị oke mma?

Ee. A ga-anwale ngwaahịa niile tupu mmepụta nnukwu, na anyị ga-elele ihe anụ ahụ, ọdịdị na ndidi maka ijide n'aka na ngwaahịa ruru eru tupu mbupu.

Enwere onwe gị ịkpọtụrụ m:

Aimee

Onye njikwa ịre ahịa

Ụgwọ nke ụlọ ọrụ Zhuzhou Chuangde Cemented Carbide Co., Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Distrikti, City Zhuzhou .

Email:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

WhatsApp/wechat/Skype: 0086 13786352688

Ngwaahịa metụtara

Zipu ozi anyi

Ụgwọ nke ụlọ ọrụ Zhuzhou Chuangde Cemented Carbide Co., Ltd

Igbako215, ụlọ 1, Ogige Ọsụ Ụzọ Mba Nile, Taishan Road, Tianyuan District, Obodo Zhuzhou

Zipu ozi anyi

Nwegherinsinka :Ụgwọ nke ụlọ ọrụ Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy