Edemede

KPỌTỤRỤ ANYỊ

Ike na-eche ihu na-eche nche nke na-agba ọla kọpa na mmiri

Eobi:

Eobi:

Ike na-eche ihu na-eche nche nke na-agba ọla kọpa na mmiri

Tingsten Carvide Wod na-agbado ụgbọ mmiri na-eche ihu na-eche ihu / ịlinglụ na-eji agba ọla edo

A na-eme mkpanaka carbiding carbide na-eme site na ịgwakọta ciment ciment ciment ciment na ọla kọpa ka nkekọ site na ebe dị elu. Ọ bụ usoro a na-eme, ma a na-akpọkwa oke bekee "wolf ezé" n'ihi na -eme ka alloy ahụ dị n'elu mkpanaka. Ihe ndị ahụ na-eme ka a na-adọba ụgbọala na HC-Co ciment, na HRRA89.5-91; A na-ekewa nkekọ nke jikọtara ọnụ na alloy Alloy na Nickel nke sitere na Alloy; Ọ dị mma maka usoro ịgbado oxingụ oxingụ, na-acha ọkụ ọkụ nke ihe dị ka1000 ℃.

| Metric (MM) | Inch | |

| Nha nha | 1.6-3.2 | 1/16”-1/8” |

| 3.2-4.8 | 1/8”-3/16” | |

| 4.8-6.4 | 3/16”-1/4” | |

| 6.4-8.0 | 1/4”-5/16” | |

| 8.0-9.5 | 5/16”-3/8” | |

| Ụdị pụrụ iche na-atọgbọ cunssten carbide ndụmọdụ | ||

| Enwere ike ịhazi nha site na arịrịọ ndị ahịa. | ||

Ihe mmeputa nke Ọla kọpa ma ọ bụ nickel tungsten carbide rod ciment carbise na-agbaso mkpado

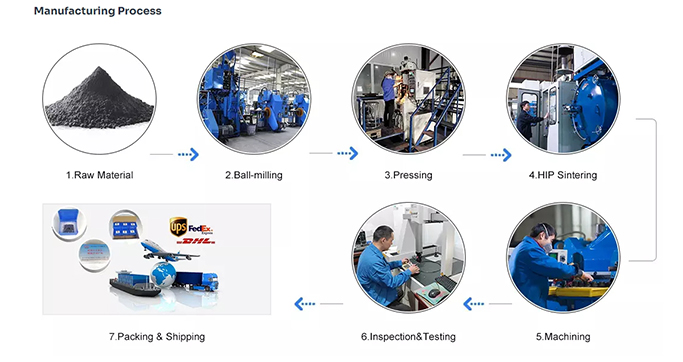

Oxygènettylene, usoro arụmọrụ dị ka ndị a:

(1) Ghichaa workpiece, mee ka ndị na-agba ọkụ na-agba ọkụ.

(2) Ọnọdụ dị larịị nke ịgbado ọkụ, ya mere nwere ike iji ngwa ndozi kwesịrị ekwesị maka njikwa nke sọks oyi akwa ọkpụrụkpụ, nnukwu mpempe dị.

(3) Site na nnọchi anya na-atọ ụtọ, ire ọkụ abụghị ịkpọtụrụ ihu, anya ruo 25 mm nwere amamihe.

(4) crafting softing na-agbado oyi akwa. Udiri aka ọla, nwere ike iji aka ekpe na mkpịsị aka Alloy Electrode na-ejikwa ya na ngwa ngwa.

(5) Mgbe ị na-enye ọrụ mgbakwunye, ebe enweghị ikuku, na-enweghị ike ịkpụ, enweghị ike ịkpụcha mkpuchi asestos.

(6) workiece With mgbe oyi na-ajụ oyi n'ime ụlọ okpomọkụ, ma ọ bụrụ na ọ dị mkpa, na-egwepịa elu ihu na udi.

(7) Mepee workpiece, wepu ihe mgbawa, slag, wdg.

Ngwa

A na-eji usoro carbiding carbiding sọọsọ na-ejikarị maka ihe na-acha uhie uhie ma ọ bụ igbutu

Petroleum, Nmapụta, minking, ihe eji eme ihe, ihe owuwu, ndị na-ese ihe, na-agbaze, na-acha uhie uhie, na-ata ata, na-eteta, wdg bets, wdg bets, wdg bets, wdg bets, wdg.

Mbukota

Kwụpụ 1, carbod carbide na-agwụ ike na mpempe akwụkwọ iji zere carbide eriri na-agwụ ike iji gbajie

Kwụpụ 2, tinye carbide eri na-agwụ ike n'ime obere igbe obere katọn

Nzọụkwụ 3, tinye igbe n'ime katọn na-apụta ma jupụta katọn na-acha uhie uhie

Kwụpụ 4, kechie katọn na teepu ngwugwu

Kwụpụ 5, ị nwere ike ịhọrọ ụzọ nnyefe ọ bụla dịka DHL, TNT, UPS ECT.

Ajụjụ:

Q1: Ị bụ Factory ma ọ bụ trading ụlọ ọrụ?

Anyị bụ Factory na 12 afọ nke mmepụta ahụmahụ.

Q2: Ebee ka ụlọ ọrụ gị dị?

Anyị nọ n'obodo Zhuzhou, mpaghara Hunan ebe isi tungsten carbide dị.

Q3: Ọnụ ahịa a na-asọmpi?

Anyị nwere Factory nke anyị. Ekele maka mmepụta na usoro nkesa siri ike, anyị na-ekwe nkwa ịnye ndị ahịa anyị ọnụahịa kachasị asọmpi.

Q4: Ngwaahịa ndị a hà dị oke mma?

Ee. A ga-anwale ngwaahịa niile tupu mmepụta nnukwu, na anyị ga-elele ihe anụ ahụ, ọdịdị na ndidi maka ijide n'aka na ngwaahịa ruru eru tupu mbupu.

Enwere onwe gị ịkpọtụrụ m:

Aimee

Onye njikwa ịre ahịa

Ụgwọ nke ụlọ ọrụ Zhuzhou Chuangde Cemented Carbide Co., Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Distrikti, City Zhuzhou .

Email:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

WhatsApp/wechat/Skype: 0086 13786352688

Ngwaahịa metụtara

Zipu ozi anyi

Ụgwọ nke ụlọ ọrụ Zhuzhou Chuangde Cemented Carbide Co., Ltd

Igbako215, ụlọ 1, Ogige Ọsụ Ụzọ Mba Nile, Taishan Road, Tianyuan District, Obodo Zhuzhou

Zipu ozi anyi

Nwegherinsinka :Ụgwọ nke ụlọ ọrụ Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy