KATEGORI

KONTAKTE NOU

China Tungsten Carbide Studs Manufacture and Factory

Imèl:

Imèl:

China Tungsten Carbide Studs Manufacture and Factory

Factory supply YG11 YG20 Tungsten Carbide Stud For HPGR Cemented Carbide Segments

Description

Grade: YG11C, YG13C, YG15, YG20

Advatages: high wear resistance and high compressive strength,high work efficiency

Service life: 8000-10000 hrs for iron ore crushing and over 25000hrs for cement crushing

we have professional engineers to make the drawing per customer’s requirement:

with product size, we can provide drawing.

with sample delivered to us, we can provide drawing.

with picture of product, we can provide drawing.

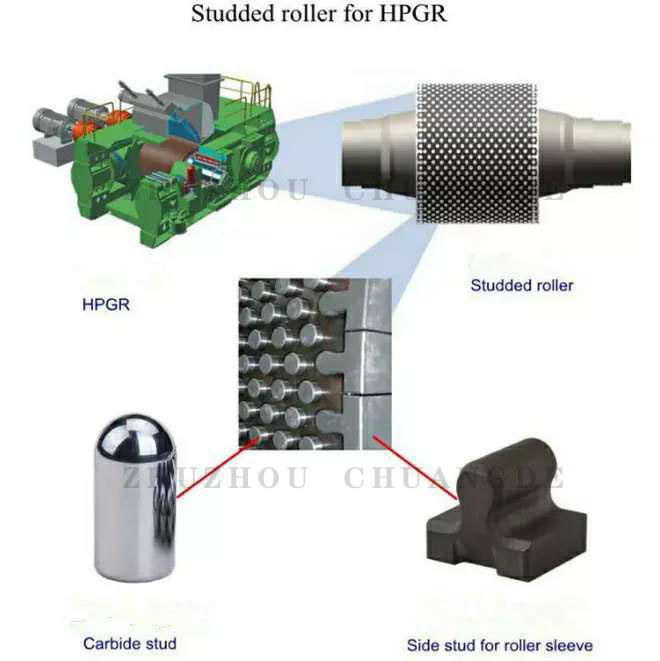

Application of Cemented Carbide stud for HPGR grind ore and cement

High Pressure Grinding Roller is an energy-efficient crushing equipment of new technologies, widely used in grinding cement clinker,limestone,bauxite,iron ore..The High Pressure Grinding Roller as crushing equipment., the roller sleeve of the HPGR is the core and small component on the key equipments such as cement, mine, thermoelectricity and coal chemical. Its performance directly determines the output efficiency of the production line. High performance of carbide stud extends the life of High Pressure Grinding Roller. Zhuzhou Chuangde provide quality carbide studs with good wear resistance and high compressive strength, can satisfy the requirements of different conditions.

Our Advantages:

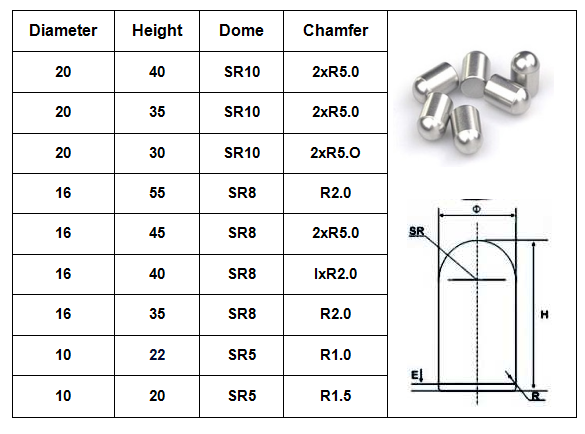

1.Hemispherical top, protect the studs from being destroyed by stress concentration.

2.Round edges, protect the stubs being damaged during production, transportation, installment and using.

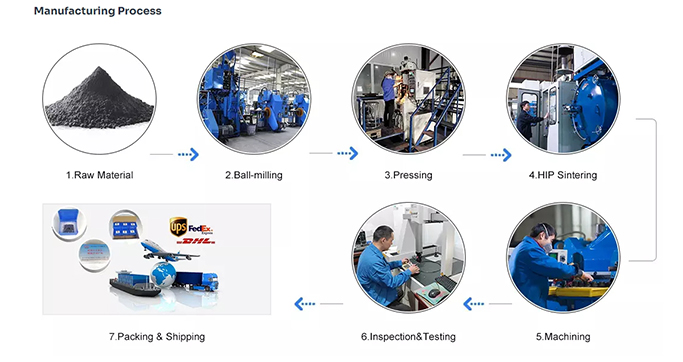

3.HIP sintering ensure good compactness and high toughness for the products.

4.Special technology to eliminate the surface stress after surface grinding, and increase the surface hardness at the same time.

5.Grease used on surface of the products to avoid oxidization.

Grades below are exclusive grades we developed for rolling machine. Good wear resistance and high strength are suitable for metal smashing with high working efficiency. Lifetime of carbide stud is over 8000-10000 hrs iron ore and 25000hrs for cement.

| Grade | Hardness(HRA) | Bending Strengh (≥N/mm²) | Density | Coercivity(Ka/m) | Cobalt | Carbon |

| YG15C | 85-86.5 | 2500 | 13.9-14.1 | 4.5-6.5 | 14.7-15.3 | 4.9-5.5 |

| YG20 | 86-87.5 | 2450 | 13.4-13.6 | 8.0-11.0 | 19.7-20.3 | 4.5-4.8 |

| YG15 | 87-88.5 | 2800 | 13.95-14.15 | 7.0-10.0 | 14.1-14.8 | 4.95-5.6 |

| CD650 | 87.8-90 | 2950 | 13.95-14.15 | 8.0-10.5 | 14.5-14.9 | |

| CD20 | 85.8-87.3 | 2600 | 13.89-14.2 | 5.8-8.0 | 14.8-15.2 |

All the products must be inspected strictly with the ultrasonic and only those haven't any harm such as pore can be shipped out. High density, high wear & impact resistance, which lead them a long lifetime.

For the crushing of High pressure grinding roller, iron ore, cement crushing

Product description: Tungsten carbide stud pins are mainly used for the High pressure grinding roller HPGR as the core compoment, which proivde high wear resistance and high compressive strength for the roller.

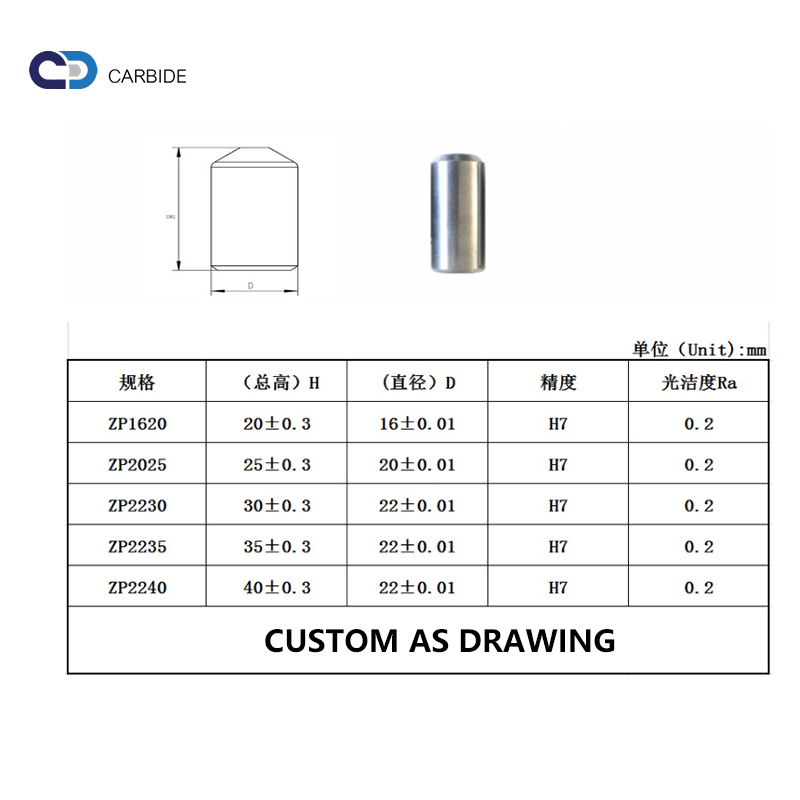

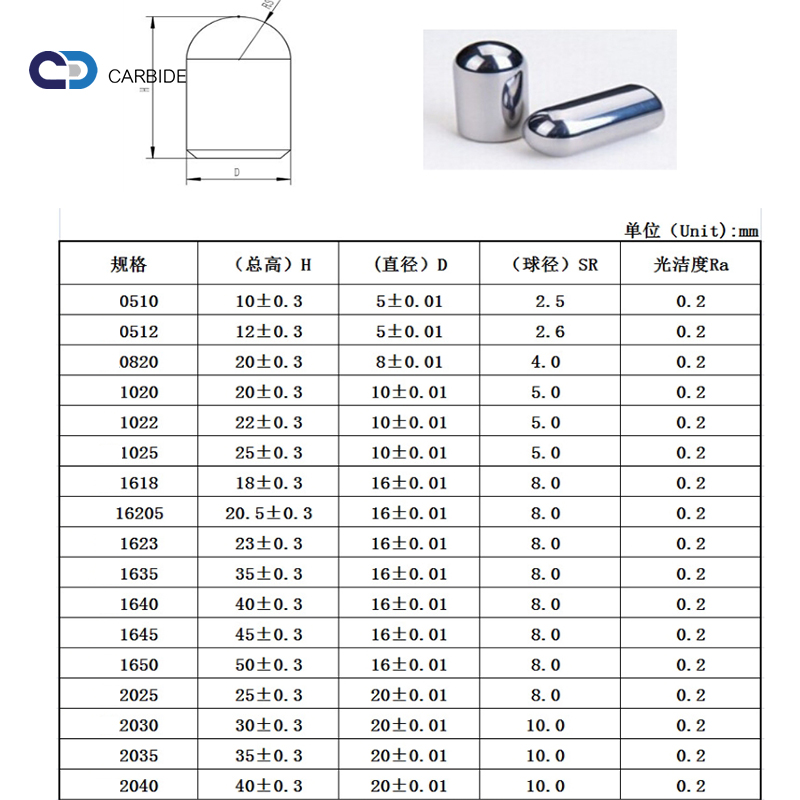

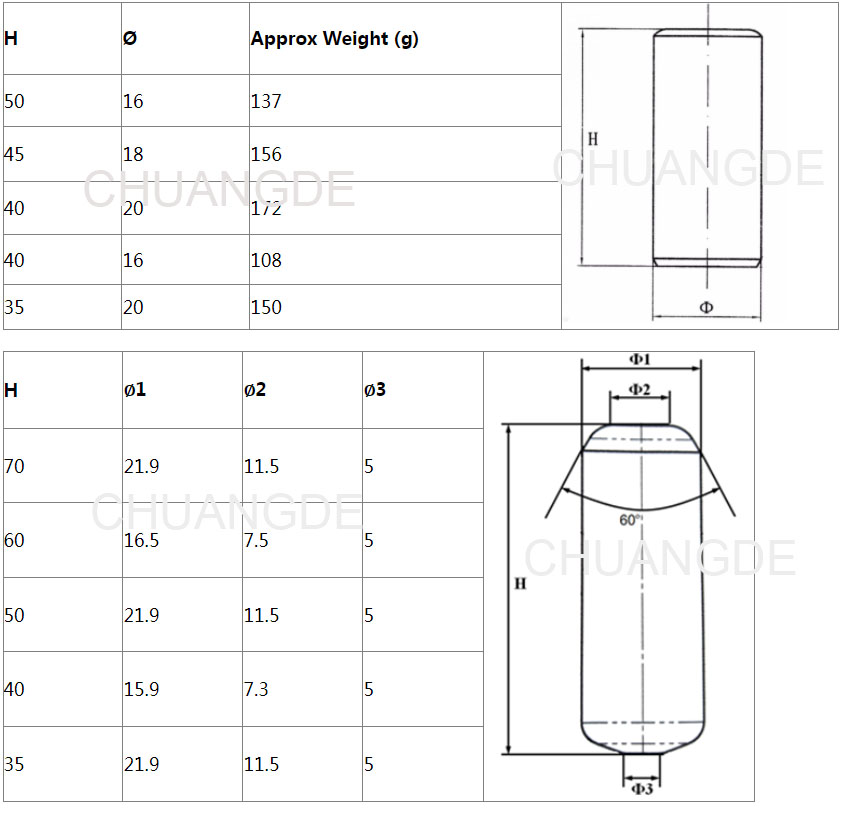

Dimensions

FAQ:

Q1: Èske ou faktori oswa konpayi komès?

Nou se faktori ak 12 ane eksperyans nan pwodiksyon.

Q2: Ki kote faktori ou ye?

Nou sitiye nan vil Zhuzhou, pwovens Hunan kote se baz carbure tengstèn.

Q3: Èske pri a konpetitif?

Nou gen faktori pwòp nou yo. Mèsi a sistèm pwodiksyon ak distribisyon fò, nou pwomèt yo ofri kliyan nou yo pri ki pi konpetitif.

Q4: Èske pwodwi yo wo kalite?

Wi. Tout pwodwi yo pral teste anvan pwodiksyon esansyèl, epi nou pral tcheke pwopriyete fizik, fòm ak tolerans pou asire pwodwi ki kalifye anvan anbake.

Ou lib pou kontakte m:

Aimee

Manadjè lavant

Zhuzhou Chuangde Cemented Carbide Co Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Distri Tianyuan, Zhuzhou City.

Imèl:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

whatspp/wechat/Skype: 0086 13786352688

PWODWI ki gen rapò

VOYE MAY NOU

Zhuzhou Chuangde simante Carbide co, Ltd

Ajoute215, bilding 1, Entènasyonal Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

VOYE MAY NOU

DWA DWA :Zhuzhou Chuangde simante Carbide co, Ltd

Sitemap

XML

Privacy policy