CATEGORIES

Tiv tauj peb

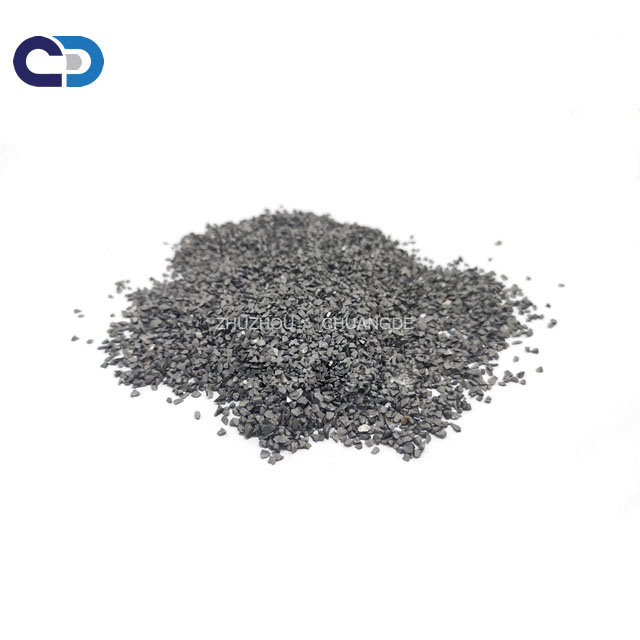

Manufacturer Hard facing bar Tungsten Carbide Grit tungsten carbide composite welding rod

Email:

Email:

Manufacturer Hard facing bar Tungsten Carbide Grit tungsten carbide composite welding rod

Manufacturer Hard facing bar Tungsten Carbide Grit tungsten carbide composite welding rod

Tungsten carbide copper Brazing Rod YD-5 it is made of by sintering tungsten carbide scrap and elastic matrix alloy,Outer layer of the special flux and coloring is marking scrap grade,the composition of sintering tungsten carbide scrap is mainly CO and WC,The hardness is HRA 89~91,tire body matal is Ni and copper alloy,strength can up to 690MPa, hardness HB≥160.

| Grade | Chemical Composition(Wt%) | |||

| Ni+Cu+Zn+Sn | Cu+Zn+Sn | WC | Co | |

| Cu-30 | -- | 30±2 | 63-65 | 5.2-6.0 |

| Cu-40 | -- | 40±2 | 53-56 | 4.6-4.8 |

| Cu-45 | -- | 45±2 | 48-52 | 4.2-4.5 |

| Cu-50 | -- | 50±2 | 44-48 | 3.8-4.2 |

| Ni-Cu-30 | 30±2 | -- | 63-65 | 5.2-6.0 |

| Ni-Cu-40 | 40±2 | -- | 53-56 | 4.6-4.8 |

| Ni-Cu-45 | 45±2 | -- | 48-52 | 4.2-4.5 |

| Ni-Cu-50 | 50±2 | -- | 44-48 | 3.8-4.2 |

| Metric (mm) | Inch | |

| Grain Size | 1.6-3.2 | 1/16”-1/8” |

| 3.2-4.8 | 1/8”-3/16” | |

| 4.8-6.4 | 3/16”-1/4” | |

| 6.4-8.0 | 1/4”-5/16” | |

| 8.0-9.5 | 5/16”-3/8” | |

| Special Shape Sintered Tungsten Carbide Tips | ||

| Size can be customed by customer's request. | ||

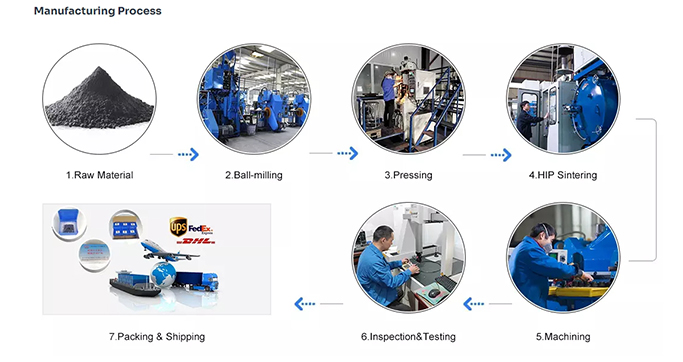

Production of Manufacturer Hard facing bar Tungsten Carbide Grit tungsten carbide composite welding rod

The oxyacetylene butt, the operating process is as follows:

(1) clean up the workpiece, make the welding workpieces surface with metallic luster.

(2) the flat position of welding, therefore can use the appropriate clamping fixture for control of surfacing layer thickness, thick piece of available.

(3) with a neutral flame preheating, flame core not contact surface, the distance to 25 mm is advisable.

(4) carbide surfacing welding layer.With YD type electrode surfacing, the use of neutral flame (can be slightly carbonizing flame) tip is steady on the workpiece surface movement, the flame of the alloy electrode heating (be careful not to make flame cone tip contact alloy particles), tire body in the electrode alloy melt, carbide particles are also falling.Before the tire body of molten metal solidification, the particles arrange, can use left hand of the alloy electrode fingers, or another person holding a base electrode or pull rod on graphite rod in a quick stir particles, making them evenly aligned neatly.Surfacing layer thickness control according to the requirements of design.

(5) after the workpiece welding, where no ventilation, slow cooling, cannot quench, conditional usable asbestos blanket cover.

(6) the workpiece after cooling to room temperature, if necessary, grinding surface surfacing to required size and shape.

(7) clean up the workpiece, remove all splash, slag, etc.

Application of Manufacturer Hard facing bar Tungsten Carbide Grit tungsten carbide composite welding rod

YG Series Cemented Carbide Surfacing Rod is mainly used for surfacing the severely worn or cut workpieces in

petroleum, mining, coal mining, geology, construction and other industries, such as milling shoes, grinding shoes, centralizers, reamers, drill pipe joints, hydraulic cutters, scraper blades, coal plough bits, coring bits, piling bits, auger bits, etc.

FAQ:

Q1: Koj puas yog Hoobkas lossis tuam txhab lag luam?

Peb yog Hoobkas nrog 12 xyoo kev tsim khoom.

Q2: Koj lub Hoobkas nyob qhov twg?

Peb nyob hauv Zhuzhou nroog, Hunan xeev uas yog lub hauv paus ntawm tungsten carbide .

Q3: Puas yog tus nqi sib tw?

Peb muaj peb lub Hoobkas. Ua tsaug rau kev tsim khoom muaj zog thiab kev faib tawm, peb cog lus tias yuav muab peb cov neeg siv khoom sib tw tshaj plaws.

Q4: Cov khoom puas zoo?

Yog lawm. Tag nrho cov khoom yuav raug kuaj ua ntej ntau lawm, thiab peb yuav xyuas cov khoom ntawm lub cev, cov duab thiab kev ua siab ntev kom ntseeg tau cov khoom tsim nyog ua ntej xa khoom.

Xav tias dawb hu rau kuv:

Aimee

Tus neeg muag khoom

Zhuzhou Chuangde Cemented Carbide Co., Ltd

215, building 1, International Students Pioneer Park,

Taishan Road, Tianyuan District, Zhuzhou City.

Email:yog info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

whatspp/wechat/Skype: 0086 13786352688

QHOV CHAW UA HAUJ LWM

Xa ntawv rau peb

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Ntxiv215, lub tsev 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

Xa ntawv rau peb

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy