NA WAIWAI

KĀHEA IĀ MĀ˚OU

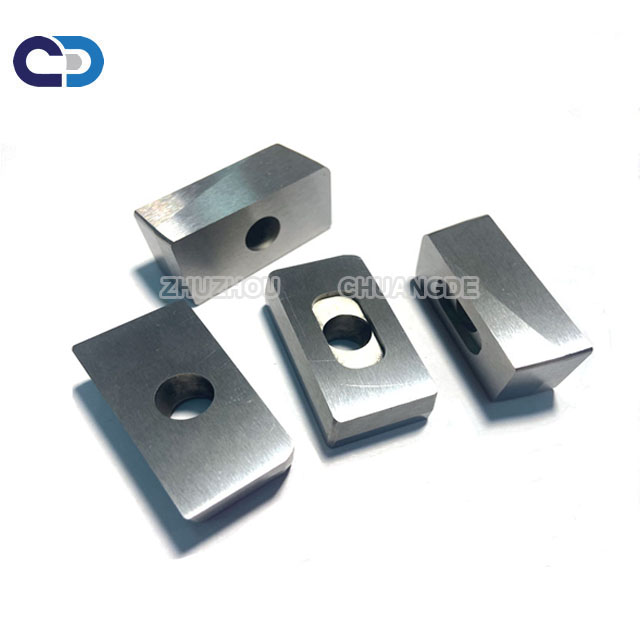

Tungsten carbide cold heading die for punching screw nut

leka uila:

leka uila:

Tungsten carbide cold heading die for punching screw nut

Description of product of Tungsten carbide cold heading die for punching screw nut

1.Corrosion cemented carbide: cemented carbide electric corrosion layer is thinner, the micro defect of machined surface is reduced, and the surface quality of cemented carbide is improved.

2. Grain structure: tungsten carbide is more uniform, more rounded corners, more uniform stress distribution, improve cemented carbide

Features of tungsten carbide Tungsten carbide cold heading die for punching screw nut

1) Extension of die life and stability of life

By controlling the particle size distribution of WC, can make the plastic deformation and reduce the load of thecemented carbide to improve the compressive strength and fracture toughness, delaying the occurrence and propagation of cracks of the mould process, long service life, and has a very high consistency .

2) Bite and adhesion decreased considerably

High temperature single crystal WC was used to strengthen the binding of crystalline structure and effectively strengthen the cobalt phase, thus effectively inhibiting the cracking of the material .

3) The corrosion resistance and electrical resistance of the cemented carbide are improved

Because of the strengthening of the cobalt phase, the corrosion resistance of the cemented carbide is greatly improved, so that the cemented carbide is suitable for discharge machining.

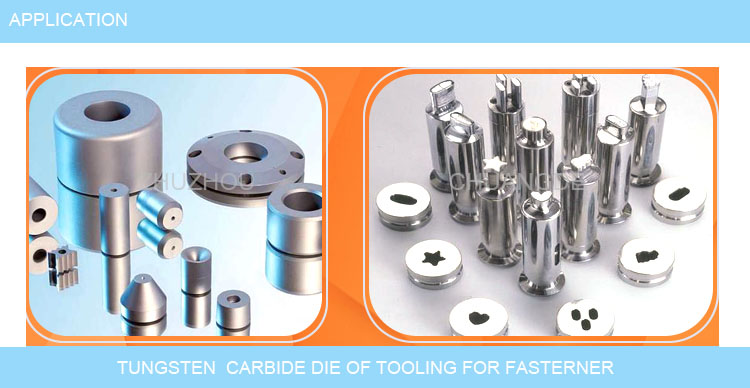

Applications :

Tungsten carbide pellets dies are widely used in cold heading,forging,stamping and punching dies for maufacturing round nuts, screw caps, bolts, cans and many other products.

| Grade | Density g/cm3 | Hardness HRA | T.R.S Mpa | Performance&application recommended |

| YG20 | 13.5 | 85.5 | 2800 | It is suitable for manufacturing punching dies for watch parts,leaf spring of musical instrument,battery jars,small sized steel balls,screws,screw caps,etc |

| YG16C | 13.9 | 85 | 2750 | It is suitable for impact-resistant forging dies |

| YG18C | 13.7 | 84 | 2800 | It is suitable for impact-resistant forging dies,hot-forging dies and finishing rollers |

| YG20C | 13.5 | 83 | 2850 | It is suitable for wear resistant or impact resistant dies |

| YG22C | 13.3 | 82 | 2900 | It is suitable for nut forming dies and high impact-resistant dies |

| YG25C | 13.1 | 81.5 | 3000 | It is suitable for stainless screw dies and semifinishing rollers |

| Other grades and sizes can be offered as per customers' requirement | ||||

Our Advantages :

1.Strong Mould R&D team. We support product customization as per specific requirements, ensure high working efficiency with good product quality .

2.Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

3.Strong R&D team. Professional engineers serve for clients, recommend products and grades as per your applications. We also offer after-sale service .

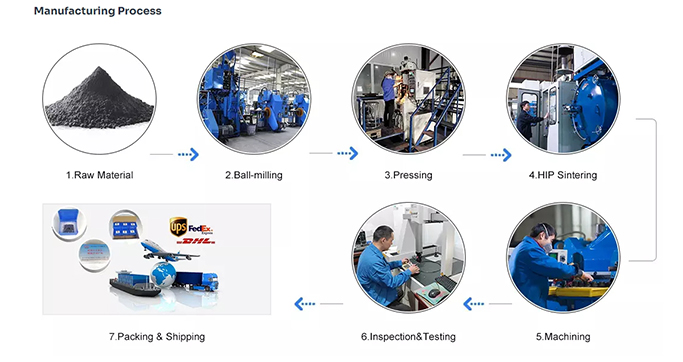

4.100% raw material for production.6. Hip sintered, reliable hardness, durable wear resistance

5. Various sizes, carbide grade and full types available

6. Competitive price with on-time delivery

7. Customized product as per drawing and small order accepted,professional and in-time technical support .

FAQ:

Q1: ʻO ʻoe ʻo Factory a i ʻole ʻoihana kālepa?

ʻO mākou ʻo Factory me 12 mau makahiki o ka ʻike hana.

Q2: Aia i hea kāu hale hana?

Aia mākou ma ke kūlanakauhale ʻo Zhuzhou, ka ʻāina ʻo Hunan kahi kumu o ka tungsten carbide.

Q3: He mea hoʻokūkū ke kumukūʻai?

Loaʻa iā mākou kā mākou Factory pono'ī. Mahalo i ka hana ikaika a me ka ʻōnaehana hoʻolaha, hoʻohiki mākou e hāʻawi i kā mākou mea kūʻai aku i ke kumukūʻai hoʻokūkū.

Q4: ʻO nā huahana High Quality?

ʻAe. E hoʻāʻo ʻia nā huahana āpau ma mua o ka hana nui, a e nānā mākou i nā waiwai kino, ke ʻano a me ka hoʻomanawanui no ka hōʻoia ʻana i nā huahana kūpono ma mua o ka hoʻouna ʻana.

E ʻoluʻolu e kelepona mai iaʻu:

Aimee

Luna kuai

ʻO Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

Alanui Taishan, Apana Tianyuan, Kulanakauhale o Zhuzhou.

leka uila:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

NA HUAKAI PILI

E HOEA MAI I KA LEKA

ʻO Zhuzhou Chuangde Cemented Carbide Co., Ltd

Hoʻohui215, hale 1, International Student Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

E HOEA MAI I KA LEKA

KUMU KOPE :ʻO Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy