17

2024

-

07

Industrial Teeth - Carbide Button

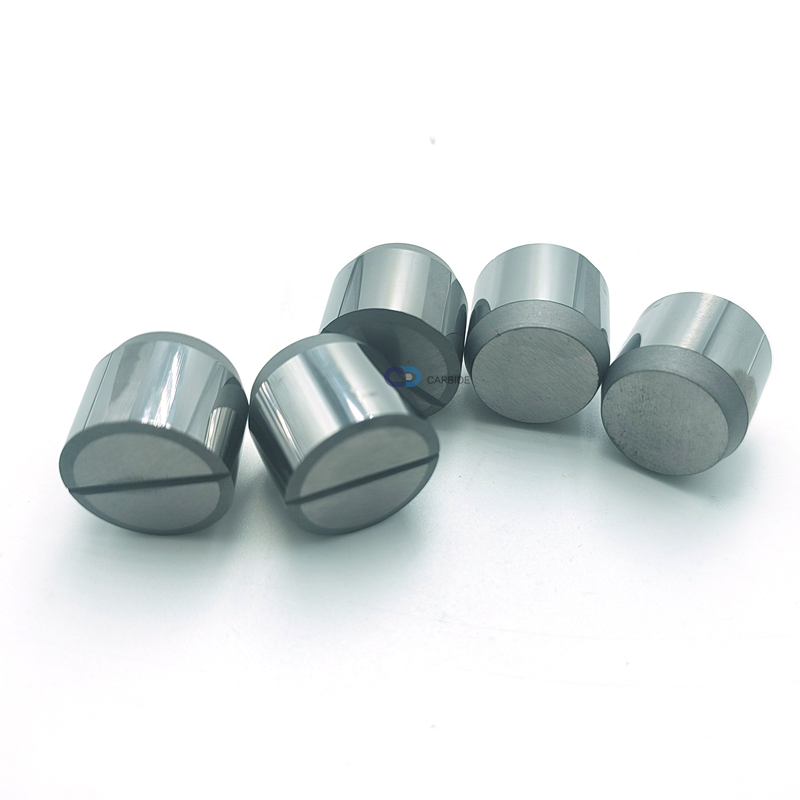

"Industrial Teeth - Carbide Buttons"

Carbide button teeth have the characteristics of high hardness, strong wear resistance, and high compressive strength. They are widely used in industrial fields such as mining, geological exploration, tunneling, and engineering construction. Just like teeth play an important role in chewing and crushing food, carbide button teeth undertake key tasks such as crushing, cutting, and excavation in industrial operations.

Application

1.Mining: drill bits and drilling tools used in drilling, rock drilling, blasting and other operations, such as mining coal mines, metal mines, etc.

2.Geological exploration: crushing rocks in geological drilling to obtain underground geological samples.

3.Oil and gas mining: drill bit components in drilling operations to improve drilling efficiency.

4.Tunneling: tools used for tunneling equipment to crush rocks and soil.

5.Road construction: used to crush road surfaces and rocks during road construction and maintenance.

6.Building demolition: crushing concrete and masonry structures when demolishing buildings.

7.Foundation engineering: drilling tools in pile foundation construction.

8.Stone mining: used to mine marble, granite and other stones.

In short, carbide ball teeth may be used in all operations involving crushing, drilling and excavation of hard materials such as rocks, ores, concrete, etc.

How to choose the right carbide ball teeth?

Application scenarios and working conditions

Balance of hardness and toughness

Size and shape

Material and composition

Selection of carbide ball teeth

1. Working conditions with high hardness and wear resistance requirements, such as highly abrasive rock mining:YG8 and YG10, which contain a higher proportion of tungsten carbide and have excellent wear resistance.

2. Operations with large impact loads, such as impact drilling:YG13C and YG15 may be more suitable because they have good toughness and impact resistance while maintaining a certain hardness.

3. Working in high temperature environments: YG6X.

4. General mining and engineering construction: YG6, YG11, etc. are more commonly used grades that can achieve a good balance between hardness, toughness and cost.

Our Product Show

Kudin hannun jari Zhuzhou Chuangde Cemented Carbide Co., Ltd

Ƙara215, gini 1, Filin Majagaba na Ƙasashen Duniya, Titin Taishan, gundumar Tianyuan, birnin Zhuzhou

Aiko da wasiku

HAKKIN KYAUTA :Kudin hannun jari Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy