05

2024

-

12

Chunnaic tgsgsten blade fiaclan lann: roghainn fìor mhath ann an gearradh stàilinn

Chunnaic tgsgsten blade fiaclan lann: roghainn fìor mhath ann an gearradh stàilinn

Ro-shealladh toraidh

Moladh agus feartan: Chunnaic na prìomh phàirtean de bhàillte pùdar lann agus pùdar agus pùdar agus pùdar agus pùdar niclt. Tha feartan neo-eisimeileach tgsgsten carbide a 'cur an aghaidh an aghaidh agus an aghaidh creimneach, a bheir comas do fhiaclan lann a-steach gus deagh choileanadh a chumail suas ann an diofar àrainneachdan gearradh cruaidh, mar sin a' leudachadh beatha na seirbheis. Tha e air a chleachdadh gu farsaing ann an innealan gearradh, molltairean, petroleum agus gnìomhachasan càrail.

Buannachdan:

Stuthan amh-inbhe àrd-inbhe: 100% Stuthan amh fìor-ghlan Dèan cinnteach gu bheil càileachd bunaiteach an toraidh agus na bunait airson a choileanadh àrd.

Cuir strì air sàr-mhath: Rè a 'phròiseas gearradh, faodaidh e an aghaidh caitheamh stàilinn air fiaclan bhon lagh, agus èifeachdas obrach a bhith a' leasachadh èifeachdas obrach.

A 'toirt aghaidh a' bhuaidh làidir: A 'coimhead buaidh crathaidh agus cleasan eile ann an gearradh, chan eil duilgheadasan ann a bhith a' tuiteam, a 'dèanamh dèanamh cinnteach gu bheil adhartas fialinn a' lughdachadh obair gearraidh.

Togalaichean ceimigeach seasmhach: Ann an diofar àrainneachdan obrach, chan eil e furasta dèiligeadh gu ceimigeil ri stuthan eile agus a 'dèanamh cinnteach gum bi fiaclan blade a' faicinn.

Làimhseachadh uachdar math: Às deidh làimhseachadh uachdar faiceallach, tha an coltas foirfe, agus tha e cuideachd a 'cuideachadh toirt air falbh chip agus a' lughdachadh strì aig a 'ghearradh.

Easy a 'brathadh: furasta a dhèanamh airson a bhith a' dèanamh agus a chàradh, a 'lughdachadh duilgheadasan tomhais-pàighidh agus duilgheadasan cumail suas.

Faodar Madhalan àrd toinnte: air a dhèanamh de mhollaidhean mionaideach, faodar an dearbhadh taobh a-muigh na h-àrd agus èideadh, agus faodar gearradh nas ceart a choileanadh.

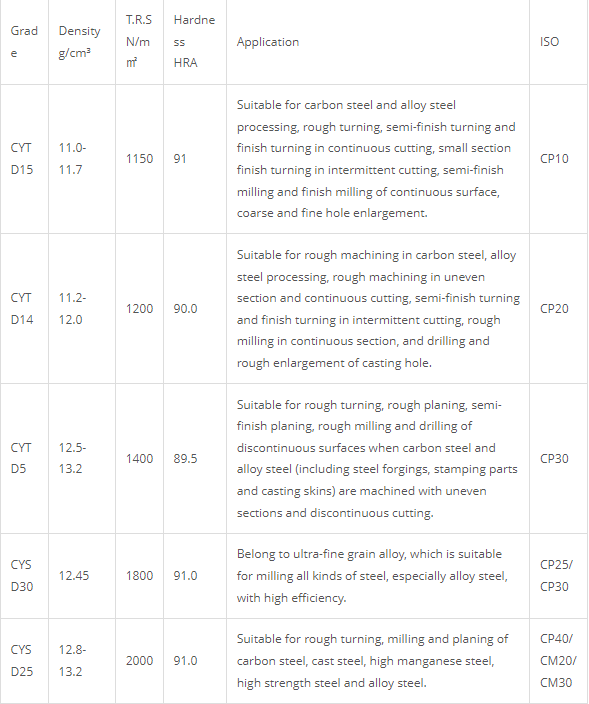

Diofar sheòrsan is ìrean: Thoir seachad grunn sheòrsaichean agus ìrean, agus tagh fiaclan lann freagarrach a rèir diofar stuthan stàilinn, msaa gus coinneachadh ri feumalachdan eadar-mheasgte.

Sgìrean tagraidh

Gnìomhachas giullachd meatailt: Ann an stuthan saothrachaidh Faodar fiaclan lann a ghearradh, leithid fìor stàilinn àrd, stàilinn gualain, msaa, pàirtean meacanaigeach. Mar eisimpleir, ann an saothrachadh einnsean automobile, feumar diofar sheòrsaichean stàilinn a ghearradh gu ceart. Rug TUNGSTED PADESED FÀILT Faodaidh fiaclan lann coinneachadh ri riatanasan cruinneachaidh agus gearradh àrd-eòlas, dèanamh cinnteach à càileachd agus coileanadh pàirtean einnsean.

Giullachd stàilinn togail:

Airson an ìre mhòr de ghearradh pròifil stàilinn gualain a tha riatanach gnìomhachas togail, chunnaic Tungten Carbide a 'coileanadh gu math. Mar eisimpleir, ann an togail frèamaichean togail, feumar pròifilean stàilinn gualain a ghearradh ann an diofar fhaid agus chumaidhean. Faodaidh fiaclan lann sàbhaidh an obair gearradh a lìonadh gu sgiobalta agus gu ceart, a 'leasachadh èifeachdas togail.

Raointean eile:

A bharrachd air na prìomh raointean tagraidh gu h-àrd, chunnaic fiaclan soilleir a 'faicinn fiaclan lann gu h-àrd anns a bheil fiaclan lann gu h-àrd, tha tagraidhean agus raointean rèile agus raointean eile a dh' fheumas dearbhadh agus càileachd gearradh stàilinn glè àrd àrd àrd. Anns an raon Aerospace, thathas ga chleachdadh gus cuid de na stàlaichean àrda àrd-ìre agus àrd-inbhe a ghearradh gus pàirtean einnsean itealain itealain a ghearradh, àrdaich pàirtean structarail, msaa.

Roinn toraidh

Le seòrsachadh stuthan: faodar a roinn ann an sàsachadh fìor-ghlan a 'bhlad a-mach agus a' t-thungten ungy Alloy fiaclan lann. Sawssten tangssed past a 'faicinn fiaclan lann, ach droch bhualadh; TUNGSSTETES BOSEY SHLAY SHLAY FIOSRACHADH LODE A DHÈANAMH A DHÈANAMH A DHÈANAMH A DHÈANAMH A DHÈANAMH A 'GABHAIL A' GABHAIL A 'GABHAIL A' GABHAIL A 'GABHAIL A' GABHAIL A 'GABHAIL A' cur eileamaidean eadar-dhealaichte eile ris, agus bidh coileanadh coileanta nas fheàrr a chur orra.

Seòrsachadh a rèir cleachdadh: Tha fiaclan lann is farsaingeachd coitcheann ann agus a chunnaic fiaclan lann sònraichte. An seòrsa coitcheann freagarrach airson a bhith a 'gearradh stuthan meatailt coitcheann; Tha Seòrsa sònraichte air a dhealbhadh airson stuthan sònraichte no feumalachdan giollachd sònraichte, leithid stàilinn cainty agus stuthan duilich agus duilich, le biontan làidir agus proifeiseantachd.

Gluasadan margaidh agus leasachadh margaidh

Fàs meud margaidh: Anns na bliadhnachan mu dheireadh, le leasachadh leantainneach air gnìomhachas saothrachaidh, tha an t-iarrtas airson innealan gearraidh àrd-thoileach a 'sìor fhàs a' leantainn air fiaclan fàis a nochdadh. A rèir aithisgean buntainneach, seallaidh Còmhlan Sìneach Planden Bloddstes a 'leudachadh bho 2024 gu 2030, agus tha na cothroman àrd-ghnìomhach farsaing.

Dreuchd ùr-ghnàthach Teicneòlas: Tha iomairtean a 'leantainn air adhart a' meudachadh tasgadh R & D gus ùr-ghnàthachadh teicneòlais de bhàillidh a bhrosnachadh fiaclan lann. Mar eisimpleir, rannsachadh agus leasachadh teicneòlas ullachaidh pùdar mòr-choileanadh àrd-bhuidseach agus pròiseasan saothrachaidh nas adhartaiche gus cruadhachd a leasachadh fiaclan bho mhargaidh airson innealan gearradh àrd-inbhe.

Leudachadh làraich tagraidh: Leis gu leantainneach de stuthan ùra agus pròiseasan ùra, chunnaic an raon tagraidh de fhiaclan lann a-steach. A bharrachd air an raon giullachd meatailt traidiseanta, bidh e cuideachd air a chleachdadh nas fharsainge ann an raointean a tha a 'tighinn am bàrr leithid lùth ùra agus fiosrachadh dealanach, a' toirt puingean fàis ùra airson leasachadh a 'ghnìomhachais.

Tha farpais a 'mhargaidh ag òrdachadh: Tha fàs iarrtas a' mhargaidh air mòran chompanaidhean a tharraing a-steach don ghnìomhachas fialaidh Sungsten Carbide, agus tha farpais a 'mhargaidh a' sìor fhàs fiadhaich. Feumaidh iomairtean gus càileachd toraidh a leasachadh, lughdaich cosgaisean, a 'neartachadh togail togail agus adhartachadh margaidh gus am margaidh aca a neartachadh.

Duilgheadasan teignigeach agus fuasglaidhean a dh 'fhaodadh a bhith air tachairt rè cleachdaidh

A 'gearradh dearbhaidhean dearbhaidhean dearbhaidh: rè cleachdadh, is dòcha nach bi cruinneas gearradh gu leòr ann, a dh' fhaodadh a bhith air adhbhrachadh le mionaideachd stàlaidh gu leòr de fhiaclan lann agus cus teasairginn. Am measg nam fuasglaidhean: A 'dèanamh cinnteach gu bheil cruinneas stàlaidh a' faicinn fiaclan lann, a 'cleachdadh innealan agus modhan stàlaidh proifeasanta; gu cunbhalach a 'sgrùdadh ruitheamaid a tha a' ruith a 'chrann a bha a' ruith a-mach, agus a 'atharrachadh no a' dol an àite lannan fhaicinn ann an àm.

Tha caitheamh fiacail de lannan sàbhaidh ro luath: Ged Tha lannan tiugh a 'faicinn lannan fèithe math air lannan, is dòcha gu bheil iad fhathast ro luath fo chuid de shuidheachadh gearraidh sònraichte, leithid gearradh stàilinn àrd agus gearradh leantainneach fad-ùine. Am measg nam fuasglaidhean tha: a 'taghadh ìre fiacail lann agus modail iomchaidh a rèir an stuth gearraidh agus suidheachadh obrach; a 'cur an aghaidh paramadairean gòrach, leithid gearradh astar is biadhaidh, gus caitheamh caitheamh fiaclan a lughdachadh; gu cunbhalach a 'bleith fiaclan lann gus an coileanadh gearraidh aca a thoirt air ais.

Iongantas briseadh fhiacail: Nuair a choinnicheas e ri luchd mòr buaidh aig a 'phròiseas gearraidh, dh' fhaodadh e fiaclan lann sàbhaidh a bhriseadh. Am measg nam fuasglaidhean tha: A 'taghadh ìre fiacail lann is fiacail lann le buaidh a' bhuaidh nas làidire; A 'sgrùdadh seasmhachd an uidheamachd gearraidh gus dèanamh cinnteach nach eil cus crith tron phròiseas gearraidh; a 'dèiligeadh ris a' stàilinn mus gearradh thu, leithid a bhith a 'toirt air falbh craiceann cruaidh agus neo-chunbhalach air an uachdar, gus an luchd a' bhuaidh a th 'ann aig a ghearradh.

Thoir air falbh chip bochd: Ma tha toirt air falbh Chip rèidh, bheir e an teòthachd san àite gèilleadh ri àrdachadh, agus eadhon buaidh a thoirt air càileachd gearradh. Tha na fuasglaidhean a 'toirt a-steach: a' cumail sùil air làimhseachadh uachdar an fhiaclan lann sàbhaidh gus dèanamh cinnteach à coileanadh mu thoirt air falbh chip gip; a 'dèanamh an fheum as fheàrr air a' phròiseas gearraidh, leithid cleachdadh nan co-fhulanta, ag atharrachadh an ceàrn gearraidh, msaa., gus suidheachaidhean toraidh chip a leasachadh.

Naidheachdan co-cheangailte

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Cuir ris215, togalach 1, Pàirc Pioneer Oileanaich Eadar-nàiseanta, Rathad Taishan, Sgìre Tianyuan, Cathair Zhuzhou

Cuir post thugainn

Dlighe-sgrìobhaidh :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy