KATEGOORIAD

VÕTA MEIEGA ÜHENDUST

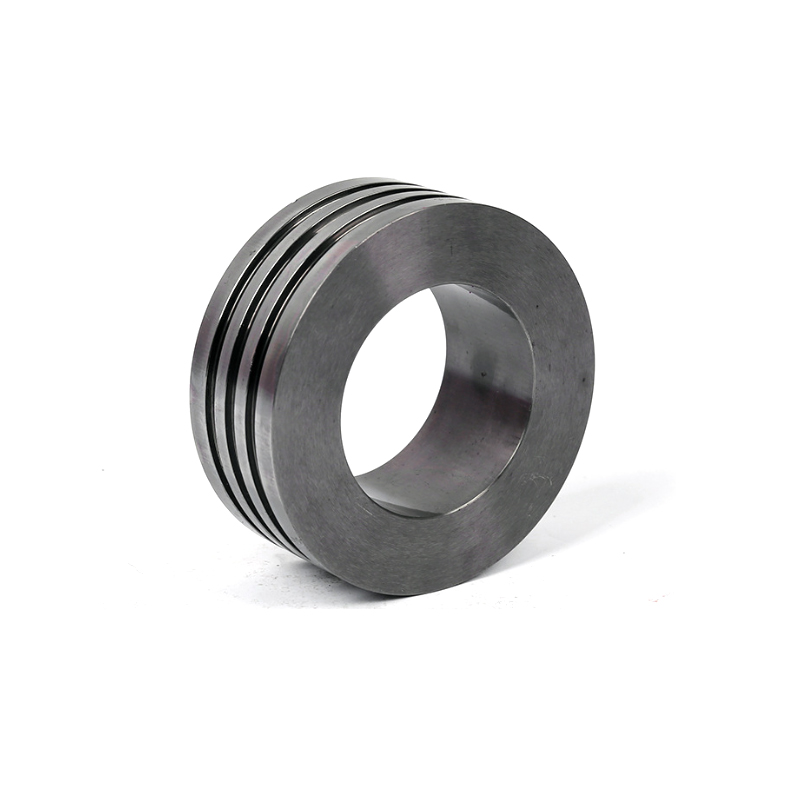

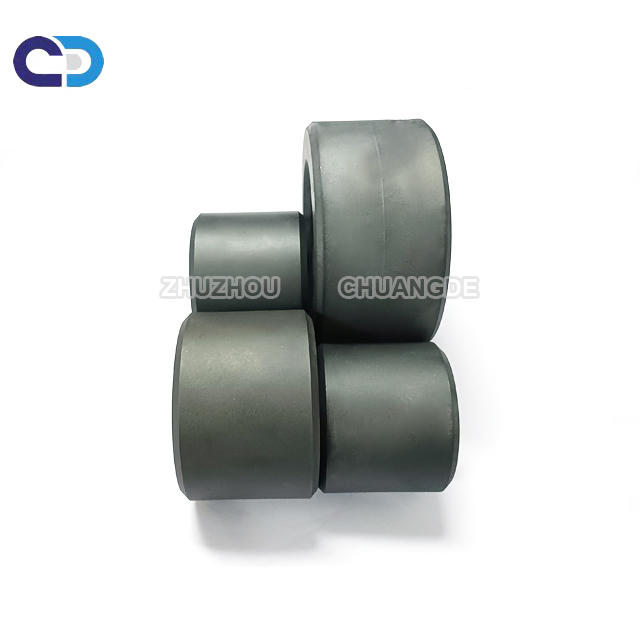

YG15 YGH30 tungsten carbide rolls for rolling mill

Meil:

Meil:

YG15 YGH30 tungsten carbide rolls for rolling mill

Good wear resistance customized cemented carbide rolls tungsten roller rings

1.Our rolls include oval reducing(RO),round reducing(RT),forming(FO)profiling(PR),sizing(CA).Other types are also available as per your requirements.

2.The rolling volume reaches 800-1500 tons one time, which is 20-50times higher than that of ordinary tool steel.

3.It can be used repeatedly by grinding, which greatly reduces the cost and significantly improves the benefit and efficiency.

Name: Tungsten carbide wire rolls

Material : Tungsten carbide, hard metal, hard alloy,tungsten steel

Composition :Tungsten carbide – TC: 80-92%, Binder – Ni+Co+Cr: 8-20%

Density: 14.0-14.8g/cm3

Hardness: HRA87-92

Features,Advantages: Wear resistant, corrosion resistant, impact resistant

Size Ranges: Outter Dia:800mm, Inner Dia≤700mm, Thickness≤400mm

Roll Types : FO,RO,RT,CA,PR

Applications(Hot Roll) Aluminium and copper wire rod reduction rollers

Applications(Cold Roll )Sizing, Forming reducing and profiling rolls are made of tungsten carbide or steel and are used to produce smooth or ribbed wire for the construction reinforcement field.

Tungsten carbide is a kind of hard alloy, the main components is tungsten carbide and cobalt, the hardness can reach 89~95HRA, with a series of excellent properties such as high hardness, high wear resistance, high strength, high toughness, high heat resistance and high corrosion resistance.

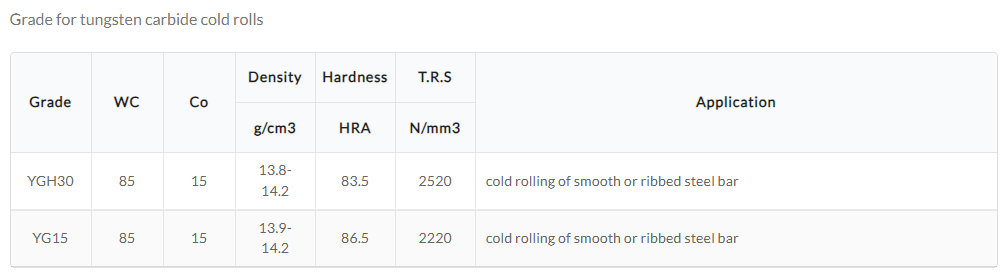

Grade and Size

Grade & Mechaical Properities

Nickel Grade Chart

Grade | Binder(Wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

YN6 | 6 | 14.7 | 89.5 | 1460 |

YN6X | 6 | 14.8 | 90.5 | 1400 |

YN6A | 6 | 14.8 | 91.0 | 1480 |

YN8 | 8 | 14.6 | 88.5 | 1710 |

Cobolt Grade Chart

Grade | Binder(Wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

YG6 | 6 | 14.8 | 90 | 2400 |

YG6X | 6 | 14.9 | 91 | 2300 |

YG6A | 6 | 14.9 | 92 | 2000 |

YG8 | 8 | 14.7 | 89.5 | 2800 |

YG12 | 12 | 14.2 | 88 | 2900 |

YG15 | 15 | 14.0 | 87 | 3000 |

YG20 | 20 | 13.5 | 85.5 | 2850 |

| No. | Outer diameter (mm) | Inner diameter (mm) | Height (mm) |

| 1 | 70 | 60 | 12 |

| 2 | 80 | 70 | 12 |

| 3 | 90 | 82 | 12 |

| 4 | 90 | 85 | 8 |

| 5 | 95 | 90 | 5.5 |

| 6 | 100 | 90 | 12 |

| 7 | 110 | 100 | 12 |

| 8 | 120 | 110 | 12 |

| 9 | 130 | 120 | 12 |

| 10 | 135 | 130 | 5.5 |

| 11 | 165 | 155 | 16 |

| 12 | 150 | 140 | 15 |

| 13 | Other customized size is also available | ||

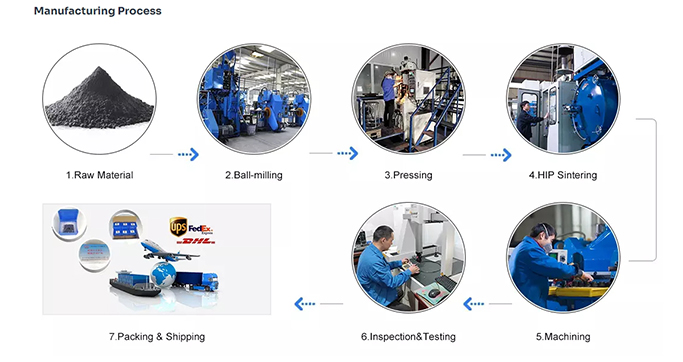

How to make tungsten carbide rolls

powder milling → formula according to grade→ wet grinding → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain a mixture → granulating → pressing → forming → Sintering →preforms→rough machining by flat grinding→non-destructive ultrasonic flaw detection →finishing machining by flat grinding→internal grinding →external grinding→chamfering→notching machining→laser marking→inspection →packing → Storage

KKK:

Q1: kas olete tehas või kaubandusettevõte?

Oleme 12-aastase tootmiskogemusega tehas.

Q2: kus teie tehas asub?

Asume Hunani provintsis Zhuzhou linnas, kus asub volframkarbiidi baas.

Q3: kas hind on konkurentsivõimeline?

Meil on oma tehas. Tänu tugevale tootmis- ja turustussüsteemile lubame pakkuda oma klientidele kõige konkurentsivõimelisemat hinda.

Q4: Kas tooted on kvaliteetsed?

Jah. Kõiki tooteid testitakse enne hulgitootmist ning enne saatmist kontrollime kvalifitseeritud toodete füüsilisi omadusi, kuju ja tolerantsust.

Võtke minuga julgelt ühendust:

Aimee

Müügijuht

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuani rajoon, Zhuzhou linn.

Meil:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688

SEOTUD TOOTED

SAADA MEILE MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Lisama215, hoone 1, rahvusvaheliste üliõpilaste pioneeripark, Taishan Road, Tianyuani piirkond, Zhuzhou linn

SAADA MEILE MAIL

AUTORIÕIGUS :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy