CATEGORIES

CUNTATTA CI

G20 G30 YG15 Tungsten carbide plates block board with sharp edge for cutting tools

E-mail:

E-mail:

G20 G30 YG15 Tungsten carbide plates block board with sharp edge for cutting tools

Product Description

Tungsten Carbide Plates YG11 YG15 YG18 Hip sintering Features

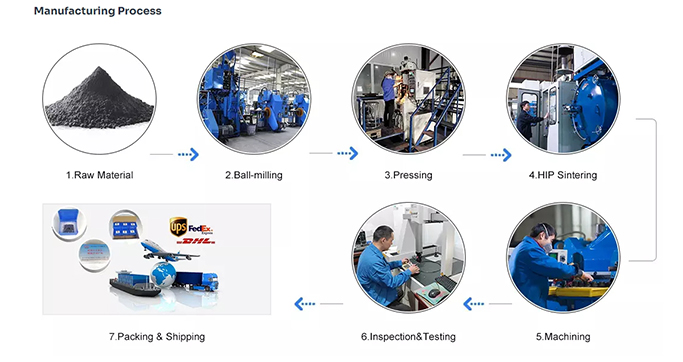

1. 100% virgin tungsten carbide materials.

2. HIP Sintering and ground surface.

3. Composition: WC+Co, WC+TiC+TaC+Co.

4. ISO9001:2015 vertified professional manufacturer over 12 years.

5. OEM and ODM are accepted as well.

Tungsten carbide strip/plate can be used in many field such as woodworking, machining of refractory alloys, stainless steel, high manganese steel, for processing cast iron, non-ferrous metal and aluminum section bar,etc

1. To make punching dies: It can be applied to the production of high-speed die and multi-station progressive die for punching copper, aluminum, stainless steel, cold-rolled sheet, hardware, standard parts, upper and lower punches, etc.

2. To make wear-resistant tools.

3. To make high temperature resistant parts, wear parts and anti-shielding parts. such as the guide rail of the machine tool and the anti-theft reinforcement board of the ATM.

4. To make corrosion-resistant parts for the chemical industry.

5. To used as radiation and corrosion resistant materials for medical equipment.

6.To do cutting tools in mold industry.

Carbide plate is a highly efficient and green material, which features qualities of stainless steel: Corrosion resistance,oxidation resistance, wear resistance, bonding proof and acid-base resistance; And ensures its good strength, toughness, bending and stretching, impact resistance.

Grade of Wear parts hard alloy widia cemented tungsten carbide board block bar plates

Grade | Properties & Applications | Approx Grades in China | |||

Density | T.R.S | Hardness | |||

g/cm3 | MPα | HRA | |||

CD8 | 14.7 | 2800 | 89.8 | High bending strength, wear resistance lower than YM6A, suitable for manufacturing forming cutter, wear-resistant parts etc. | YG8 |

CD11 | 14.4 | 2900 | 88.5 | High bending strength, wear resistance lower than YM6A, suitable for manufacturing forming cutter, wear-resistant parts etc. | YG11 |

CD15 | 14 | 3000 | 87 | Suitable for manufacturing punching dies, wear-resistant parts. | YG15 |

CD20 | 13.5 | 2800 | 85.5 | High bending strength, suitable for manufacturing progressive dies and other punching dies. | YG20 |

CD13X | 14.2 | 3200 | 90.0 | High bending strength, suitable for manufacturing progressive dies and other punching dies. | YG13X |

Application of G20 G30 YG15 Tungsten carbide plates with sharp edge for cutting tools

1.Applied on heat-resistant parts, wear-resistance parts, anti-shielding parts, anti-corrosion parts.

2.For making progressive press tools and progressive dies of high velocity ram machine.

3.For making connectors in electron industry, IC industry and semiconductor.

4.Used for armature, stator, LED lead frame, EI silicon steel sheet and punching mould for hardware and standard parts.

Dimension (mm) and shape

Length (100-500mm) *Width (100-500mm)*Thickness(1-20mm) , we will produce blanks (HIP sintering )

Tolerance : blank (L:+-1 , W:+-0.5, T :+-0.1/+/0.5 ) ,Ground :L/W/T : +/0.01, Ra 0.1

This shape is nonstandard ,we can produce according to your drawings .

FAQ:

Q1: Sò una fabbrica o una cumpagnia di cummerciale?

Semu Factory cù 12 anni di sperienza di produzzione.

Q2: Induve si trova a vostra fabbrica?

Semu situati in a cità di Zhuzhou, a pruvincia di Hunan induve hè a basa di carburu di tungstenu.

Q3: Hè u prezzu cumpetitivu?

Avemu a nostra propria Fabbrica. Grazie à u forte sistema di pruduzzione è distribuzione, prumettimu di offre à i nostri clienti u prezzu più competitivu.

Q4: Sò i prudutti di alta qualità?

Iè. Tutti i prudutti seranu pruvati prima di a pruduzzione in massa, è cuntrolleremu e proprietà fisiche, a forma è a tolleranza per assicurà i prudutti qualificati prima di u trasportu.

Sentite liberu di cuntattatemi:

Aimee

Manager di vendita

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, District Tianyuan, City Zhuzhou.

E-mail:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688

PRODOTTI RELATI

MANDACI MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Add215, Building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

MANDACI MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy