MGA KATEGORYA

KONTAK KAMI

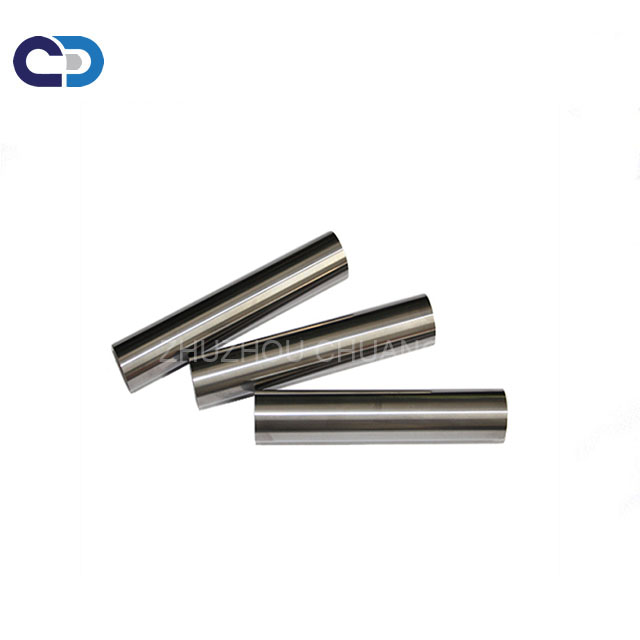

YG6X φ8*330 Polished Solid Carbide Round Bar Tungsten Carbide Rods

Email:

Email:

YG6X φ8*330 Polished Solid Carbide Round Bar Tungsten Carbide Rods

YG6X φ8*330 Polished Solid Carbide Round Bar Tungsten carbide rods

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer's application.

3. we have professional advanced production line and inspeciton equipments to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

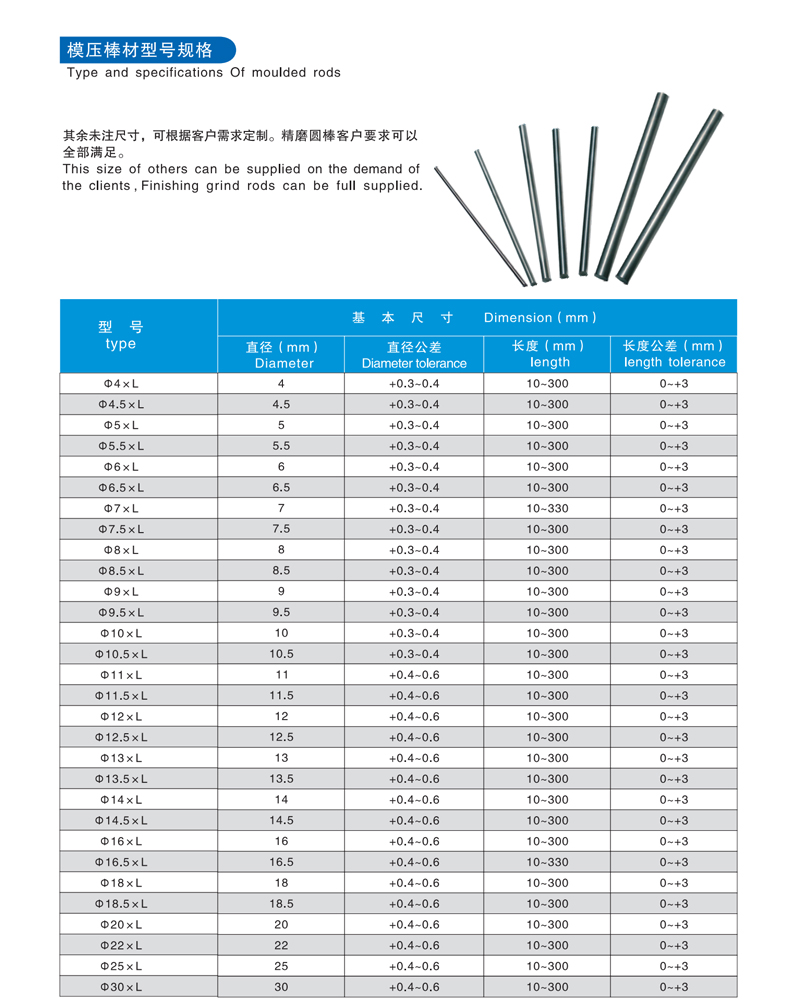

Dimension

1. Type Specification: ØD×L

2. Application: for making cutting tools, for example end mills, dental burs, reamer etc.

3. Chemical composition: 10%Cobalt,12%Cobalt and other as you need.

4. Physical properties: Density: 14.45g/cm3, TRS> 3800 MPA, Hardness> 92.00HRA

5.Surface treatment Polished to h6 Tolerance or Blanks( ungrounded), both OK.

6.Grain size : 0.2u 0.4u 0.6u 0.8u according to the grade and composite.

7. Diameter: 3mm to 30mm Length: standard 330mm/310mm or customized

| Product Name | Solid carbide rods blank and ground |

| Material | WC+CO |

| Grade | K05-K40 |

| Grain Size | fine, medium |

| Hardness | 87.6-94HRA |

| T.R.S | 3000-4200 |

| Surface | blank or ground |

| Application | Used for manufacturing cutting tools such as endmills, drills, reamers and dental burrs |

Application

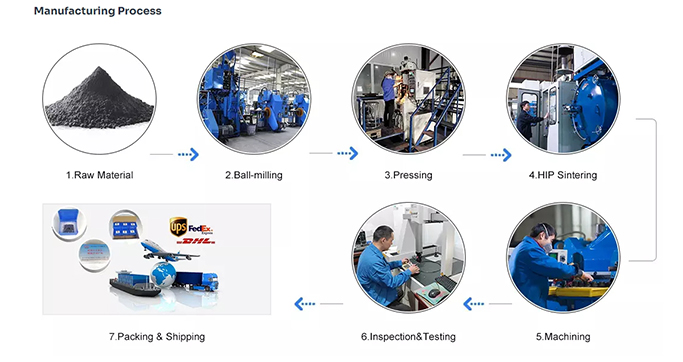

Tungsten carbide rods are mostly applied for end mill and drill with sub-micron grain grade YL10.2,for non-ferrous precision cutting and wood cutting with sub-micron grain grade YG6X,and for fibreglass reinforced plastics,titanium alloys,hardened steel with ultra-fine grain grade YG8X,ECT. It maintains features as stable mechanical properties, easy to welding, high wear-resisting, etc. All of our tungsten Carbide Products are made from the high-purity Original/Virgin Raw Materials and HIP/Sintered, be of very high quality and excellent performances.

| Grade | ISO | Grain size | Cobalt Content (wt-%) | Density g/cm3 | HARDNESS HRA | TRS (N/mm2) | APPLLICATION |

| K10UF | K05-K10 | 0.6 | 6.0 | 14.8 | 94 | 3800 | Ultrafine grain size,with good wear resistant.higher wear resistant endmill and engraving tools are recommended.suitable for cutting PCB and plastic. |

| CD6 | K10 | 1.0 | 6.0 | 14.95 | 92 | 3000 | Drilk endmill and burr are recommended.Especially suitable for cutting non-ferrous metal and graphite(coating is needed). |

| K20UF | K20 | 0.7 | 8.0 | 14.6 | 92.5 | 3200 | For cutting of the aluminum specially . |

| K40UF | K30 | 0.6 | 10 | 14.4 | 91.8 | 3000 | Drill and endmill are recommended. Suitable for cutting stainless steek heat resistant alloy and cast iron. |

| CD15 | K40 | 1.5 | 15 | 14 | 87.6 | 4000 | Suitable for making punching of moulds、tools and anti -vibration boring bar etc. |

Dimension

Without holes OD3-30*100/110/300/330mm h6 ground polished

FAQ:

Q1: Pabrika ka ba o kompanya sa pamatigayon?

Kami ang Pabrika nga adunay 12 ka tuig nga kasinatian sa produksiyon.

Q2: Asa nahimutang ang imong pabrika?

Kita nahimutang sa Zhuzhou siyudad, Hunan lalawigan diin mao ang base sa tungsten carbide.

Q3: Competitive ba ang presyo?

Kami adunay kaugalingon nga Pabrika. Salamat sa lig-on nga sistema sa produksiyon ug pag-apod-apod, kami nagsaad nga itanyag sa among mga kostumer ang labing kompetisyon nga presyo.

Q4: Taas ba nga kalidad ang mga produkto?

Oo. Ang tanan nga mga produkto pagasulayan sa wala pa ang kadaghanan nga produksiyon, ug among susihon ang pisikal nga mga kabtangan, porma ug pagkamatugtanon alang sa pagsiguro sa mga kwalipikado nga mga produkto sa wala pa ipadala.

Palihug kontaka ako:

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Distrito, Zhuzhou City.

Email:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

KAUGNAY NGA MGA PRODUKTO

PADALA KAMI MAIL

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Idugang215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

PADALA KAMI MAIL

COPYRIGHT :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy