Mga kategoriya

Kontaka kami

Ang Taas nga Pressure sa Paghimo ug Pabrika Paggama sa Grupo Hpgg Tombsen Studs

Email:

Email:

Ang Taas nga Pressure sa Paghimo ug Pabrika Paggama sa Grupo Hpgg Tombsen Studs

Ang suplay sa pabrika yg11 Yg20 Tungsten Stud sa Carbide alang sa HPGRGRENTE nga mga bahin sa carbide

Hulagway

Grado: Yg11c, Yg13C, YG15, YG20

Mga Advatages: Taas nga pagsukol sa pagsukol ug taas nga compressive kusog, kahusayan sa trabaho

Kinabuhi sa Serbisyo: 8000-10000 HRS alang sa iron ore crushing ug sobra sa 25000hrs alang sa crushing sa semento

Kami adunay mga propesyonal nga mga inhenyero nga maghimo sa pagguhit matag kinahanglanon sa kustomer:

nga adunay gidak-on sa produkto, makahatag kita og drowing.

nga adunay sample nga gihatag sa amon, makahatag kami nga drowing.

nga adunay litrato sa produkto, makahatag kami nga drowing.

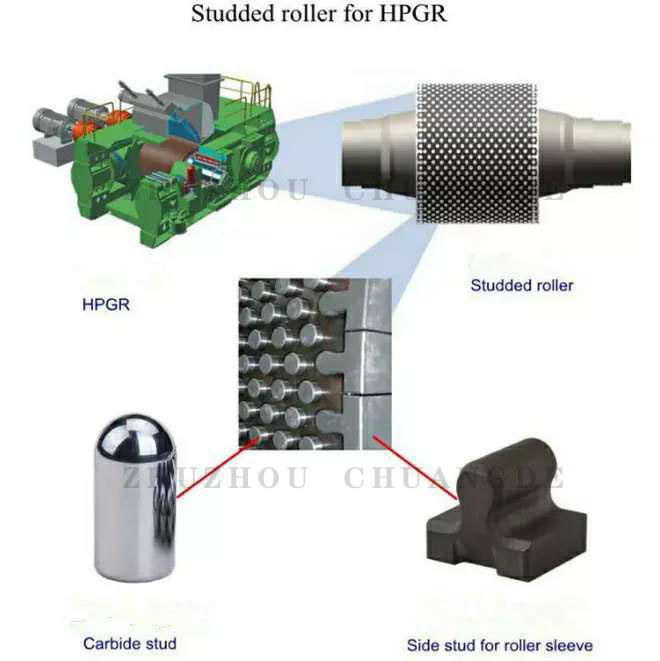

Paggamit sa semento nga stud sa carbide alang sa HPGRGGR GRUPTE ORE ug CEENSE

Ang high pressure nga paggaling sa roller usa ka episyente nga pag-crush sa mga bag-ong teknolohiya, nga gigamit sa pag-agay sa semento sama sa mga nag-unang kagamitan sa pag-agay sa mga gamit nga semento sama sa mga pang-core sa core sa panguna nga mga kagamitan Ang pasundayag niini direkta nga nagtino sa kahusayan sa output sa linya sa produksiyon. Ang taas nga pasundayag sa stud sa carbide nagpalapad sa kinabuhi sa taas nga presyur nga paggiling roller. Naghatag ang Zuzhou Chuangde nga kalidad nga mga stud sa carbide nga adunay maayo nga pagsukol sa pagsukol ug taas nga kusog nga kusog, makatagbaw sa mga kinahanglanon sa lainlaing mga kahimtang.

Atong Mga Kausaban:

1.HEHEMPHERICALOTICAL TOP, pagpanalipod sa mga estudyo gikan sa pag-awas sa konsentrasyon sa stress.

2. Pag-agos sa mga sulab, panalipdan ang mga stubs nga nadaot sa panahon sa produksiyon, transportasyon, pag-install ug paggamit.

Pagkasamok sa 3.

4.SPECECESS TECTAROOLOHIYA SA PAGPANGITA SA KASINGKASING SA SUBSET HAPON SA PAGSULAY SA PAGSULAY, ug pagdugang sa katig-a sa ibabaw sa parehas nga oras.

5.Gawas nga gigamit sa ibabaw sa mga produkto aron malikayan ang pag-okupar.

Ang mga grado sa ubos mao ang eksklusibo nga mga grado nga among naugmad alang sa rolling machine. Ang maayo nga pagsukol sa pagsul-ob ug taas nga kusog angay alang sa metal nga pagsamad sa taas nga pag-ayo sa pagtrabaho. Ang tibuok kinabuhi sa Carbide Stud mao ang kapin sa 8000-10000 HRS Iron Ore ug 25000HRS alang sa semento.

| Gradohan | Kusog (HRA) | Bending Strengh (≥n / mm²) | Density | Pagpaayo (Ka / M) | Boabbation | Karbon |

| YG15C | 85-86.5 | 2500 | 13.9-14.1 | 4.5-6.5 | 14.7-15.3 | 4.9-5.5 |

| YG20 | 86-87.5 | 2450 | 13.4-13.6 | 8.0-11.0 | 19.7-20.3 | 4.5-4.8 |

| YG15 | 87-88.5 | 2800 | 13.95-14.15 | 7.0-10.0 | 14.1-14.8 | 4.95-5.6 |

| CD650 | 87.8-90 | 2950 | 13.95-14.15 | 8.0-10.5 | 14.5-14.9 | |

| CD20 | 85.8-87.3 | 2600 | 13.89-14.2 | 5.8-8.0 | 14.8-15.2 |

Ang tanan nga mga produkto kinahanglan nga susihon hugot sa ultrasonic ug kadtong mga wala'y kadaut sama sa lungag mahimo nga ipadala. Taas nga Densidad, Pagsul-ob sa Taas nga Pagsul-ob ug epekto sa pagsukol, nga nagdala kanila usa ka taas nga kinabuhi.

Alang sa pagdugmok sa taas nga presyur nga paggiling roller, iron ore, crush sa semento

Deskripsyon sa Produkto: Ang TungsTen Carbide Stud Pins nag-una nga gigamit alang sa taas nga presyur nga paggiling roller nga HPGR

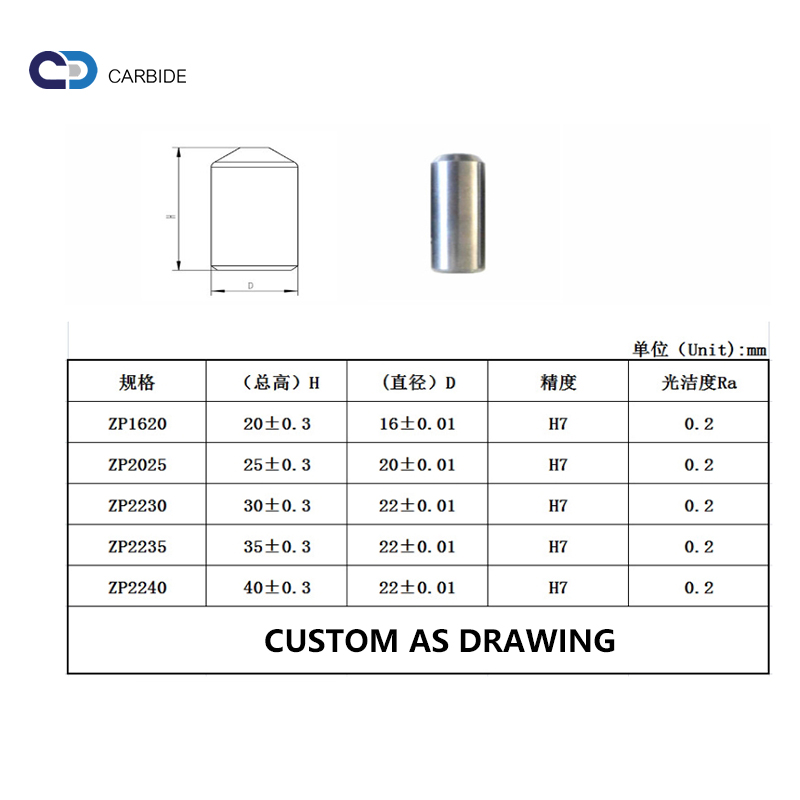

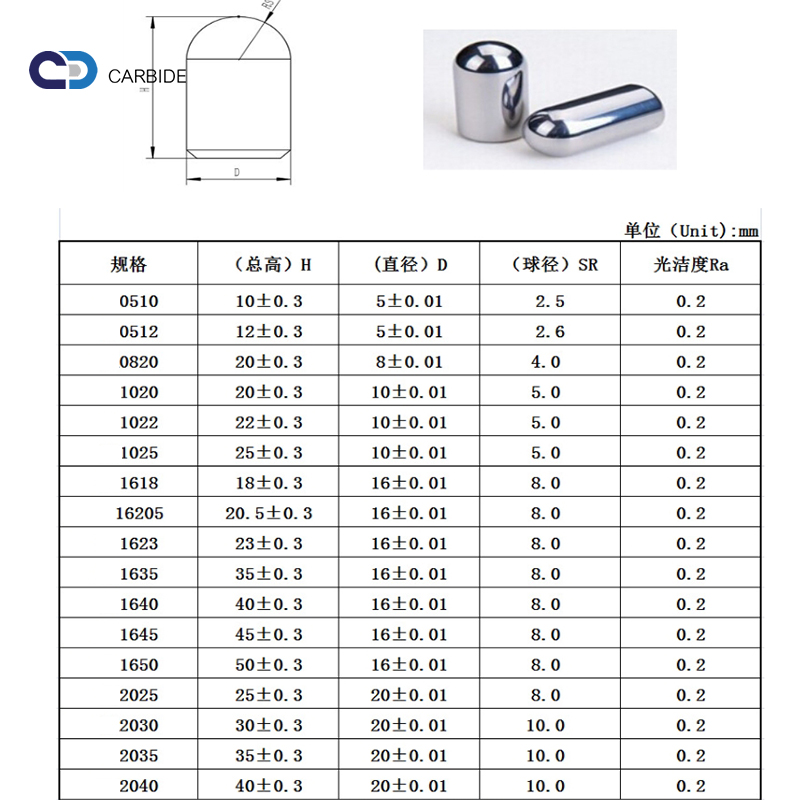

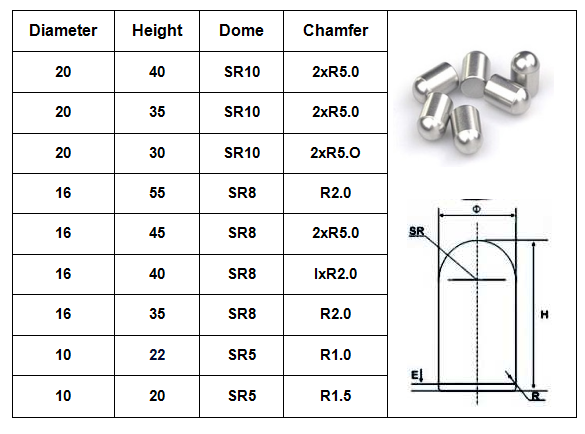

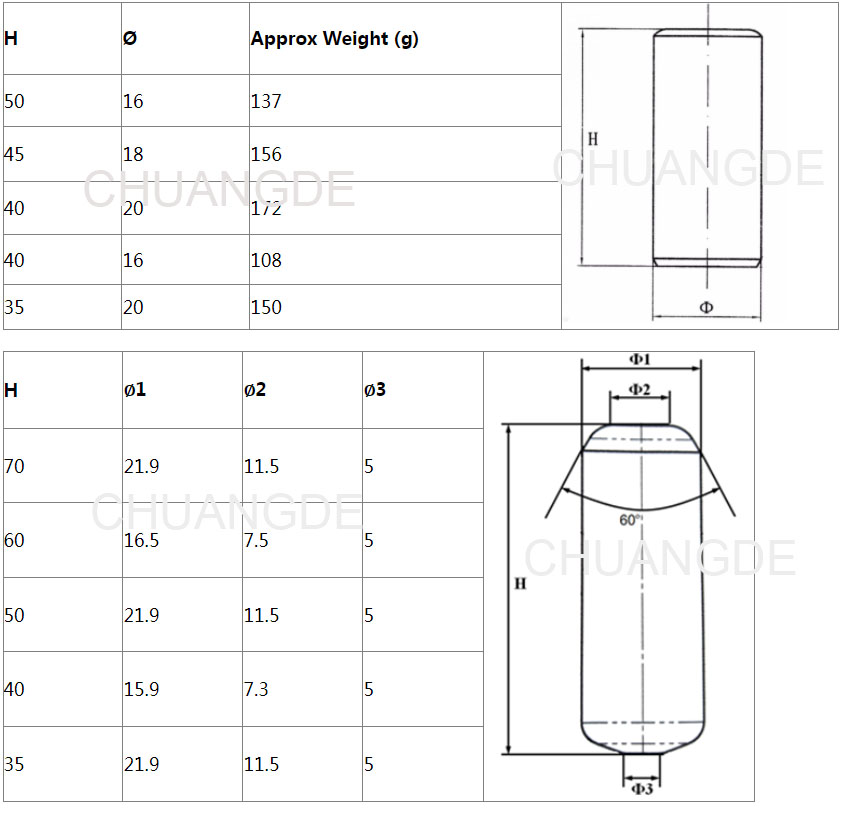

Mga sukat

FAQ:

Q1: Pabrika ka ba o kompanya sa pamatigayon?

Kami ang Pabrika nga adunay 12 ka tuig nga kasinatian sa produksiyon.

Q2: Asa nahimutang ang imong pabrika?

Kita nahimutang sa Zhuzhou siyudad, Hunan lalawigan diin mao ang base sa tungsten carbide.

Q3: Competitive ba ang presyo?

Kami adunay kaugalingon nga Pabrika. Salamat sa lig-on nga sistema sa produksiyon ug pag-apod-apod, kami nagsaad nga itanyag sa among mga kostumer ang labing kompetisyon nga presyo.

Q4: Taas ba nga kalidad ang mga produkto?

Oo. Ang tanan nga mga produkto pagasulayan sa wala pa ang kadaghanan nga produksiyon, ug among susihon ang pisikal nga mga kabtangan, porma ug pagkamatugtanon alang sa pagsiguro sa mga kwalipikado nga mga produkto sa wala pa ipadala.

Palihug kontaka ako:

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Distrito, Zhuzhou City.

Email:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688

May Kalabutan nga mga Produkto

Padalhan kami sa mail

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Modugang215, building 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

Padalhan kami sa mail

Mag-copyright :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy