27

2024

-

06

How to choose suitable carbide strips and plates

Cemented carbide strips, also known as cemented carbide strips, are mainly made of WC tungsten carbide and Co cobalt powders mixed by metallurgical methods through powder making, ball milling, pressing and sintering. The content of WC and Co in cemented carbide strips for different purposes is not consistent. It has the characteristics of high red hardness, good weldability, high hardness, high wear resistance, and a wide range of uses.

Its main performance characteristics include: good hardness, high hardness, good wear resistance, high elastic modulus, high compressive strength, good chemical stability (acid, alkali, high temperature oxidation resistance), low impact toughness, low expansion coefficient, thermal conductivity and electrical conductivity are similar to iron and its alloys.

Cemented carbide plate is a plate made of cemented carbide material.

It has the characteristics of high hardness, high strength, good wear resistance, and high temperature resistance. The composition of common cemented carbide plates is mainly tungsten carbide (WC) and cobalt (Co), and may also contain other alloy elements to improve specific properties.

Differences:

1.Carbide strips are usually in the form of long strips, with a relatively large length and a relatively narrow width and thickness. Features include:

It is often used to make the blade of cutting tools, such as turning tools, milling cutters, etc., and is installed on the tool bar by welding or clamping.

Due to its long strip shape, it can play an advantage in some occasions where long and narrow wear-resistant parts are required.

2.Carbide plates are generally in the form of plates, with relatively large length and width, and relatively thin and uniform thickness. Features include:

It is more used in key parts of molds, such as punches and dies of stamping molds, which are subject to greater pressure and friction.

It is also suitable for manufacturing some parts that require large-area wear resistance, such as wear-resistant pads for machine tool guides.

When choosing carbide strips or plates, it is necessary to comprehensively consider factors such as specific usage scenarios, processing requirements,

and stress conditions to ensure that the excellent performance of carbide materials can be fully utilized to meet production and processing needs.

Advantages of Carbide Strips and Plates:

Advantages of carbide strips:

1. Good cutting performance: suitable for manufacturing the cutting edge of various cutting tools, and can achieve efficient and precise cutting processing.

2. The strip shape is easy to install and position: in tool manufacturing, it is easy to connect and fix with the handle or tool body to ensure the stability of the tool during work.

3. Strong targeting: the size, shape and angle of the strip can be customized according to specific cutting needs to achieve the best processing effect.

Advantages of carbide plates:

1. Larger plane area: can provide a wider contact surface, suitable for mold parts that withstand greater pressure and friction, and improve the durability of the mold.

2. High flatness and dimensional accuracy: conducive to ensuring stability and accuracy in use, suitable for occasions with high precision requirements.

3. Easy to process into complex shapes: can be processed into various special shapes of parts through wire cutting, grinding and other processes according to specific application requirements.

4. Good wear resistance: can maintain the integrity of the surface during long-term use, reducing frequent replacement and maintenance due to wear.

How to choose suitable carbide strips and plates:

When choosing the grade of carbide strips:

1. The nature of the material being processed: For materials with higher hardness, such as hardened steel, grades with higher hardness and better wear resistance, such as YT15 and YT30, are usually selected. When processing brittle materials such as cast iron, grades such as YG8 and YG6 may be more suitable because they have better impact resistance.

2. Cutting conditions: Under conditions of high cutting speed and large feed rate, grades with good heat resistance, such as YT, need to be selected. When cutting at low speed and heavy weight, the toughness of YG grades can play a better role.

3. Processing accuracy requirements: For processing with higher precision requirements, grades with high hardness, good wear resistance and good dimensional stability should be selected.

4. The shape and size of the tool: Slender tools may require grades with higher bending strength to prevent breakage.

When choosing the grade of carbide plate:

1. Application scenarios and working conditions: If the plate is used in conditions that are subject to high pressure and strong impact, such as stamping dies, grades with higher toughness and impact resistance should be preferred, such as YG20, YG25, etc. For applications that work in high temperature environments and require good wear resistance, such as some hot working dies, grades with better heat resistance such as YT30 may be more suitable.

2. Characteristics of the processing object: When processing materials with higher hardness, grades with excellent hardness and wear resistance need to be selected. For example, when processing hardened steel, YT15 can be considered. When processing brittle materials, more attention is paid to anti-cracking performance, and YG grades may be a better choice.

3. Precision and surface quality requirements: For applications with extremely high requirements for processing precision and surface quality, grades with high hardness, uniform structure and good dimensional stability need to be selected.

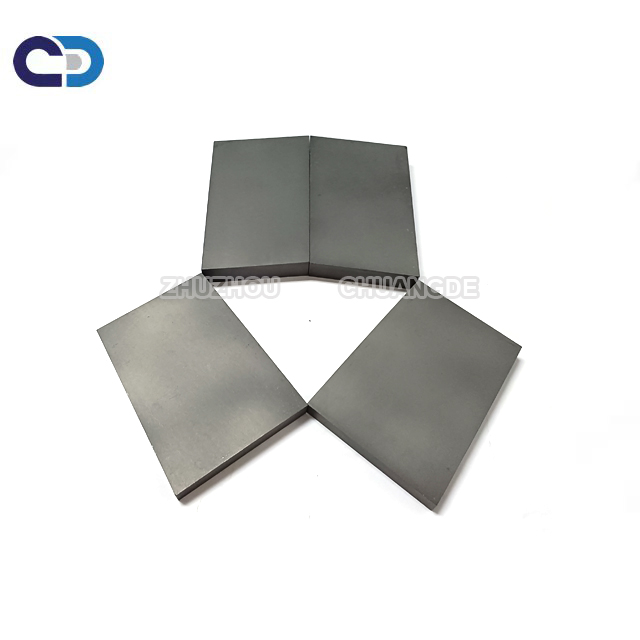

Our Product Show:

NOTÍCIES RELACIONADES

Zhuzhou Chuangde Cemented Carbide Co., Ltd

Afegeix215, edifici 1, International Students Pioneer Park, Taishan Road, Tianyuan District, Zhuzhou City

ENVIA'NS UN CORREU

DRET D'AUTOR :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy