KATEQORİYALAR

BİZİMLƏ ƏLAQƏ SAXLAYIN

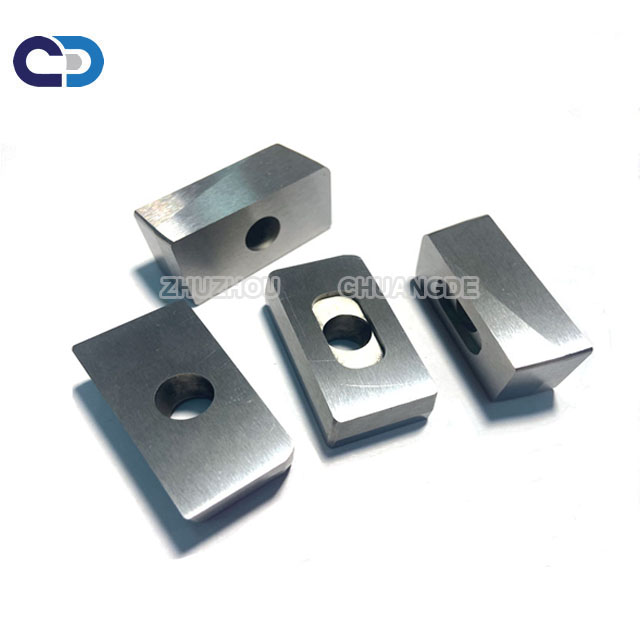

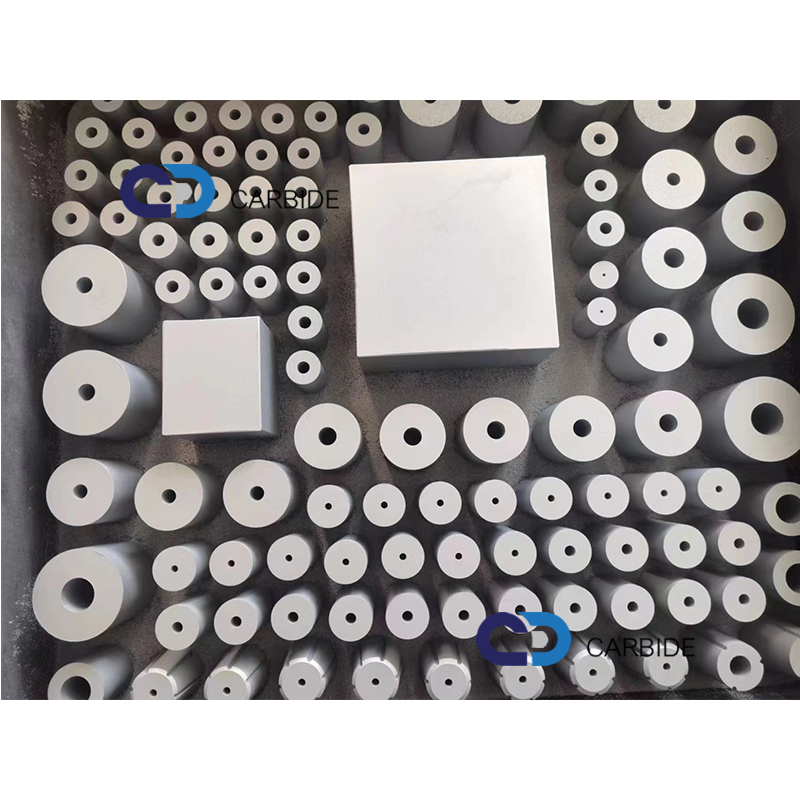

Manufacturers Customized Hot Forging Tungsten Carbide Cold Heading Stamping Dies for screws

E-poçt:

E-poçt:

Manufacturers Customized Hot Forging Tungsten Carbide Cold Heading Stamping Dies for screws

Description

Surface: Grinding, Polishing, Sand-blasted

Application: for making bolt and nuts

Features: Good wear resistance, impact resistance, High bending strength

Grade: YG15, YG20, YG20C, YG22C, YG25C, GT55, ML40, ML100, ST7, VA90, C5

Performance: TRS > 3000 N/mm3, Hardness: 85-92HRA

Advantage

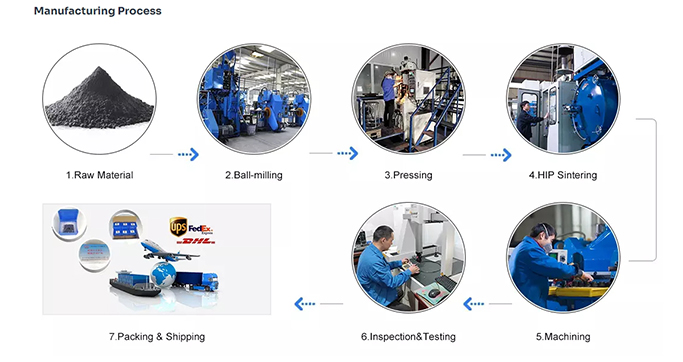

1.100% raw material for production.

2.Hip sintered, reliable hardness, durable wear resistance

3.Various sizes, carbide grade and full types available

4. Competitive price with on-time delivery

5.Customized product as per drawing and small order accepted,professional and in-time technical support

Applications :

Tungsten carbide pellets dies are widely used in cold heading,forging,stamping and punching dies for maufacturing nuts, screw caps, bolts, cans and many other products.

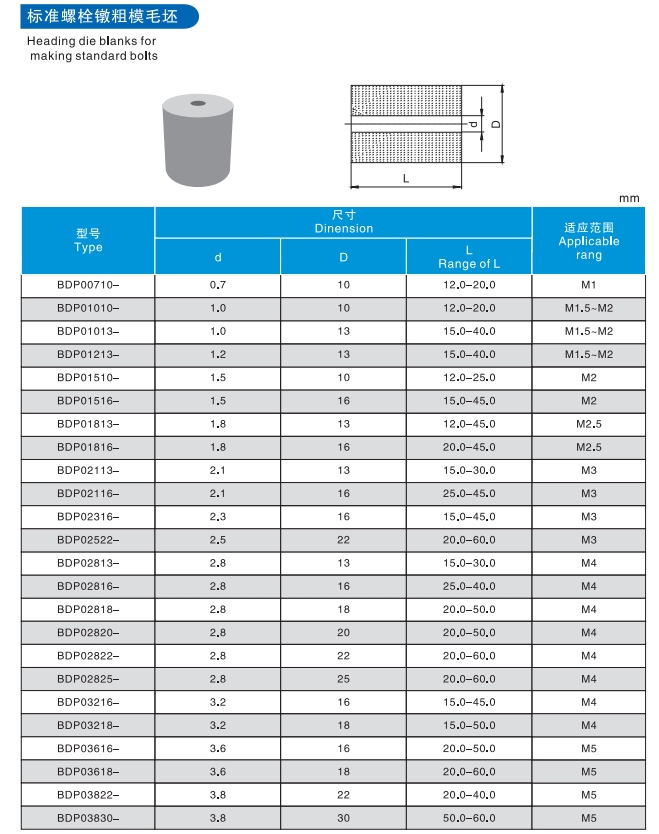

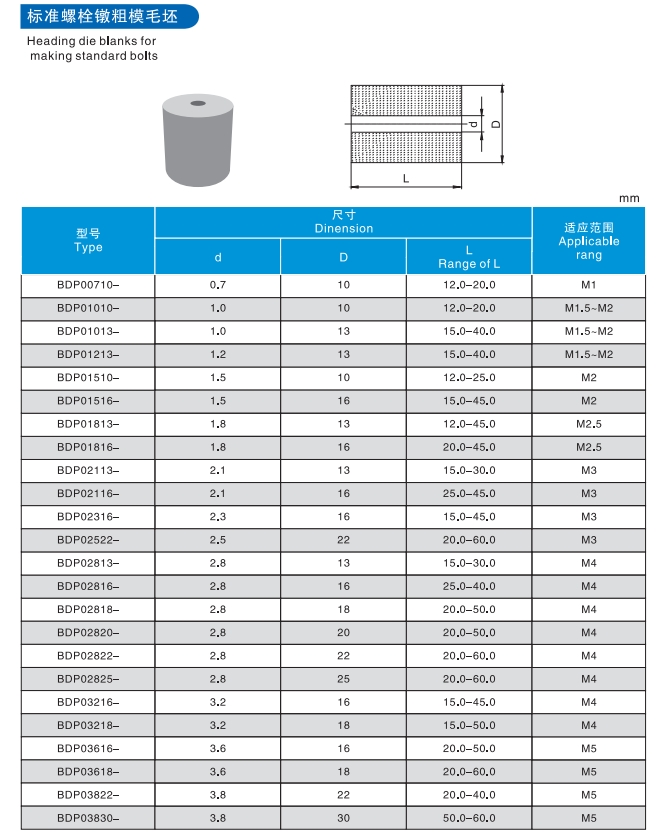

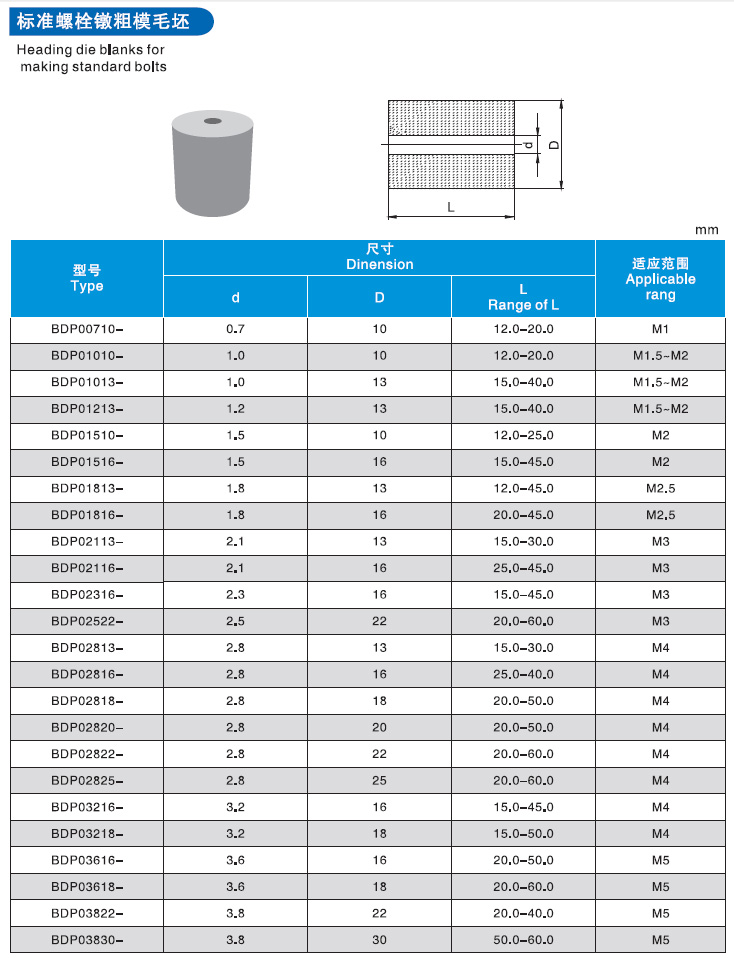

Commonly used tungsten carbide heading dies

Carbide punching and impacting dies | |||||

Grade | Performance | Performance&application recommended | |||

Density | Hardness | Bend Strength | |||

G/Cm3 | HRA | N/mm2 | |||

YG11 | 14.4 | 88.5 | 2600 | Forming or stamping dies for metal powders and nonmental powders. | |

YG15 | 14 | 87.5 | 2800 | For fabricating drawing dies of steel tubesand rods under high | |

compressibility ratio;punching,stamping,forging tools under large stress. | |||||

YG20 | 13.5 | 85.5 | 3200 | For fabricating of stamping dies for watch parts, spring plates of musical | |

instruments, battery jars,small sized steel balls,screws,screw caps. | |||||

YG16C | 13.9 | 85.5 | 2900 | Impact resistance, hot&forging dies etc. | |

YG18C | 13.7 | 84.5 | 3100 | Impact resistance forging dies,hot-press forging dies and rollers. | |

YG20C | 13.5 | 83.5 | 3300 | Dies for wear resistant or impact resistant application. | |

YG22C | 13.3 | 83 | 3500 | Nut forming dies and high impact resistance forging dies. | |

YG25C | 13.1 | 82.5 | 3600 | Stainless bolt header dies and rollers. | |

Features

1) Extension of die life and stability of life

By controlling the particle size distribution of WC, can make the plastic deformation and reduce the load of thecemented carbide to improve the compressive strength and fracture toughness, delaying the occurrence and propagation of cracks of the mould process, long service life, and has a very high consistency.

2)Bite and adhesion decreased considerably

High temperature single crystal WC was used to strengthen the binding of crystalline structure and effectively strengthen the cobalt phase, thus effectively inhibiting the cracking of the material.

3)The corrosion resistance and electrical resistance of the cemented carbide are improved

Because of the strengthening of the cobalt phase, the corrosion resistance of the cemented carbide is greatly improved, so that the cemented carbide is suitable for discharge machining.

Tez-tez verilən suallar:

Q1: Siz zavod və ya ticarət şirkətisiniz?

Biz 12 illik istehsal təcrübəsinə malik fabrikik.

Q2: Fabrikiniz harada yerləşir?

Biz volfram karbidinin əsası olan Hunan əyalətinin Zhuzhou şəhərində yerləşirik.

Q3: Qiymət Rəqabətlidirmi?

Bizim öz zavodumuz var. Güclü istehsal və paylama sistemi sayəsində biz müştərilərimizə ən rəqabətli qiyməti təklif etməyə söz veririk.

S4: Məhsullar yüksək keyfiyyətlidirmi?

Bəli. Bütün məhsullar toplu istehsaldan əvvəl sınaqdan keçiriləcək və göndərilməzdən əvvəl keyfiyyətli məhsulların təmin edilməsi üçün fiziki xassələri, forma və tolerantlığı yoxlayacağıq.

Mənimlə əlaqə saxlamaqdan çekinmeyin:

Aimee

Satış meneceri

Zhuzhou Chuangde Semented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Rayonu, Zhuzhou Şəhəri.

E-poçt:info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688

ƏLAQƏDAR MƏHSULLAR

BİZƏ MAIL GÖNDƏRİN

Zhuzhou Chuangde Cemented Carbide Co., Ltd

əlavə et215, bina 1, Beynəlxalq Tələbələr Pioner Parkı, Taishan Yolu, Tianyuan rayonu, Zhuzhou şəhəri

BİZƏ MAIL GÖNDƏRİN

Müəllif Hüququ :Zhuzhou Chuangde Cemented Carbide Co., Ltd

Sitemap

XML

Privacy policy