ምድቦች

እኛን ያግኙን

የአምራች ጠንካራ መጋገሪያ አሞሌ የ Crundar Cardide Cards Tungry Cardodite Chedoge

ኢሜል:

ኢሜል:

የአምራች ጠንካራ መጋገሪያ አሞሌ የ Crundar Cardide Cards Tungry Cardodite Chedoge

የአምራች ጠንካራ መጋገሪያ አሞሌ የ Crundar Cardide Cards Tungry Cardodite Chedoge

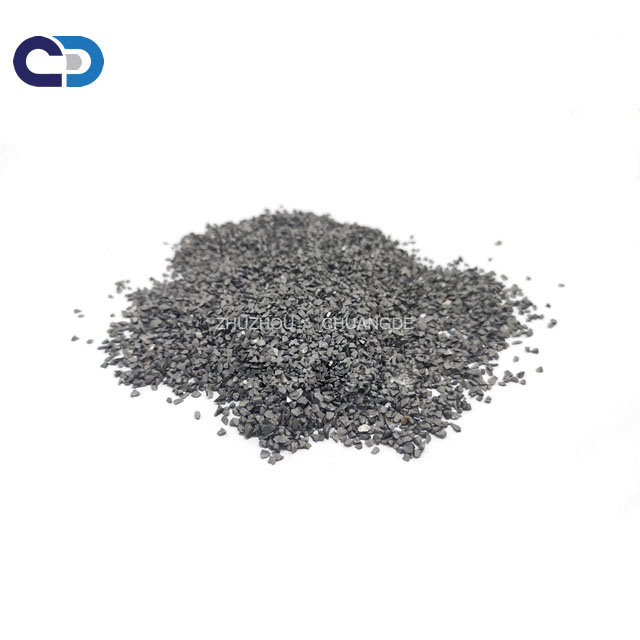

የ Sungren Cardoide የመዳብ ብራዙን የ SCRAP ደረጃ እና ባለ ቀለም የተሠራው የ Scrasphing Trance Scrasp ነው. እስከ 690MMA, ጠንካራነት HB≥160.

| ክፍል | የኬሚካል ጥንቅር (WT%) | |||

| Ni + Cu + ZN + SN | Cu + ZN + ቁ | WC | Co | |

| Cu-30 | -- | 30±2 | 63-65 | 5.2-6.0 |

| Cu-40 | -- | 40±2 | 53-56 | 4.6-4.8 |

| Cu-45 | -- | 45±2 | 48-52 | 4.2-4.5 |

| Cu-50 | -- | 50±2 | 44-48 | 3.8-4.2 |

| Ni-Cu-30 | 30±2 | -- | 63-65 | 5.2-6.0 |

| Ni-Cu-40 | 40±2 | -- | 53-56 | 4.6-4.8 |

| Ni-Cu-45 | 45±2 | -- | 48-52 | 4.2-4.5 |

| Ni-Cu-50 | 50±2 | -- | 44-48 | 3.8-4.2 |

| ሜትሪክ (ሚሜ) | ኢንች | |

| የእህል መጠን | 1.6-3.2 | 1/16”-1/8” |

| 3.2-4.8 | 1/8”-3/16” | |

| 4.8-6.4 | 3/16”-1/4” | |

| 6.4-8.0 | 1/4”-5/16” | |

| 8.0-9.5 | 5/16”-3/8” | |

| ልዩ ቅርፅ የሰበረ የቱናል የ Cunds Cards ምክሮች | ||

| መጠን በደንበኛው ጥያቄ ሊሠራ ይችላል. | ||

ምርት የ የአምራች ጠንካራ መጋገሪያ አሞሌ የ Crundar Cardide Cards Tungry Cardodite Chedoge

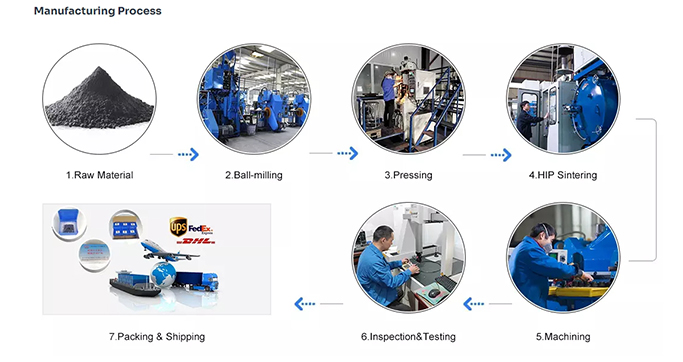

ኦክሲካይይቲቭ ግን ኦፕሬቲንግ ሂደት እንደሚከተለው ነው-

(1) የሥራውን ክፍል ያፅዱ, የሽፋኑ የሥራ ቦታዎችን ወለል በብረታ ብረት ውስጥ ያድርጉት.

(2) የመገጣጠም ጠፍጣፋ አቀማመጥ ስለዚህ, ስለሆነም የሚገኘውን ጠፍጣፋ ንጣፍ ውፍረት, ወፍራም ቁራጭ ለመቆጣጠር ተገቢውን የማጭበርበር ውድቀት መጠቀም ይችላል.

(3) ገለልተኛ ነበልባል ሰፋሪ, ነበልባል ዋና ያልሆነ ወለል, እስከ 25 ሚሜ ርቀት የሚመከር ነው.

(4) የካርበሪድ ክምችት ቀልጥ ያለ ብረት ጠንካራነት, ቅንጣቶች በዲዛይን በሚሰጡት መሠረት በግራፊክ በትር ላይ የተቆራረጠ ኤሌክትሮድን ወይም የግራ እጅን የግራ እጅ ኤሌክትሮይን የሚይዝ ወይም በሌላኛው ሰው የተቆራኘውን የግራ መሣሪያውን ወይም ሌላ ሰው ሊጠቀም ይችላል.

(5) አየር ማረፊያ, ዘገምተኛ ማቀዝቀዝ ከሌለበት ከስራ ውጭ ከሆነው ከስራ ውጭ ከሆነ በኋላ ሁኔታዊ ያልሆነ የአስቤስቶስ ብርድልብስ ሽፋን.

(6) አስፈላጊ ከሆነ አስፈላጊ ከሆነ አስፈላጊ ከሆነ ወደ ክፍሉ የሙቀት መጠን ከቀዘቀዘ በኋላ, አስፈላጊ ከሆነ እና ቅርፅ ያለው.

(7) የሥራውን ማንጸባረቅ, ሁሉንም SPLASH, Clasg, ወዘተ ያስወግዱ.

የአምራች ትግበራ ትግበራ የ Sungnster Cardide Cardide Tregs Tungsity Cardodity Checking Checkion Chedoge

የ YG ተከታታይ የ Cardide Carabing RD በዋነኝነት የሚያገለግለው በዋነኝነት የሚጠቀሙበት ወይም የተቆረጡ የሥራ ባልደረባዎች ውስጥ ነው

እንደ ወፍጮ ጫማ, ጫማዎች, ማዕከላት, ማዕከላት, ማዕከላት, ማዕከላት, ማዕከላት, ማዕከላት, ማዕከላት, ማዕከላት, ማዕከላት, ማዕከላዊ እና ሌሎች ኢንዱስትሪዎች, የድንጋይ ን ግንባታ, የድንጋይ ን ግንባታ, የድንጋይ ከሰል ቢት, የድንጋይ ንጣፍ ቢት, የድንጋይ ንጣፍ ማሸጊያዎች, የድንጋይ ንጣፍ ማጠራቀሚያዎች, የድንጋይ ንጣፍ ማሸጊያዎች, የድንጋይ ንጣፍ ማጠራቀሚያዎች, የድንጋይ ከሰል ቢት.

የሚጠየቁ ጥያቄዎች፡-

Q1: እርስዎ ፋብሪካ ወይም የንግድ ድርጅት ነዎት?

የ12 ዓመት የምርት ልምድ ያለን ፋብሪካ ነን።

Q2: ፋብሪካዎ የት ነው የሚገኘው?

የምንገኘው በዙዙ ከተማ፣ ሁናን ግዛት ውስጥ የተንግስተን ካርቦዳይድ መሠረት ነው።

Q3: ዋጋው ተወዳዳሪ ነው?

የራሳችን ፋብሪካ አለን። ለጠንካራ ምርት እና ስርጭት ስርዓት ምስጋና ይግባውና ለደንበኞቻችን በጣም ተወዳዳሪ ዋጋ ለማቅረብ ቃል እንገባለን.

Q4: ምርቶቹ ከፍተኛ ጥራት ያላቸው ናቸው?

አዎ። ሁሉም ምርቶች በጅምላ ከመመረታቸው በፊት ይሞከራሉ፣ እና ከመርከብዎ በፊት ብቁ የሆኑ ምርቶችን ለማረጋገጥ የአካላዊ ባህሪያቱን፣ ቅርፅን እና መቻቻልን እንፈትሻለን።

እኔን ለማግኘት ነፃነት ይሰማዎ:

አሚ

የሽያጭ አስተዳዳሪ

Zhuzhou Chuangde ሲሚንቶ Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

ታይሻን ሮድ፣ ቲያንዩአን አውራጃ፣ ዙዙዙ ከተማ።

ኢሜይል፡-info@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

WhatsApp/wechat/Skype፡ 0086 13786352688

ተዛማጅ ምርቶች

ደብዳቤ ይላኩልን

Zhuzhou Chuangde ሲሚንቶ Carbide Co., Ltd

ጨምር215፣ ሕንፃ 1፣ ዓለም አቀፍ ተማሪዎች አቅኚ ፓርክ፣ ታይሻን መንገድ፣ ቲያንዩአን አውራጃ፣ ዙዙዙ ከተማ

ደብዳቤ ይላኩልን

የቅጂ መብት :Zhuzhou Chuangde ሲሚንቶ Carbide Co., Ltd

Sitemap

XML

Privacy policy